Dual-drive body-in-white lifting working platform

A technology of body-in-white and workbench, which is applied in the direction of lifting frame, lifting device, lifting equipment safety device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

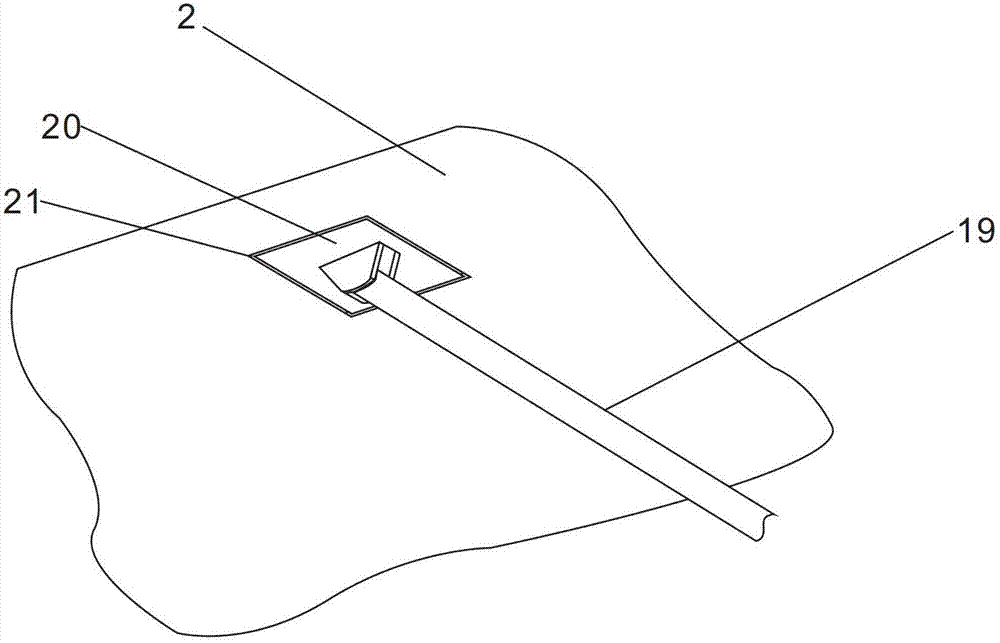

[0025] Such as figure 1 with image 3As shown, a double-drive body-in-white lifting workbench is used on an automobile welding line, including an underframe 1, a main lifting mechanism, a top platform 2 and a PLC. Described main elevating mechanism is arranged between underframe 1 and top platform 2, and this main elevating mechanism is scissors type elevating mechanism, comprises two groups of scissor arms that are made up of active arm 18 and driven arm 19, and two groups of scissor arms The yoke arms are symmetrically arranged in parallel, and the plane where the scissor arms are located is parallel to the length direction of the underframe 1. In each group of scissor arms, the middle part of the driving arm 18 is hinged with the middle part of the driven arm 19, and the two groups of driving arms 18 and the slave arms are hinged. The hinge points of the movable arms 19 are connected by a connecting rod, and a push rod is connected between the bottom ends of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com