Degradable biaxially oriented polypropylene cigarette packaging film and manufacturing method thereof

A technology of biaxial stretching and polypropylene, which is applied in the field of new polymer materials, can solve the problems of dull and yellowish degraded films, performance degradation, and difficulties in popularization, and achieve good degradability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

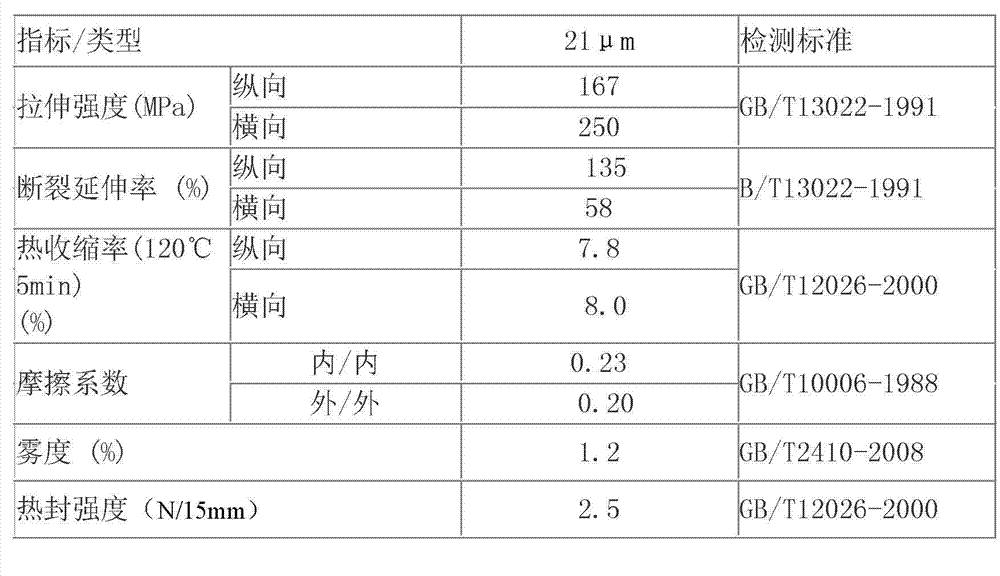

Examples

Embodiment 1

[0027] Ingredients: Produce a film with a thickness of 18 μm. The thickness of the upper layer is 0.8μm, of which the content of binary copolymerized polypropylene is 96%, 0.8% of cross-linked methyl acrylate, 2.9% of silicone, and 0.3% of sodium stearate; the thickness of the middle layer is 16.4μm, which contains 0.5~0.8% of ethylene mono The propylene-ethylene random copolymer content of the body is 73.7%, hydrogenated resin 25%, glycerol monostearate 1.0%, sodium stearate 0.3%; the thickness of the lower layer is 0.8 μm, and the content of binary copolymerized polypropylene is 98.9% , cross-linked methyl acrylate 0.8%, sodium stearate 0.3%.

[0028] Film making: The degradable biaxially stretched polypropylene cigarette film packaging film of the present invention is produced by biaxially stretching co-extrusion process, wherein the extruder temperature: 220°C; casting machine temperature: 23°C; longitudinal stretch ratio: 490 %, longitudinal stretching preheating tempera...

Embodiment 2

[0030] Ingredients: Produce a film with a thickness of 19 μm. The thickness of the upper layer is 0.9μm, of which the content of binary copolymerized polypropylene is 96.5%, 0.7% of cross-linked methyl acrylate, 2.6% of silicone, and 0.2% of sodium stearate; the thickness of the middle layer is 17.2μm, which contains 0.5~0.8% of ethylene mono The propylene-ethylene random copolymer content of the body is 78.7%, hydrogenated resin 23%, glycerol monostearate 1.5%, sodium stearate 0.2%; the thickness of the lower layer is 0.9 μm, and the content of binary copolymerized polypropylene is 99.1% , cross-linked methyl acrylate 0.7%, sodium stearate 0.2%.

[0031] Film making: The degradable biaxially stretched polypropylene cigarette film packaging film of the present invention is produced by using a biaxially stretched co-extrusion process, wherein the temperature of the extruder: 223°C; the temperature of the casting machine: 21°C; the longitudinal stretch ratio: 510 %, longitudina...

Embodiment 3

[0033] Ingredients: Produce a film with a thickness of 20 μm. The thickness of the upper layer is 1.0 μm, of which the content of binary copolymerized polypropylene is 96.5%, 0.6% of cross-linked methyl acrylate, 2.7% of silicone, and 0.2% of sodium stearate; the thickness of the middle layer is 18 μm, which contains 0.5~0.8% of vinyl monomer The content of propylene-ethylene random copolymer is 78.7%, hydrogenated resin is 22%, glycerol monostearate is 1.0%, sodium stearate is 0.2%; the thickness of the lower layer is 1 μm, and the content of binary copolymerized polypropylene is 99.2%. Methyl diacrylate 0.6%, sodium stearate 0.2%.

[0034] Film making: The degradable biaxially stretched polypropylene cigarette film packaging film of the present invention is produced by using a biaxially stretched co-extrusion process, wherein the temperature of the extruder: 230°C; the temperature of the casting machine: 20°C; the longitudinal stretch ratio: 520 %, longitudinal stretching p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Longitudinal stretching preheating temperature | aaaaa | aaaaa |

| Longitudinal stretch temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com