Injection mould for curved needle clamp

A technology of injection molds and loopers, applied in the field of injection molds, can solve problems such as demoulding failure, affecting production efficiency, increasing cost burden, etc., and achieves the effects of faster inflow, easy operation, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

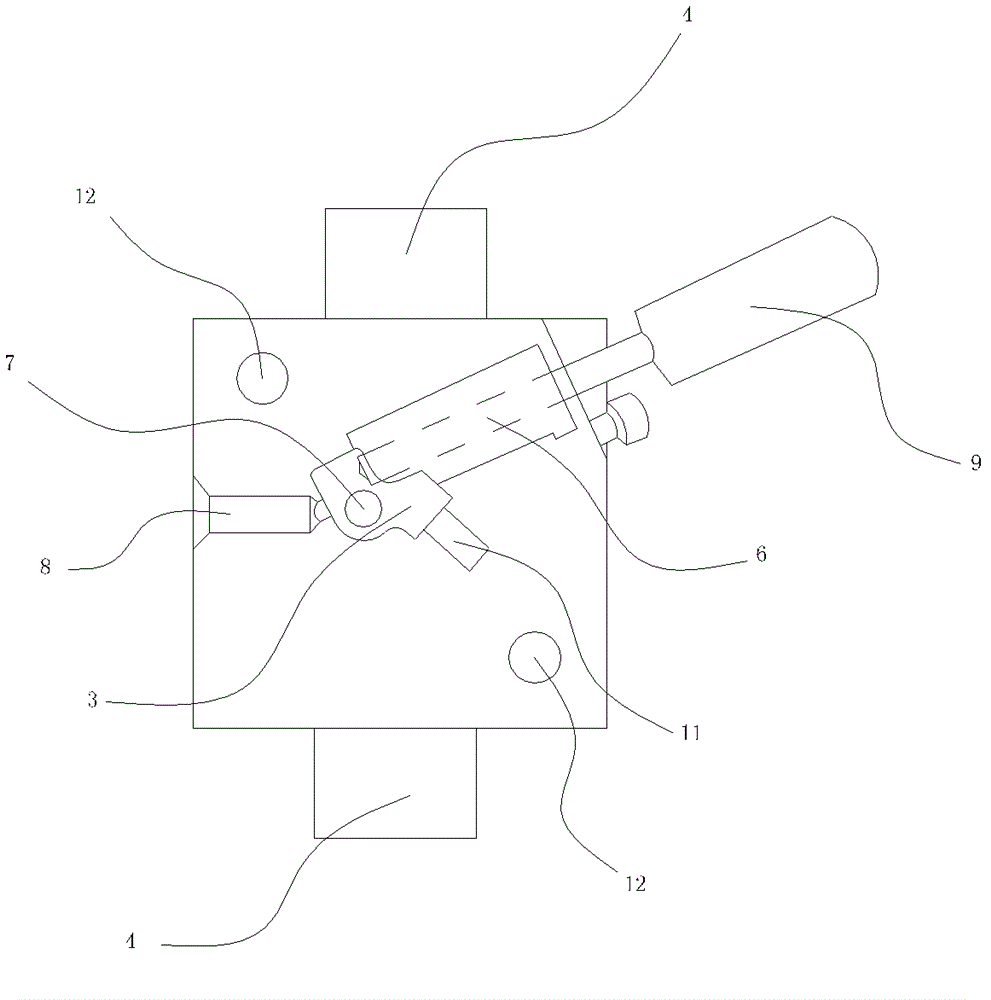

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. see Figure 1-4 The illustrated embodiment schematically reflects the installation and application structure diagram of the injection mold of the looper clip implemented according to the present invention, and shows the basic principle of the present invention.

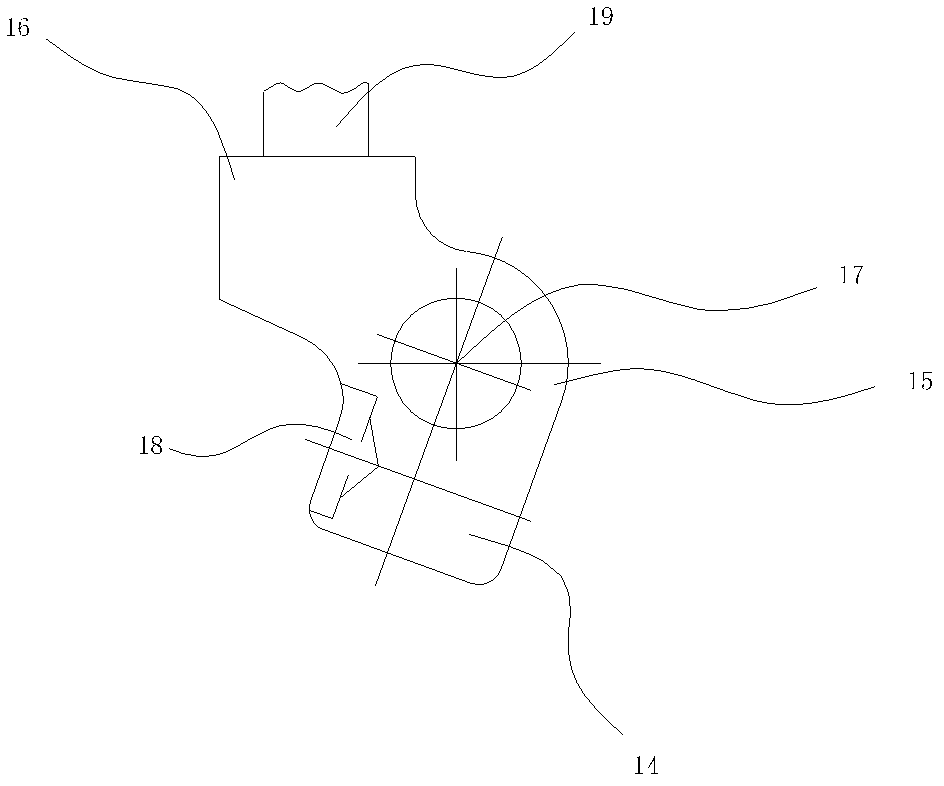

[0019] figure 1 Shows the front view of the looper clip, one end of the first connecting head 14 is connected to one end of the connecting arm 15, the other end of the connecting arm 15 is connected to the second connecting head 16, and the side of the first connecting head 16 is provided with a positioning The cavity 18, the connecting arm 15 has a through hole 17 passing through itself in the transverse direction, and the end surface of the second connecting head 15 is also connected with a protrusion 19.

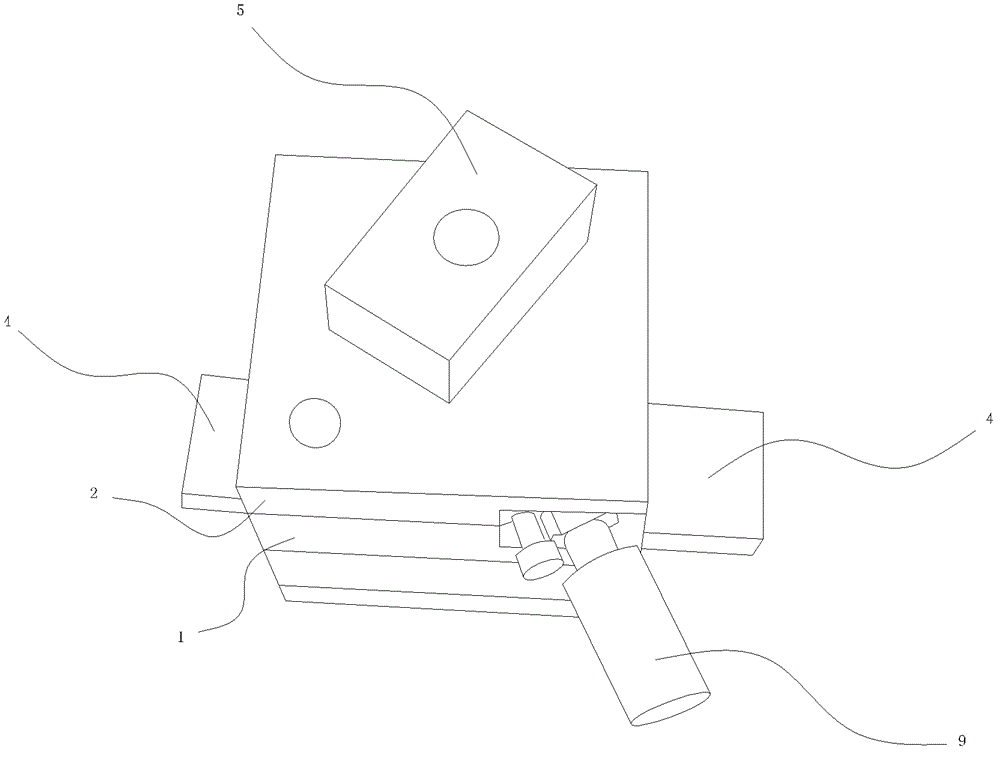

[0020] figure 2 It shows the schematic diagram of the external structure i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com