System and method for processing micro conical bore by rotation of laser beam

A conical hole and rotary processing technology, applied in the laser field, can solve the problems of low reliability and difficult to control precision, and achieve the effect of high precision, high roughness and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

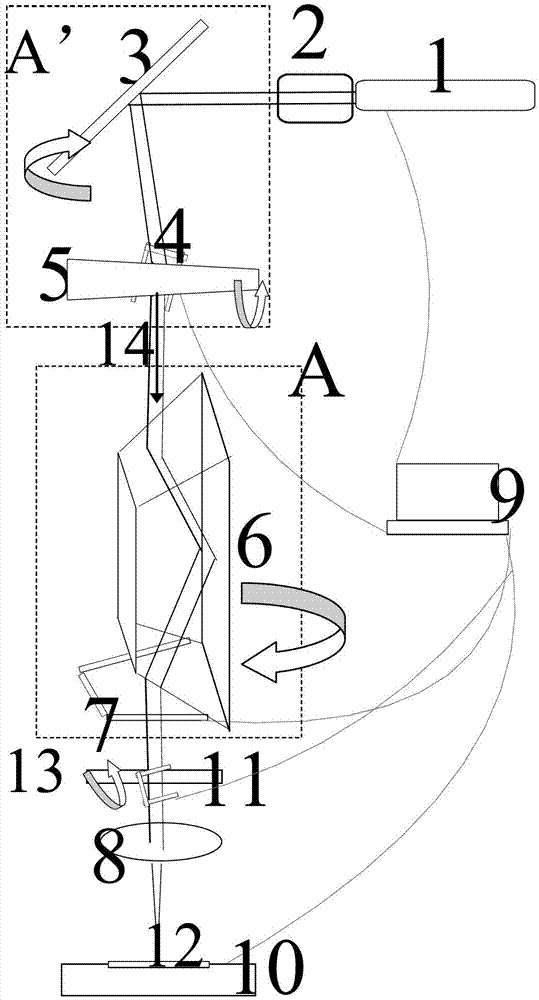

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

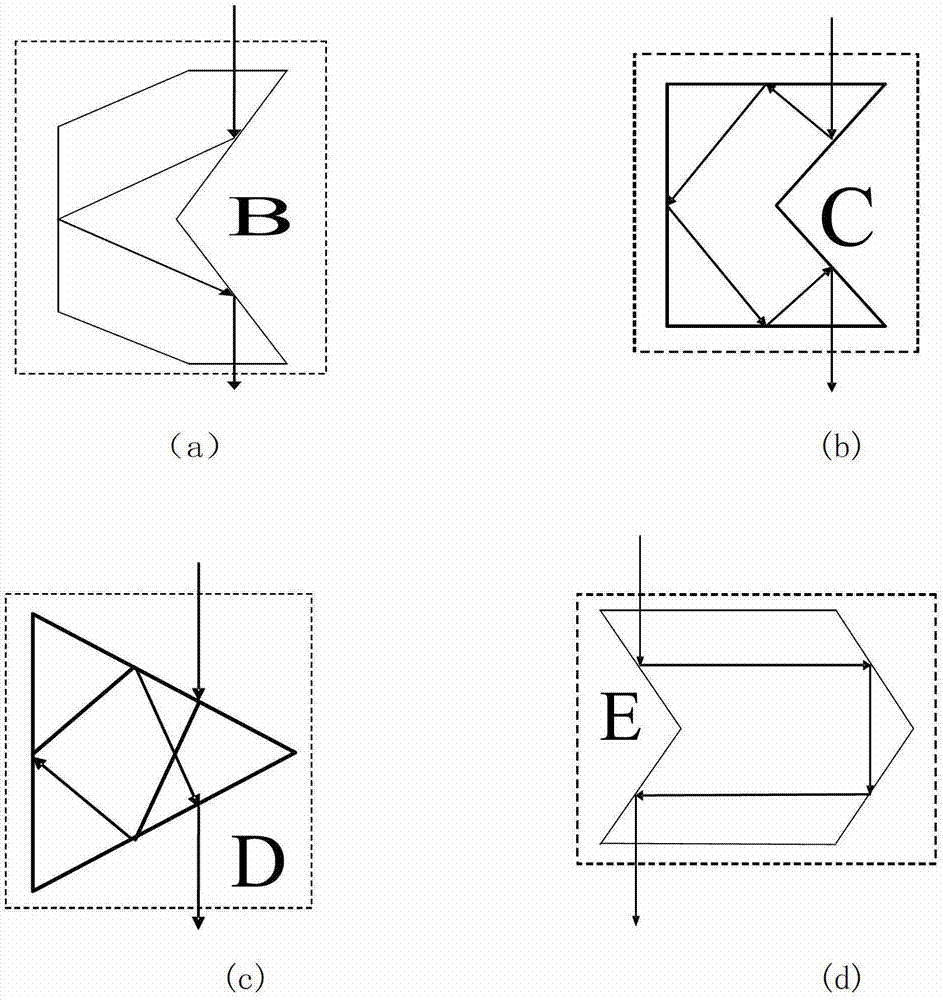

[0029] The system of the laser beam rotation processing tiny conical hole proposed by the present invention comprises: a laser generating unit, a laser deflection unit, a laser rotation unit, a taper control unit and a laser processing unit; At the incident end of the unit, the laser deflection unit deflects the short pulse laser and sends it to the incident end of the laser rotation unit from its output end; The control unit corrects the horizontal distance between the laser beam and the optical axis, and then the laser beam shoots from the exit end of the taper control unit to the workpiece to be processed on the laser processing unit. The following introduces in detail each unit that forms the system of the present invention:

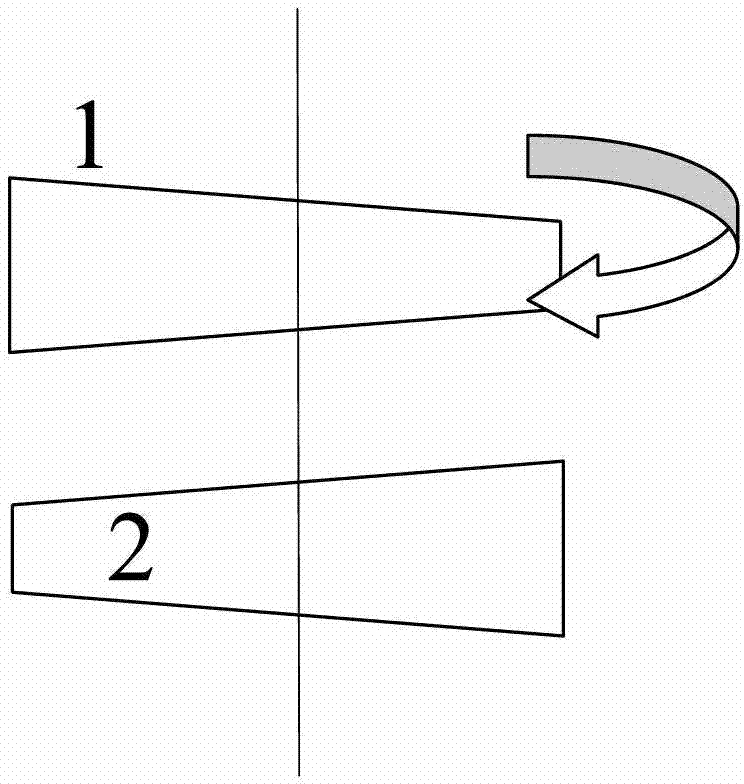

[0030] laser generating unit

[0031] The laser generating unit is used to generate a beam of ultrashort pulse laser, which includes an ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com