Laser joint cutting device with adjustable machining size and controllable taper

A size processing and laser cutting technology, which is applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of difficult integration, high cost, and complex processing, and achieve the effect of convenient operation, simple structure, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

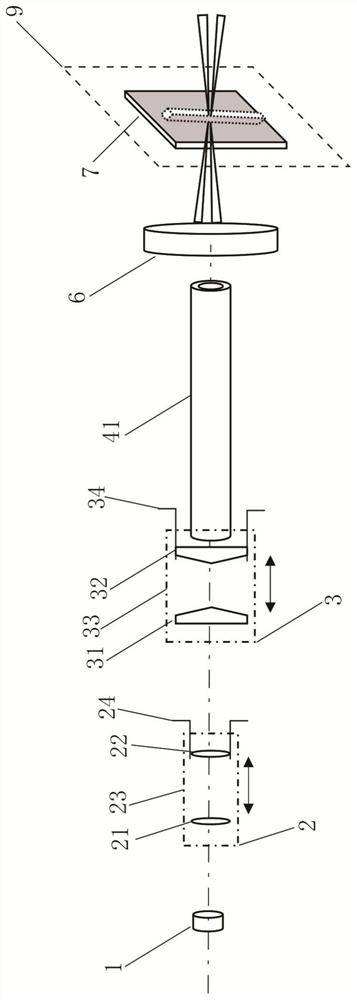

[0046] refer to figure 1 , using the structure of the quarter wave plate 1 of the present invention, the divergence angle regulator 2, the axicon lens pair 3, the focusing lens 6 and the workbench 9 to cut a rectangular groove on the workpiece 7;

[0047] The laser wavelength range of the selected laser is 100nm-12um; the pulse width range is 50fs-100ms;

[0048] The first step: install the workpiece 7 on the workbench 9;

[0049] The second step: adjust the divergence angle adjuster 2 according to the width of the workpiece 7 to be cut;

[0050] Step 3: Adjust the axicon lens pair 3 to the initial position, and the laser focal point passes through the focusing lens 6 in turn according to the set path, and acts on the upper surface of the workpiece 7 on the workbench 9;

[0051] Step 4: adjust the divergence angle regulator adjusting ring 24 of the divergence angle regulator 2, and adjust the divergence angle by changing the position of the concave lens 21 and the convex len...

Embodiment 2

[0054] refer to figure 1 , adopt the structure of the quarter-wave plate 1 of the present invention, the divergence angle regulator 2, the axicon lens pair 3, the focusing lens 6 and the workbench 9 to cut a tapered groove on the workpiece 7;

[0055] The laser wavelength range of the selected laser is 100nm-12um; the pulse width range is 50fs-100ms;

[0056] The first step: the workpiece 7 is installed on the workbench 9;

[0057] The second step: adjust the divergence angle adjuster 2 according to the width of the workpiece 7 to be cut;

[0058] Step 3: Adjust the axicon lens pair 3 to the initial position, and the laser focal point passes through the focusing lens 6 in turn according to the set path, and acts on the upper surface of the workpiece 7 on the workbench 9;

[0059] The fourth step: adjust the taper and adjust the axicon pair of 3 axicons to adjust the ring 34, by controlling the distance between the first axicon 31 and the second axicon 32, to control the proc...

Embodiment 3

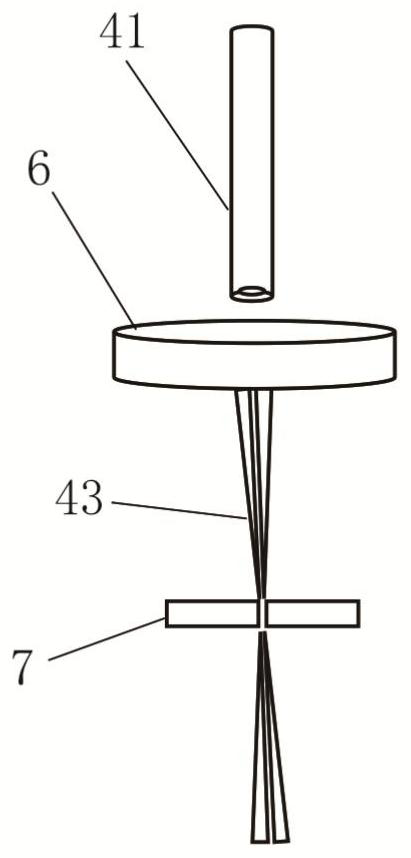

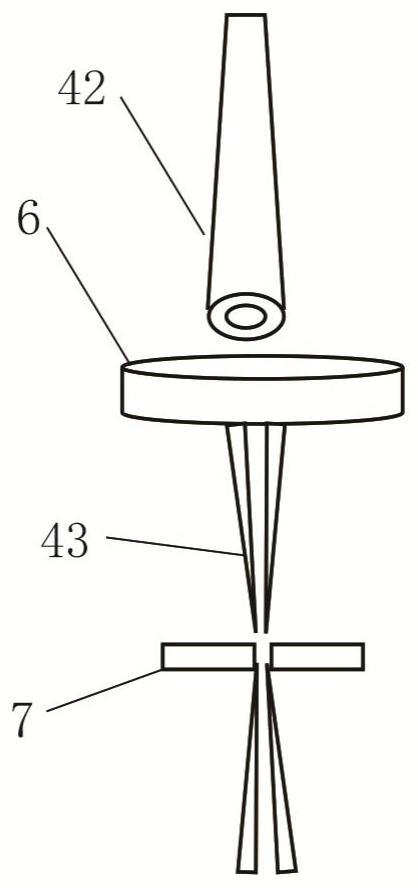

[0062] refer to Figure 6 , adopt the structure of quarter-wave plate 1 of the present invention, divergence angle regulator 2, axicon lens pair 3, mirror 4, focusing lens 6 and workbench 9 to cut tapered groove on workpiece 7;

[0063] Since the reflector 4 is set in the optical path, the laser beam is reflected from horizontal to vertical, and the laser wavelength range of the selected laser is 100nm-12um; the pulse width range is 50fs-100ms;

[0064] The first step: install the workpiece 7 on the workbench 9;

[0065] The second step: adjust the divergence angle adjuster 2 according to the width of the workpiece 7 to be cut;

[0066] Step 3: Adjust the axicon lens pair 3 to the initial position, and the laser focal point passes through the focusing lens 6 in turn according to the set path, and acts on the upper surface of the workpiece 7 on the workbench 9;

[0067] Step 4: adjust the divergence angle regulator adjusting ring 24 of the divergence angle regulator 2, and ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com