Secondary lifting device for powder concentrator

The technology of a lifting device and a powder separator is applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., which can solve the problems of reducing the efficiency of pulverizers, and achieve balance and avoid efficiency. Reduce and improve the effect of powder selection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

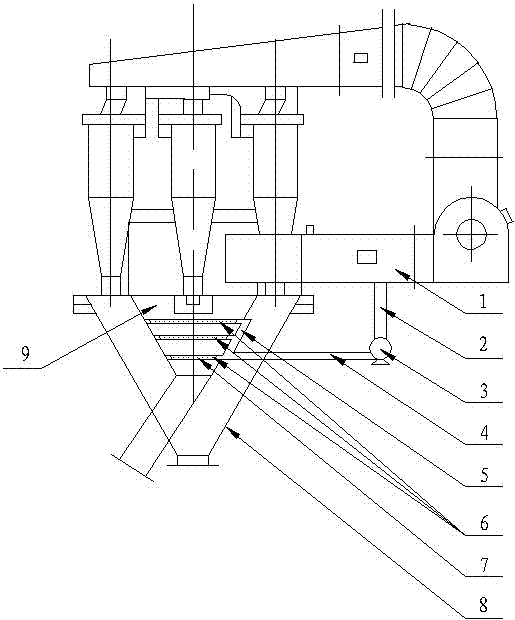

[0012] figure 1 Among them, a secondary lifting device of a powder classifier is composed of a booster fan inlet duct 2, a booster fan 3, a booster fan outlet duct 4, a connecting duct 5 and an annular duct 6. The booster fan 3 is located outside the powder separator. The booster fan 3 is provided with a booster fan inlet pipe 2 and a booster fan outlet pipe 4. The booster fan inlet pipe 2 is connected to the main fan outlet pipe of the powder separator. 1, the booster fan outlet pipe 4 passes through the conical shell 8 of the powder classifier and extends to the outside of the coarse powder cone 9 of the powder classifier, and the coarse powder cone 9 is provided with three-layer annular air ducts 6 at intervals horizontally, and the booster fan The air outlet pipe 4 is connected to the three-layer annular air pipe 6 through the connecting air pipe 5 , and the annular air pipe 6 is provided with a nozzle 7 . The outer ring wall of the annular air duct 6 is close to the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com