Reactor with functions of reaction product separation and disturbance increase

A technology of reaction products and disturbance functions, applied in chemical instruments and methods, chemical/physical processes, carbon dioxide or inorganic carbonate preparation, etc., can solve the problem of uneven concentration distribution of reactors, low conversion rate of target products, and flexible processing capacity Small problems, to achieve the effect of enhancing operational flexibility, increasing cycle disturbance, and improving conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

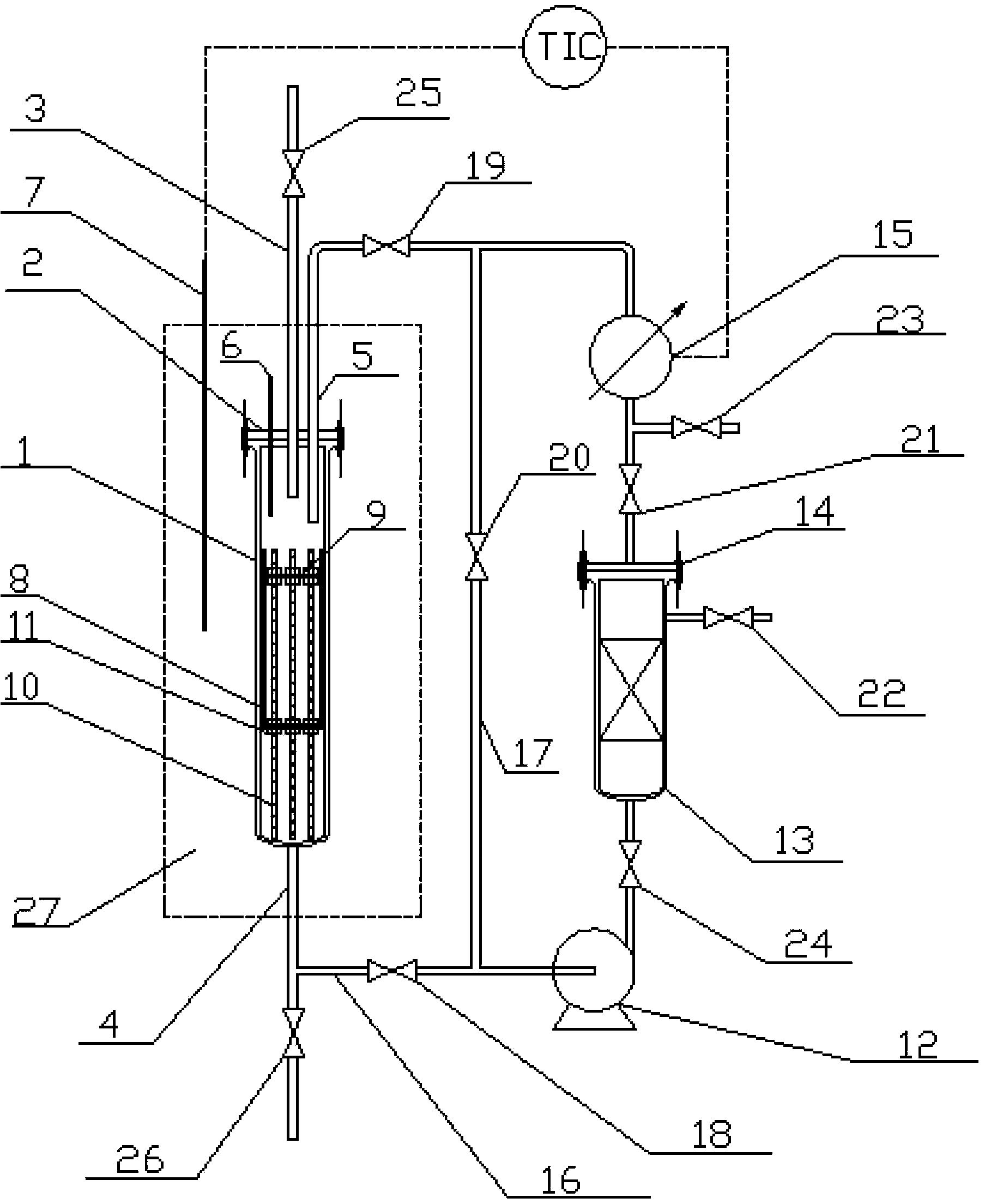

[0029] Taking the direct catalytic conversion of carbon dioxide and methanol to dimethyl carbonate as an example, the non-target product to be removed in this reaction is water. Since the partial pressure of water in this system is very low, it is not suitable to adopt the method of condensation, so the method of adsorption is used to remove water , The efficient and highly selective adsorbent used in this example is 3A molecular sieve.

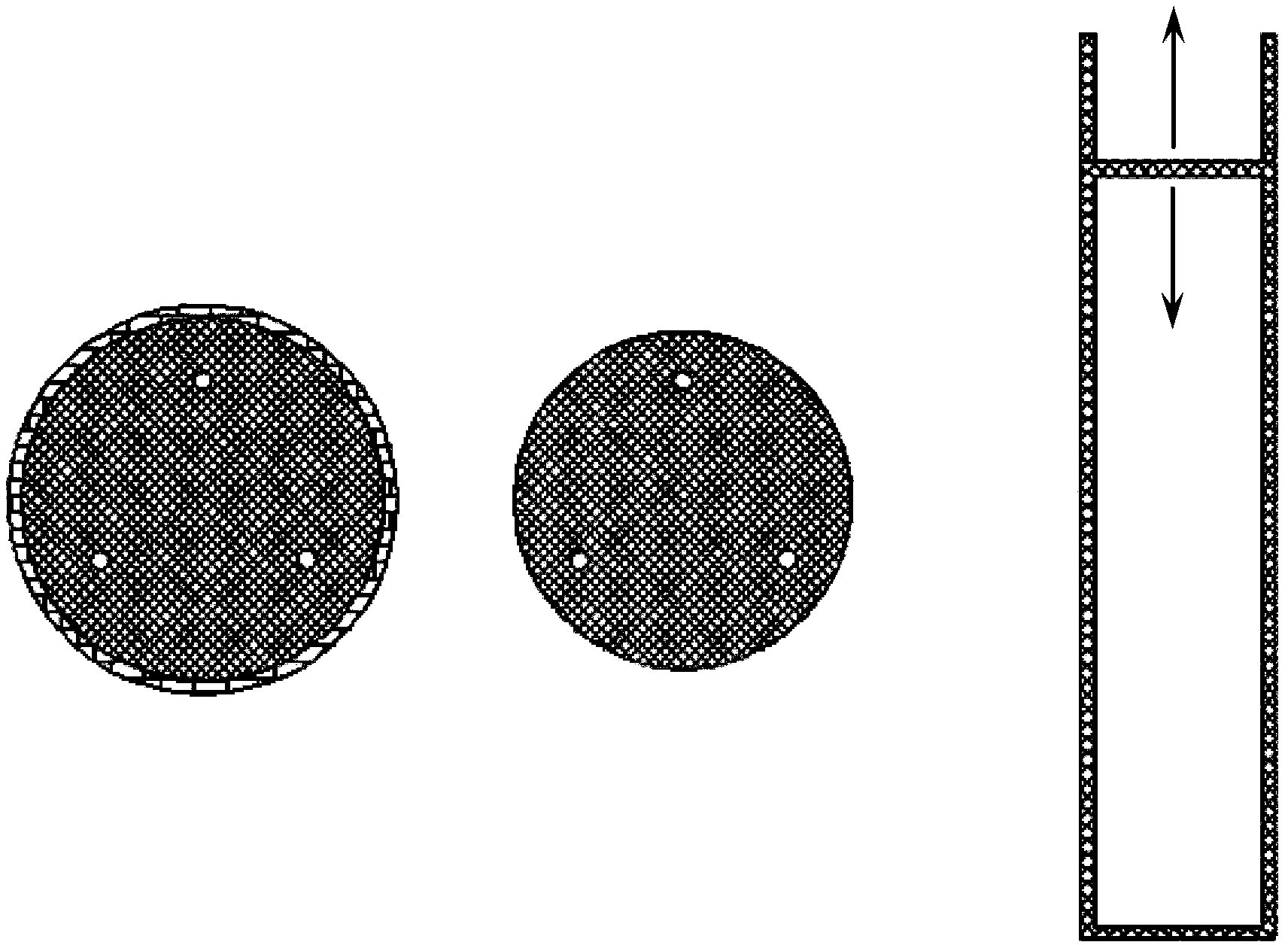

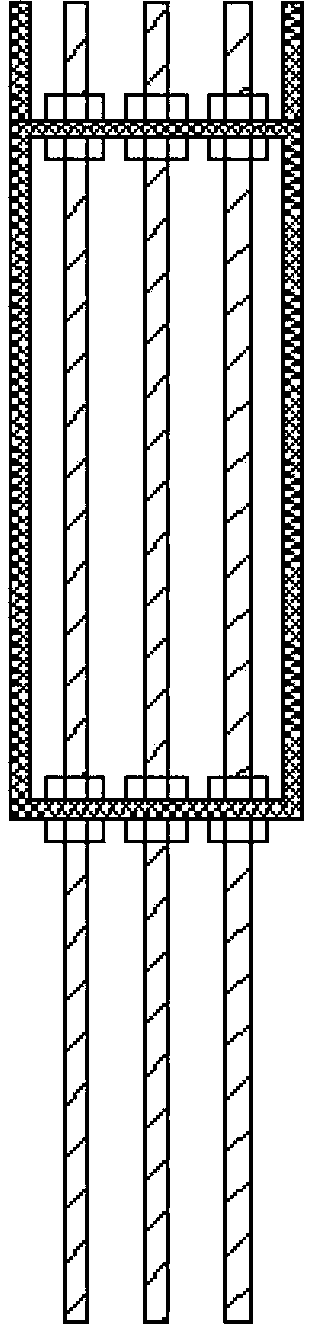

[0030] When the raw material is reacting, the bypass valve 20, the desorbent inlet valve 23, and the desorbent outlet valve 22 are closed. In this reaction, the porous support cylinder body 8 and the porous support upper cover 9 all select barbed wire for use. After reacting in the gas-phase reactor, the reactants are discharged from the gas-phase material outlet 4, diverted through the three-way, and part of them enter the reflux material inlet 16, and the reflux flow rate is controlled by the regulating valve 18. The reflux material passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com