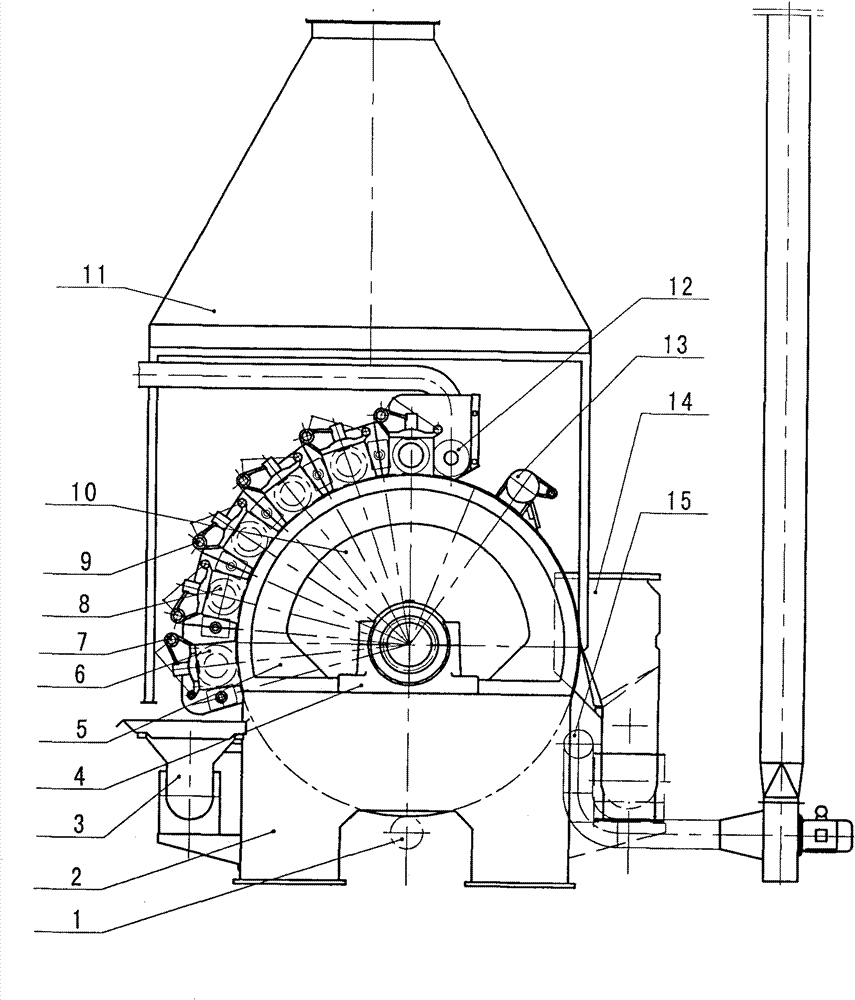

Roller dryer

A dryer and roller technology, applied in the fields of application, food preparation, food science, etc., can solve the problems affecting the quality of finished products, cannot remove stems and black spot impurities, retain the integrity of cell particles, etc., and achieve the goal of improving powder yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. Use the cloth screw device to distribute the material, so that the muddy material with low water content and poor fluidity, such as mashed potatoes, can be continuously and evenly distributed in the entire distribution tank, so that the material can be evenly coated with the first root The small roller of the cloth; prevents the material from aging in the trough and forms large hard particles, which improves the powder output rate of the product and ensures the quality of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com