Method for coating a core of an arbitrary shape by thermoforming, automatic machine for the implementation thereof and finished product obtained by such a method

A thermoforming, core piece technology, used in decorative elements, furniture and point-of-sale displays or other types of accessories, can solve problems such as unsightly joint surfaces, and achieve the effect of less harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

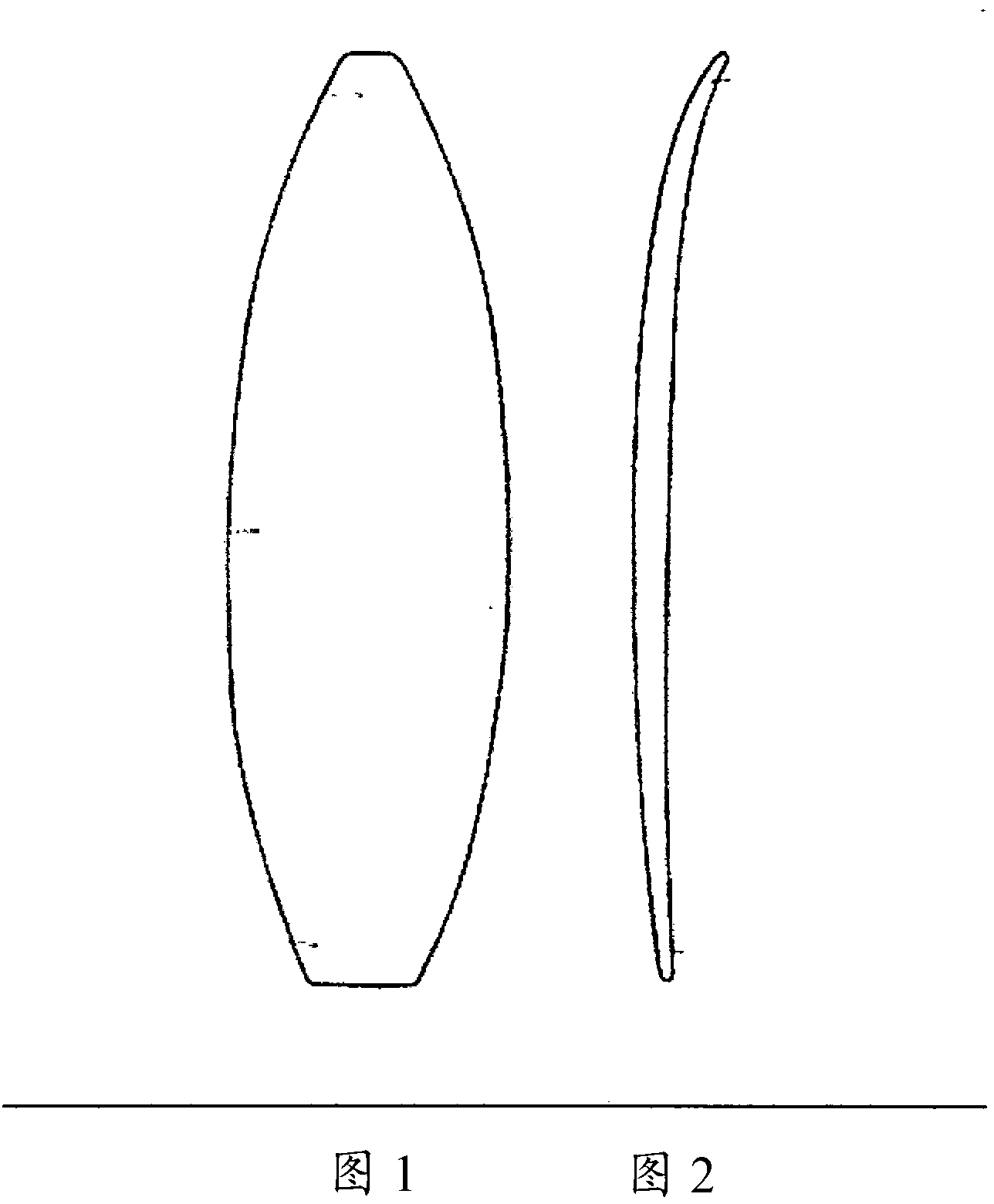

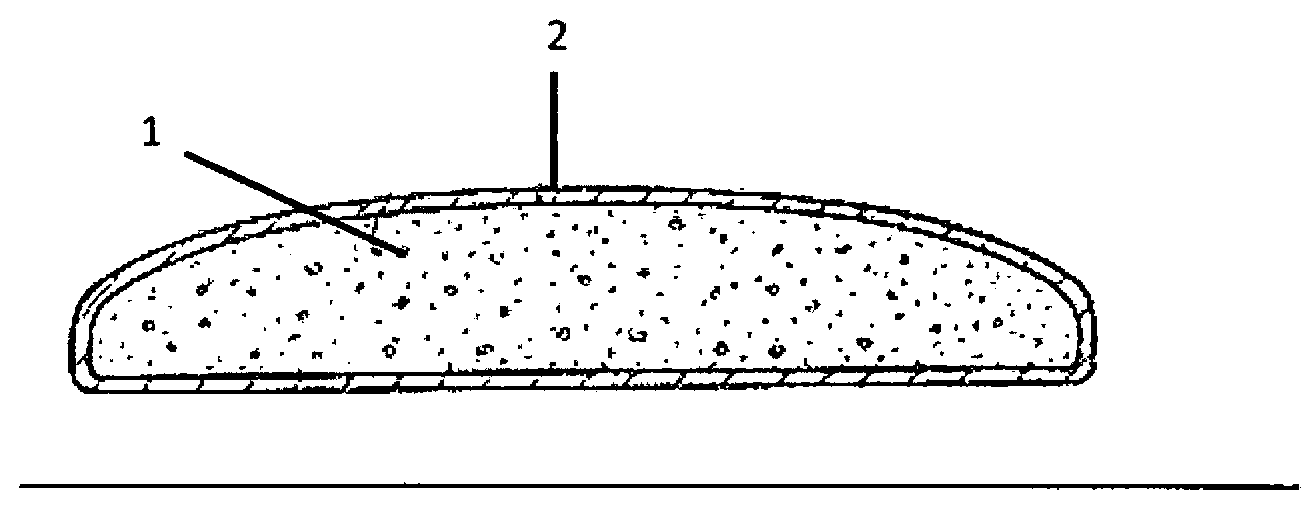

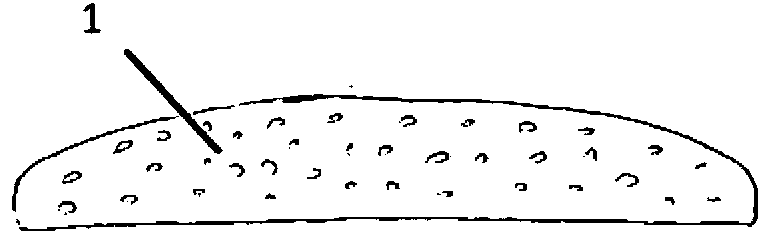

[0033] figure 1 with figure 2The conventional shapes of a watersports float are shown from above (the view is generally called "profile") and from the side (the views are usually called "foil" and "sickle curve"), respectively. In the traditional method, as in which the floaters are represented by cross-section image 3 As shown, the float is manufactured from a foam block 1 forming a preformed core covered with a layer 2 of glass fiber reinforced resin.

[0034] Foam blocks usually have a density of 50kg / m 3 polyurethane foam, but also extruded expanded polystyrene foam. The core may also have a "sandwich" structure, ie a structure formed by an assembly of layers of different kinds.

[0035] The invention described below can be applied to any type of core.

[0036] The method of the present invention for wrapping a preformed core having two faces and a lateral edge connecting the two faces involves thermoforming and direct application of a float of polymeric material in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com