Photocatalyst, slurry mixture, forming member and coating, coating film forming member, sintered body, glass-ceramic composite, glass, building material and clarification material

A technology of photocatalyst and glass ceramics, applied in the fields of photocatalyst, slurry mixture, molding material and coating, coating film forming material, sintered body, glass ceramic composite, glass, building material and purification material, can solve the problem of photocatalytic activity Volatile instability and other problems, to achieve the effect of improving photocatalytic activity, less variation, and excellent photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

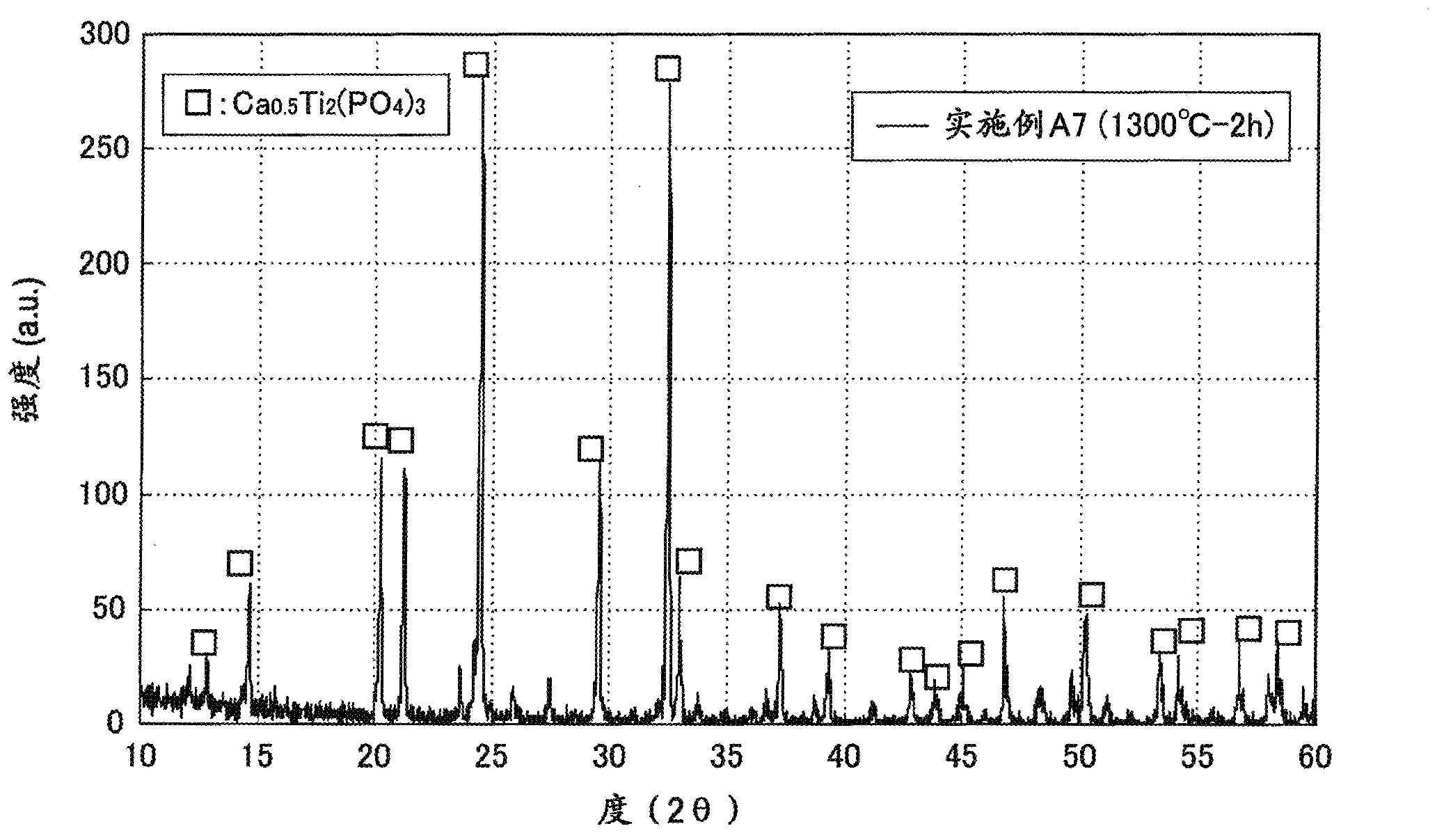

[0320] Example (No. A7)

[0321] mixed by NH 4 h 2 PO 4 、TiO 2 and Ca(PO 3 ) 2 The starting material made with NASICON-type crystallized Ca 0.5 Ti 2 (PO 4 ) 3 The stoichiometric ratio is the same, and then placed in a platinum crucible, heated at 700 °C for 16 hours and then cooled to room temperature. These were pulverized with an agate mortar, and then pulverized with a planetary ball mill to obtain a powder with an average particle diameter of 5 μm. 2 g of the powder was pressed at a pressure of 40 MPa for 2 minutes to form particles of φ20 mm, and the particles were pressed with a pressure of 2 t for 2 minutes using a cold room or other square pressure pressing (CIP) device. The obtained pellets were then heated at 1300° C. for 2 hours to obtain a bulk sintered body. As a result of analyzing the crystal structure of the obtained sintered body by the X-ray diffraction (XRD) method, the following image 3 The diffraction pattern shown. From this, it was confirme...

Embodiment B1 to Embodiment B25

[0335] Table 4 to Table 7 show glass compositions, heat treatment (crystallization) conditions, and types of main crystal phases precipitated in these glasses of Examples B1 to B25 of the present invention. The glass-ceramics of embodiment B1 to embodiment B25 are all selected as the raw material of each component respectively corresponding oxide, hydroxide, carbonate, nitrate, fluoride, chloride, metaphosphoric acid compound etc. are commonly used in glass High-purity raw materials, these raw materials are weighed and mixed uniformly to form the ratios of the compositions of each example shown in Table 4 to Table 7, and then put into a platinum crucible, and according to the melting difficulty of the glass composition, use an electric furnace at 1200 ° C Dissolve at a temperature range of 1600°C for 1 to 24 hours, stir and homogenize for rinsing, etc. The glass solution is then cast into molds and gradually cooled to make glass. The obtained glass was heated to the crystalli...

Embodiment B26 to Embodiment B57

[0357] And, make the granular sample as embodiment B26 to embodiment B57, in table 8 to table 14 represent the glass composition of embodiment B26 to embodiment B57 of the present invention, heat treatment (crystallization) condition, and precipitate in glass ceramics The type of the main crystal phase. Granular glass ceramics were produced in the following order. First, after weighing, mixing, and dissolving raw materials in the same manner as in Example B1 to Example B25 to obtain a glass melt, the glass melt was poured into water to produce glass.

[0358] Wherein, for Example B26 to Example B51, the pulverized glass was screened to form granular glass with a size of 1 to 3 mm. The glass was heat-treated under the conditions shown in Tables 8 to 12 to form glass ceramics, and then etched in a 46 wt% HF solution for 1 minute to prepare a sample for MB (methylene blue) decomposition test.

[0359] In addition, in Example B52 to Example B57, the glass ceramics obtained by pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com