Operation control device of biomass direct-combustion circulating fluidized bed boiler

A circulating fluidized bed and biomass technology, which is applied in the directions of fluidized bed combustion equipment, fuel burned in a molten state, and combustion methods, can solve problems such as difficulty in meeting the combustion control requirements of biomass direct-fired circulating fluidized bed boilers. achieve the effect of fuel control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

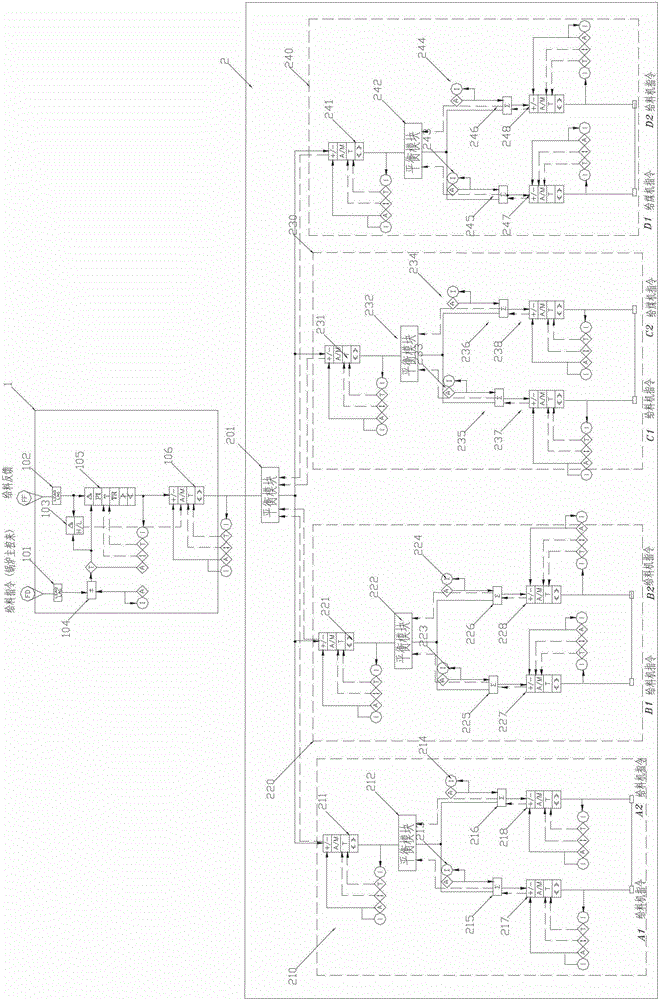

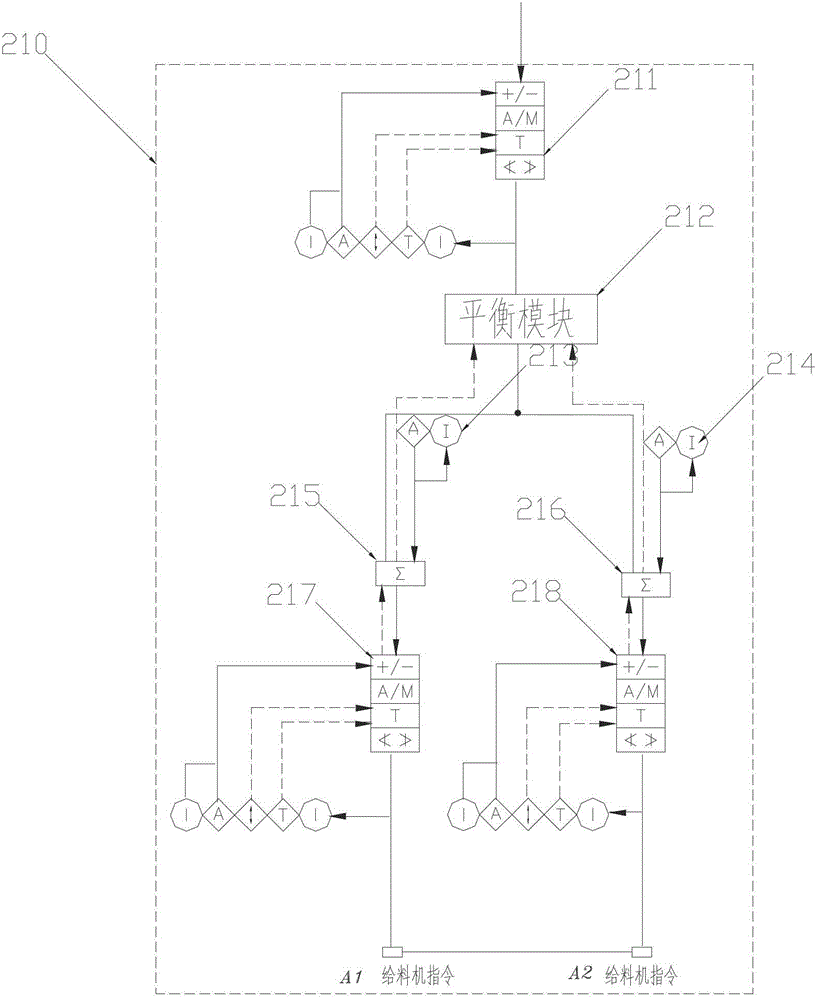

[0019] like figure 1 The illustrated embodiment of the balance feed control device for a biomass direct-fired circulating fluidized bed boiler of the present invention includes a feed main adjustment loop 1 and a feeder multi-line balance control loop 2 .

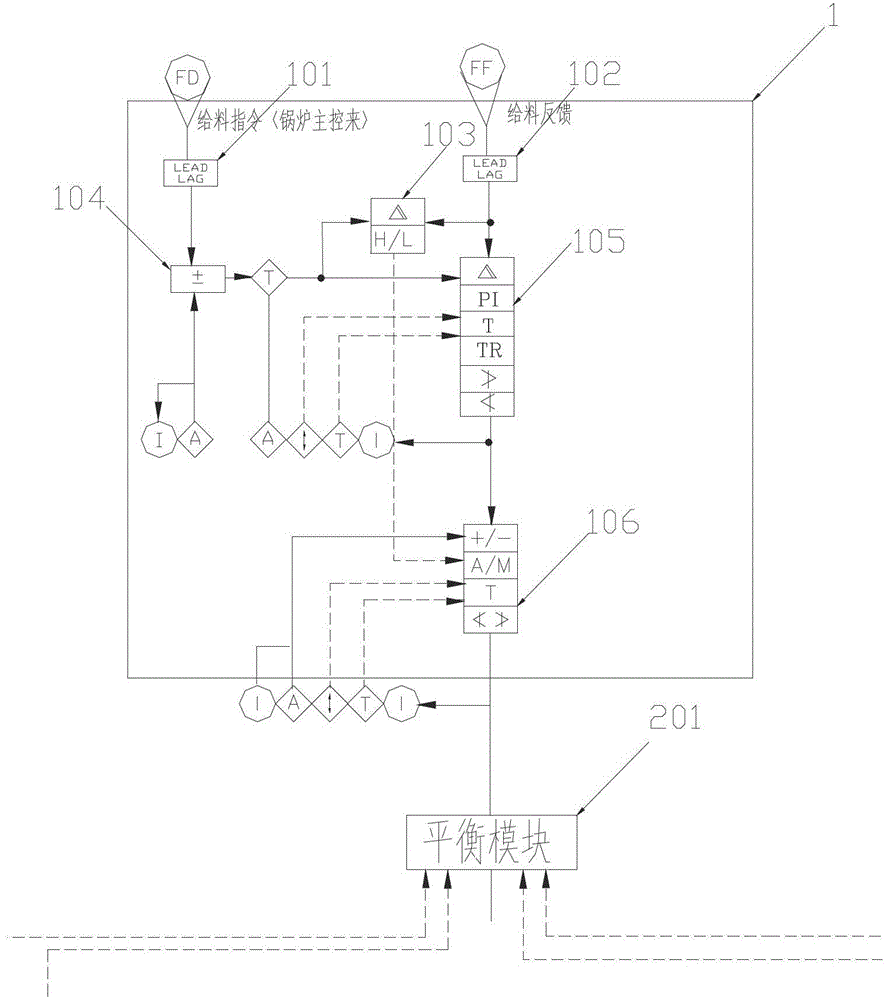

[0020] see figure 2 , the feeding main regulation loop 1 includes: the first inertial filter operation module 101, the second inertial filter operation module 102, the deviation alarm module 103, the feeding instruction correction module 104, the feeding main control PID controller 105 and the feeding main manual / auto switch module 106.

[0021] The first inertial filter operation module 101 inputs the feeding command from the main control of the boiler, and the second inertial filter operation module 102 inputs the total feed amount-feedback feedback of the actual feed amount of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com