Overhead monorail train system

A technology for monorail trains and trains, which is applied in the direction of monorail systems, motor vehicles, railway vehicles, etc. It can solve the problems affecting the construction cost, operating cost and popularization rate, the difficulty of taking into account the convenience and energy saving of trains, and the frequent starting and stopping of trains, etc., so as to achieve easy construction and Achieve commercial operation, reduce floor space and environmental impact, and achieve low vibration and noise effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

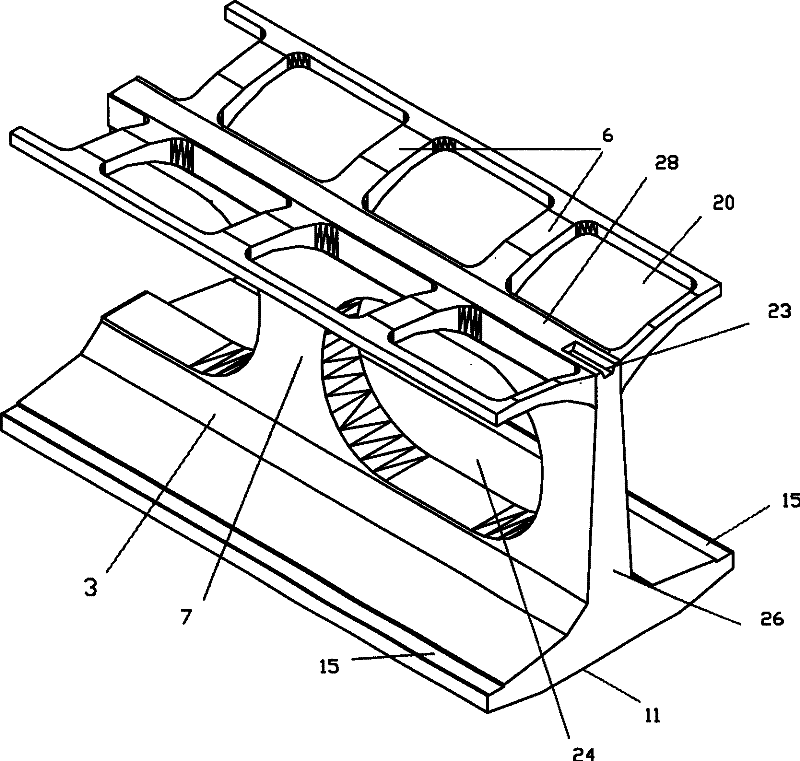

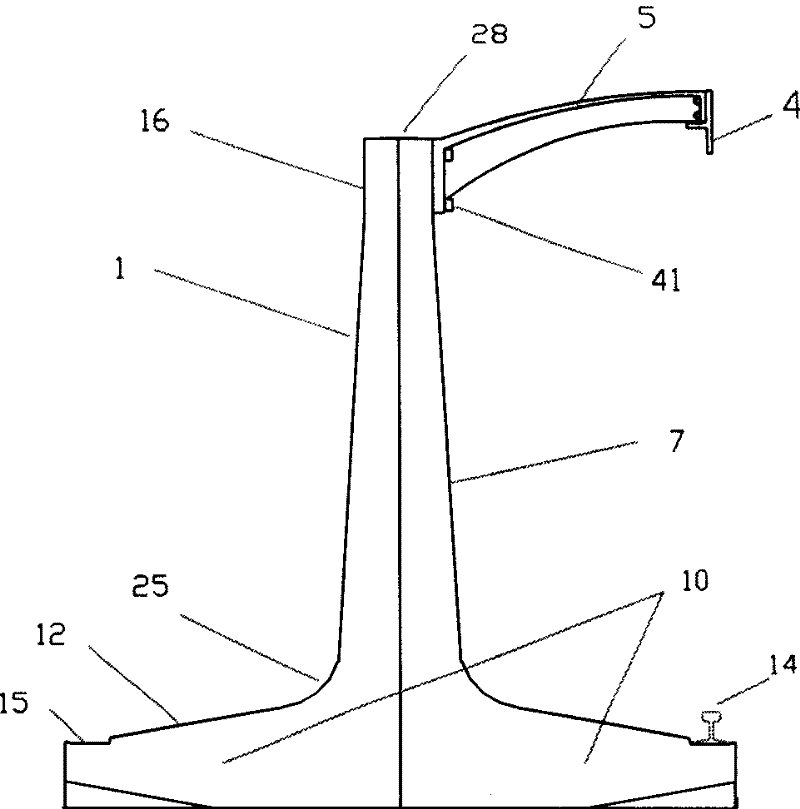

[0047] The implementation of the present invention will be further described below in conjunction with the accompanying drawings.

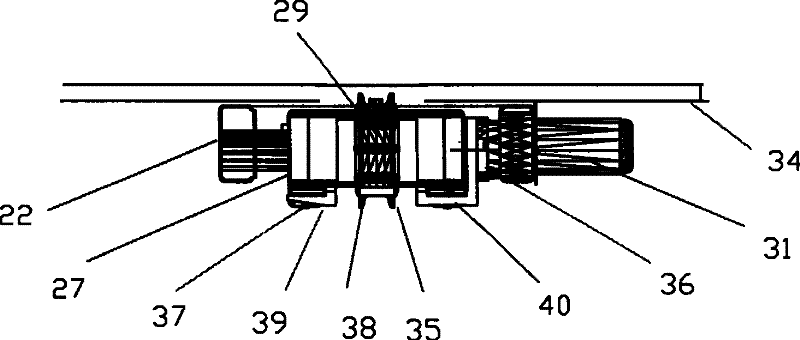

[0048] Adopt the design scheme of light-duty passenger compartment with a compartment length of 13.5 meters and a width of 2.2 meters and a compartment wall thickness of 50 mm. There are 4 passenger doors, 8 side windows and 3 ventilation windows at the top of the compartment. The balance guide frame 32 is 600 mm long and 600 mm wide. 185 mm, 6 balance guide frames 32 are installed on the top of each compartment, and there are guide rail grooves with section size (90×50) mm on the balance guide frame, the length of the buffer slider in the guide rail groove is 150 mm, and the working range of the spring element is 15 mm. mm, the diameter of the auxiliary wheel at the top of the buffer slider is 160 mm; the trapezoidal main frame 22 is made of two C-shaped steels with section dimensions (210 × 75) millimeters, and the auxiliary frame 27 is 22 ends a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com