Check type meter joint

A surface joint and non-return technology, which is applied in the field of surface joints with non-return function, can solve the problems of adding pipe connection parts, easy to cause blockage, and reducing service life, etc. long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be described clearly and completely in conjunction with the accompanying drawings in the embodiments of the present invention.

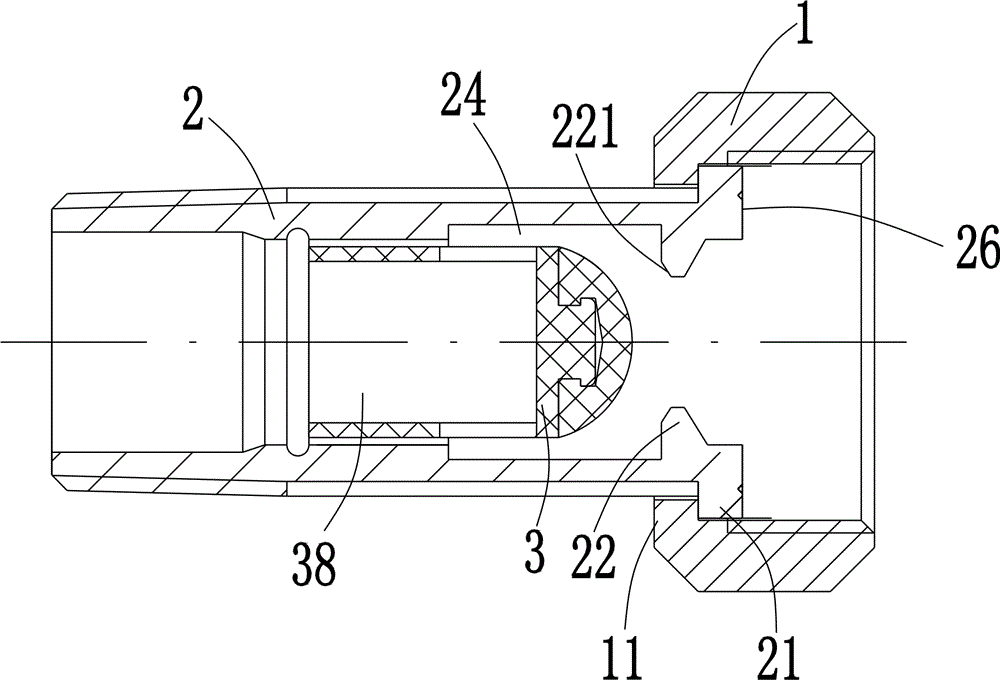

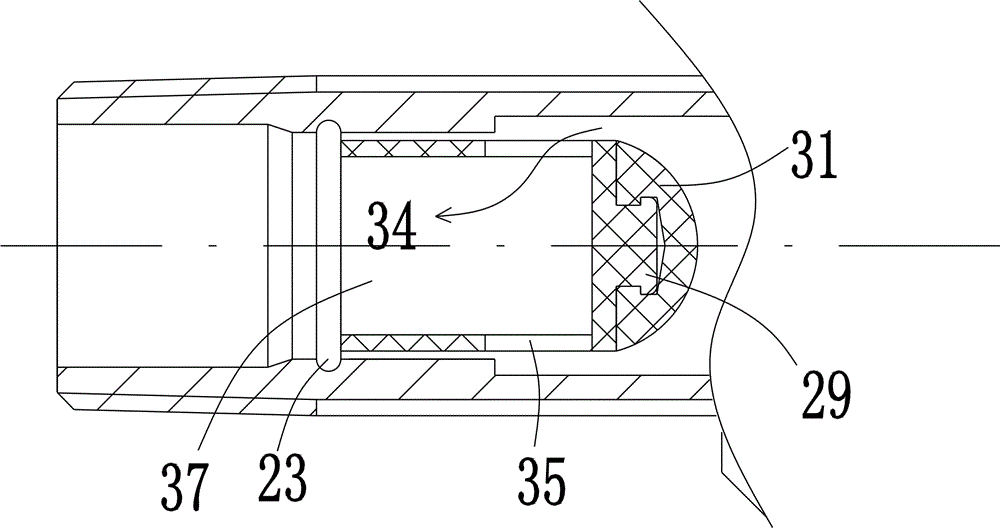

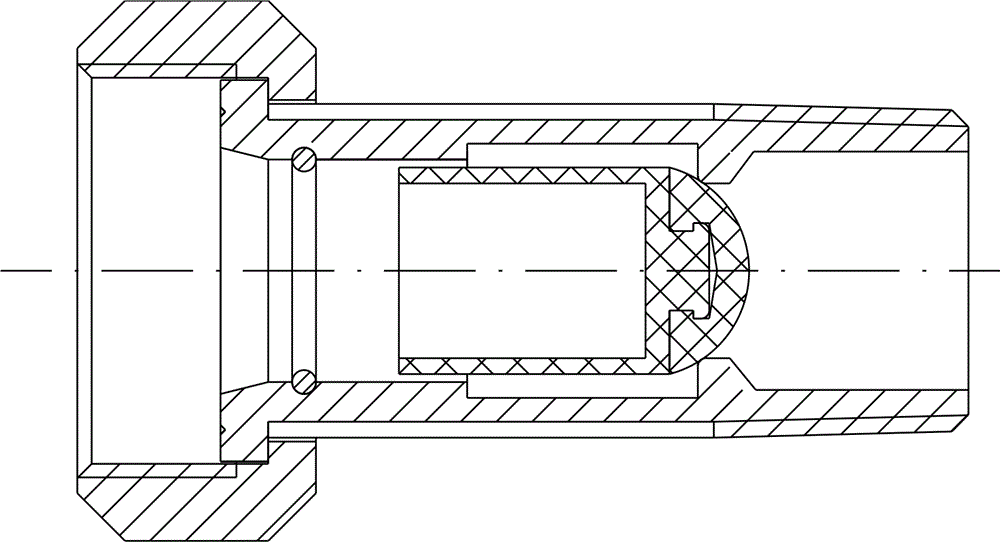

[0020] Such as figure 1 As shown, a non-return type meter connector is installed in front of the watch and includes a connector nut 1 threadedly connected to the meter and a connector tube 2 for connecting with pipe fittings. The inner end of the connector tube 2 and the connector nut 1 contact portion is provided with an annular shoulder 21. The outer end of the joint nut 1 is provided with a retaining edge 11 that is matched with the annular shoulder 21, the inner end of the connecting pipe 2 is provided with a sealing ring seat 26, and the outer end of the outer end is provided with a thread matching the pipe fitting. An inner core 3 that can move back and forth in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com