Prefabricated photoelectricity composite branch cable

A branch cable, photoelectric composite technology, applied in the direction of power cables, power cables including optical transmission elements, insulated cables, etc., can solve the problems of low construction efficiency and high cost, reduce construction costs, shorten construction periods, and reduce laying The effect of taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

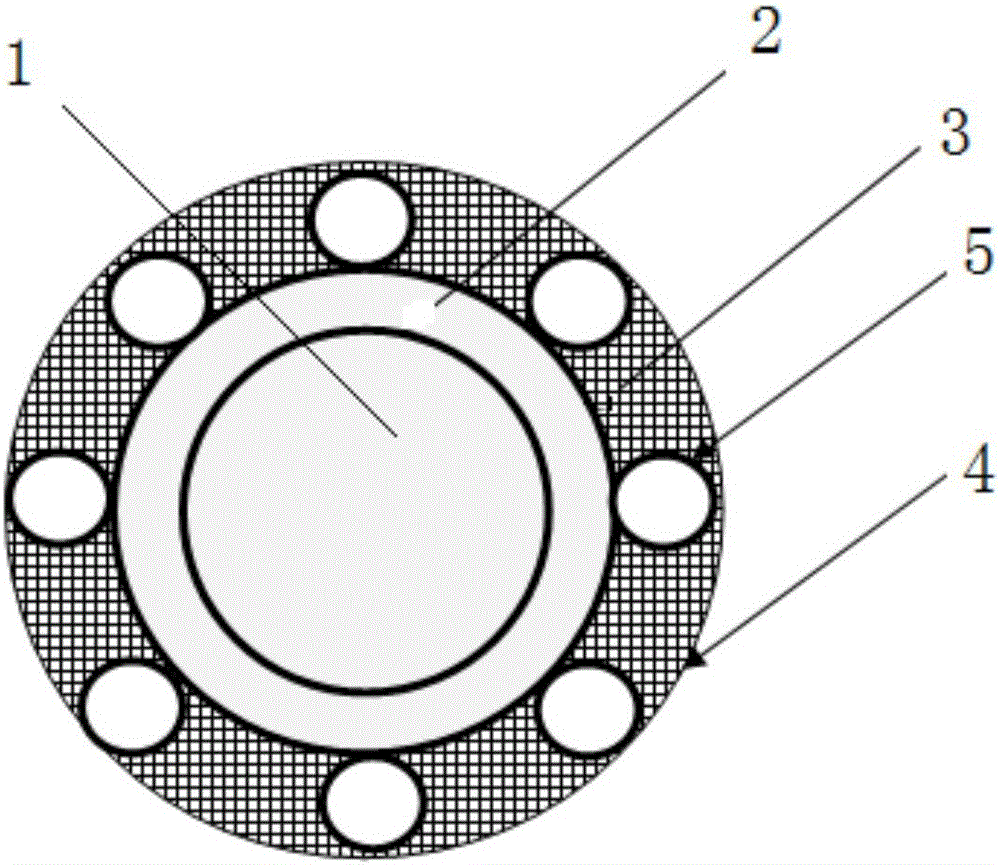

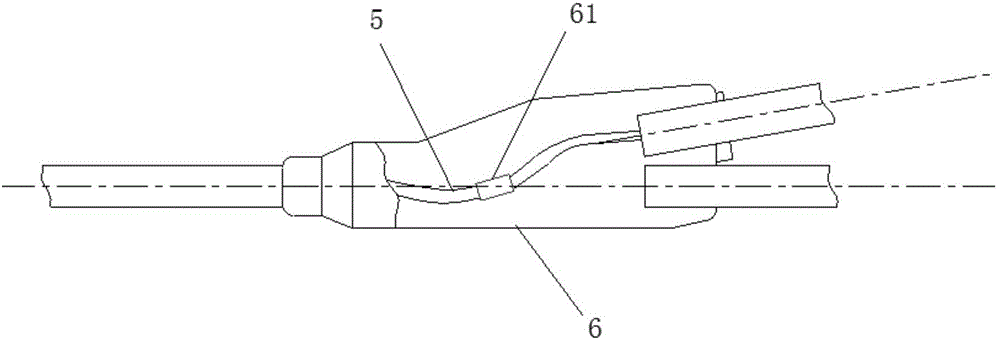

[0019] see figure 1 and figure 2 , The prefabricated photoelectric composite branch cable of the present invention includes a conductor 1, an inner insulating layer 2, an outer insulating layer 3, a sheath 4, a plurality of main optical fibers 5 and an optical fiber connector 6.

[0020] The inner insulating layer 2 covers the conductor 1 . The outer insulating layer 3 covers the inner insulating layer 2 . The sheath 4 covers the outer insulating layer 3 . Each main optical fiber 5 is compositely arranged in the outer insulating layer 3 . In this embodiment, the conductor 1 adopts the second type of conductor specified in GB / T 12706. The inner insulation layer 2 and the outer insulation layer 3 are made of cross-linked polyethylene materials that meet the requirements in GB / T 12706. The main optical fiber 5 adopts the communication optical fiber conforming to GB / T 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com