Diameter-changing and friction-reducing drill column centralizer

A centralizer and drill grinding technology, which is applied to drill pipes, drill pipes, drilling equipment, etc., can solve the problems of low centralization accuracy, difficulty in centering, limited centering effect of drill strings, etc., so as to improve drilling efficiency and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, objectives and effects of the present invention, specific embodiments of the present invention will now be described with reference to the accompanying drawings.

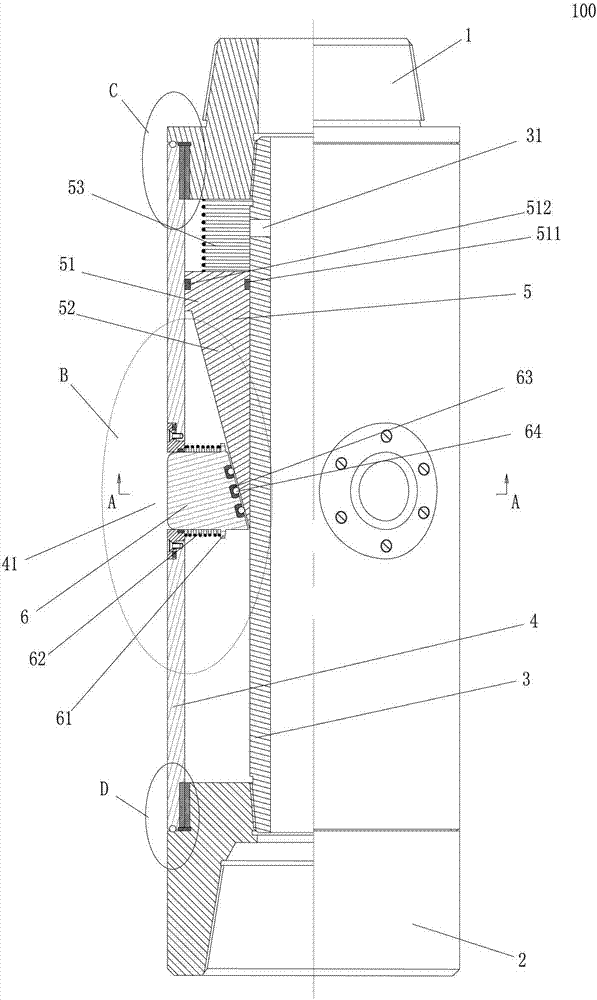

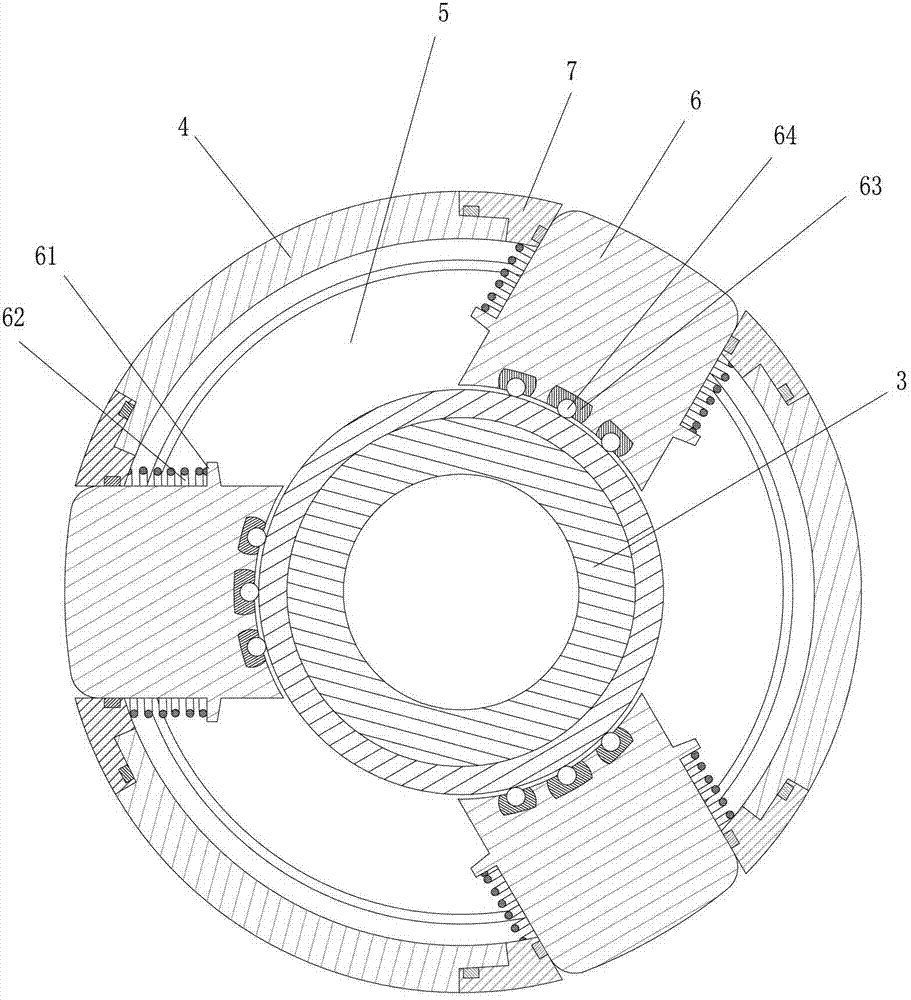

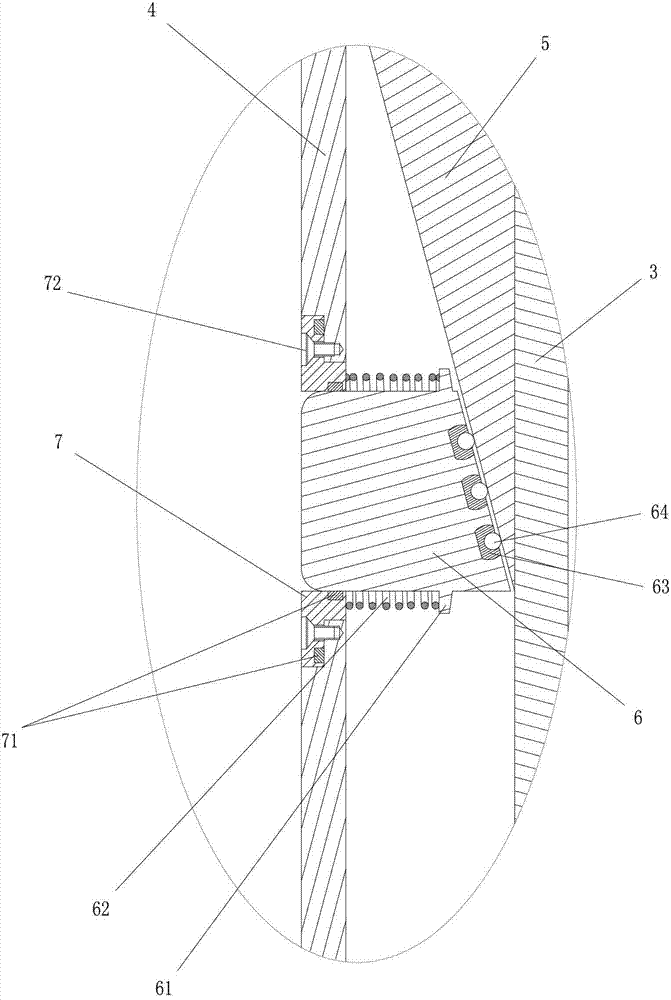

[0020] Such as Figure 1 ~ Figure 5 As shown, the present invention proposes a diameter-reducing, wear-reducing drill string centralizer 100. The centralizer 100 includes an upper joint 1, a lower joint 2, an inner pipe string 3 internally connected between the upper and lower joints, and an externally connected upper and lower joint. Between the outer pipe string 4; the inner and outer pipe strings 3, 4 form a cavity; the inner pipe string 3 and the upper and lower joints 1, 2 are fixed and sealed connections (in this embodiment, pipe thread Connection); The outer pipe column 4 and the upper and lower joints 1, 2 are sealed and rotating; the inner and outer pipe columns 3, 4 are slidingly sealed and sleeved with a cone 5, the cone 5 is made of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com