Closestool

A toilet and spray channel technology, applied in the field of sanitary ware, can solve the problems of reduced water pressure and insufficient impact force, and achieve the effects of small water pressure loss, smooth pipeline, and strong ability to pass through dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the following examples. When a person sits on the toilet as a standard, the direction of the face is the front, and the direction of the back is the back.

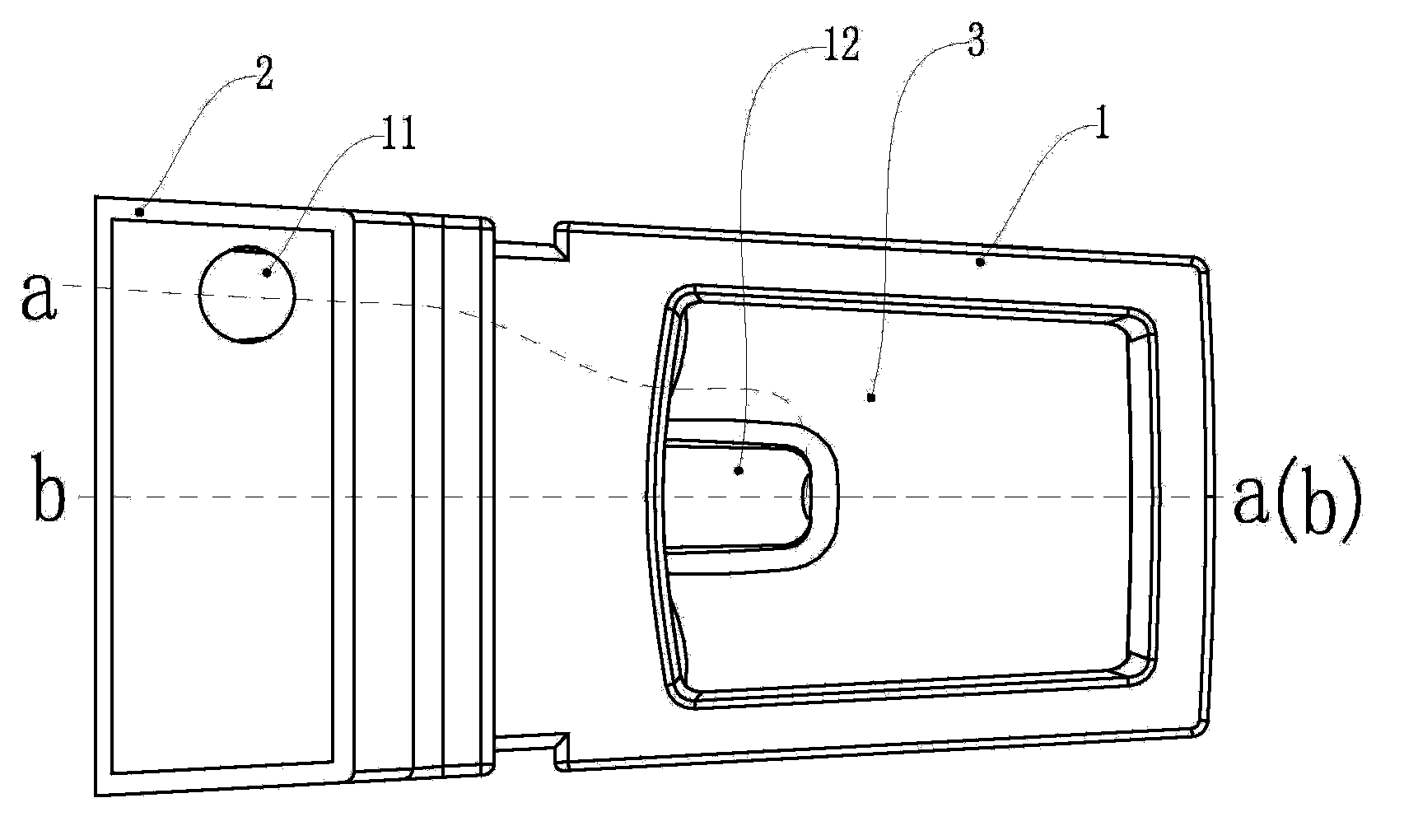

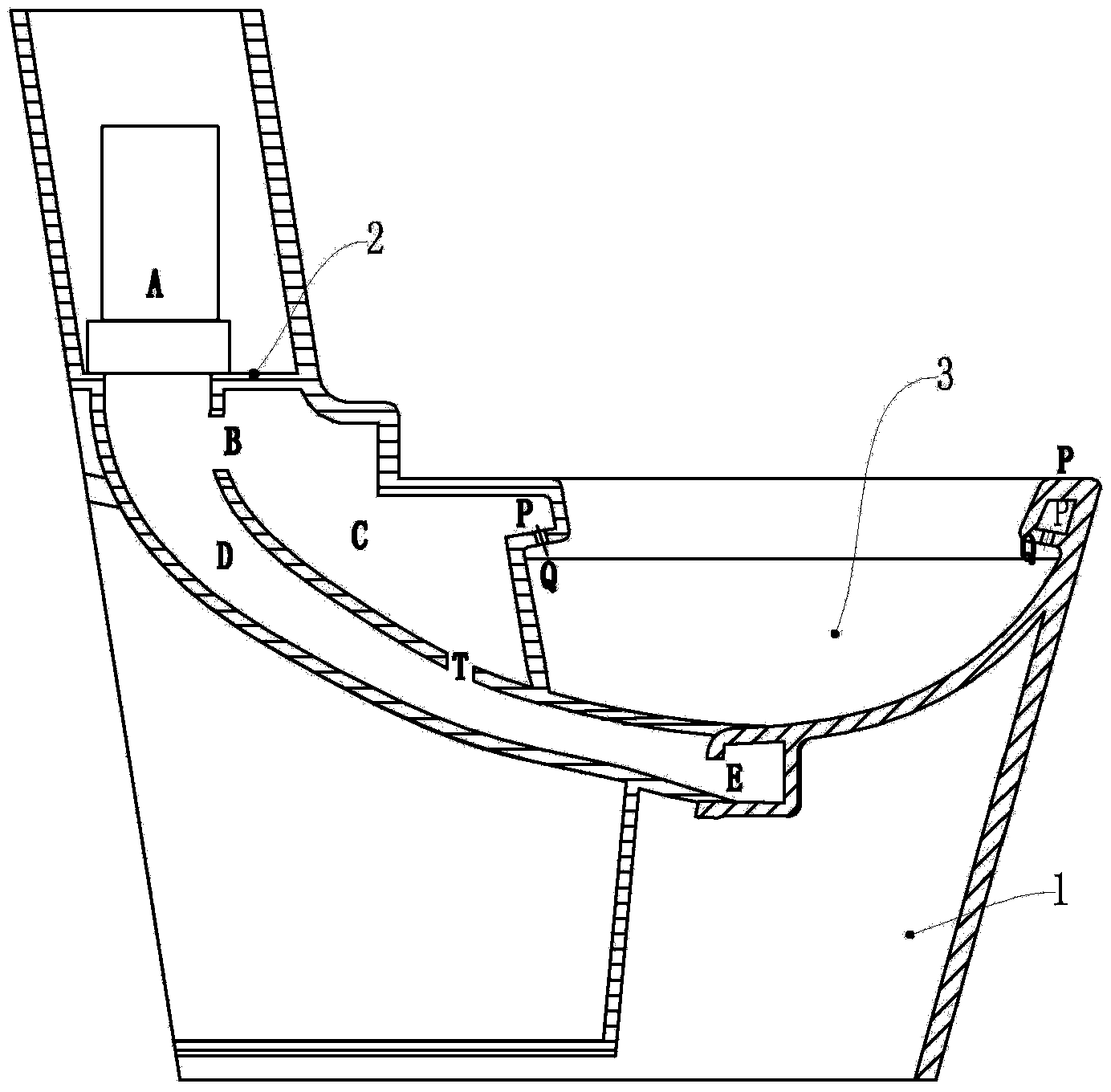

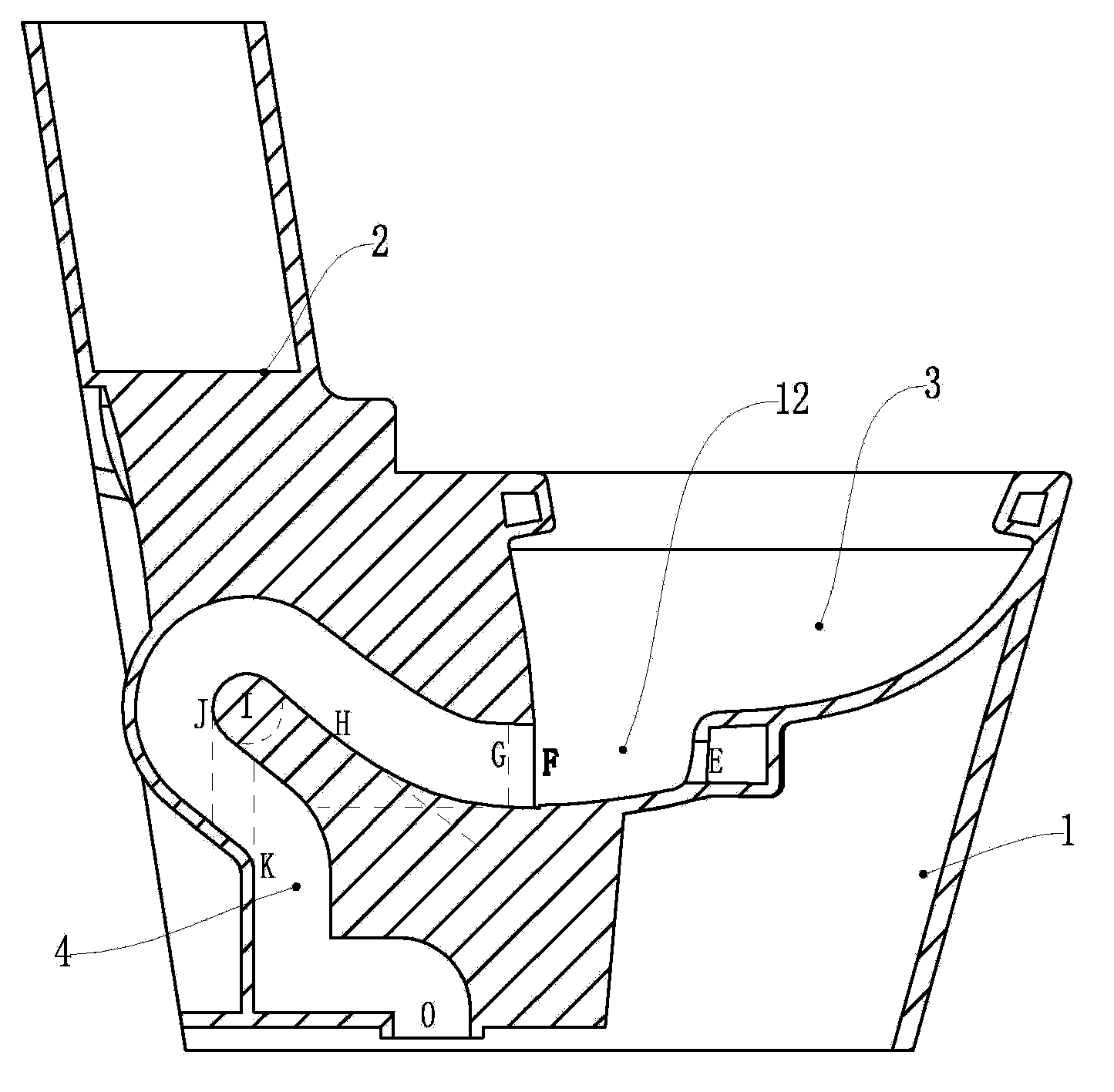

[0024] Such as figure 1 The illustrated embodiment of a toilet of the present invention includes a toilet 1, the toilet 1 is provided with a water tank connection part 2, a pool 3, a spray channel D and a siphon pipe 4, and the bottom of the pool 3 is provided with a sewage mouth 12, the inlet end of the siphon pipe 4 is connected to the sewage outlet 12, and the outlet end is connected to the outside world; the inlet end of the injection channel D is the water inlet 11, and the outlet end is the injection hole E, and the injection hole E Smaller than the cross-sectional area of the spray channel D, the water inlet hole 11 is located at the left or right position of the water tank connection part 2, the spray hole E is connected to the sewage outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com