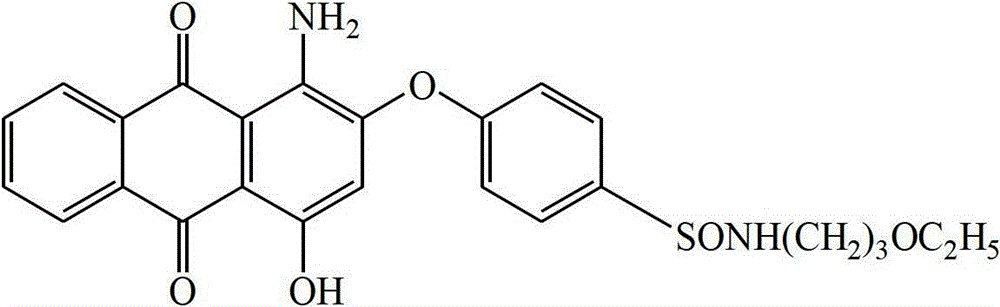

Method for preparing disperse red

A technology for disperse red and preparation steps, which is applied in the field of preparation of disperse dyes, can solve the problems of complicated process, harsh process conditions, and obstacles to the large-scale use of dispersants, and achieve the effect of simple process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

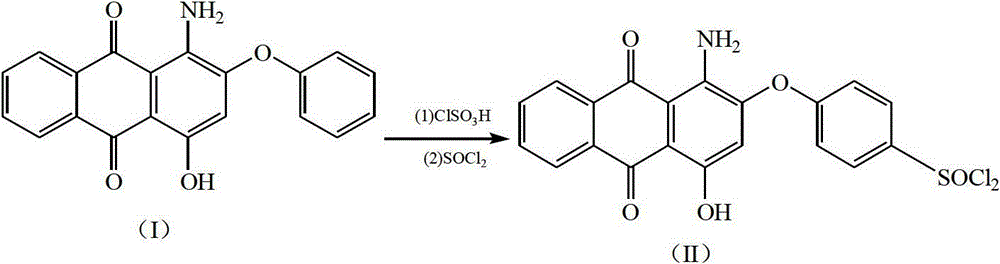

[0018] 1) Preparation of 1-amino-2-(4ˊ-chlorosulfonyl)phenoxy-4-hydroxyanthraquinone: In the reactor, add 10mol of chlorosulfonic acid, cool to 0~5℃, add 1mol of 1-Amino-2-phenoxy-4-hydroxyanthraquinone is added to the process control temperature of 0~5℃, then the temperature is increased to 42~45℃, and the reaction is stirred at this temperature for 1.5~2h. The reaction is monitored by HPLC. -Amino-2-phenoxy-4-hydroxyanthraquinone is consumed, then 1.1 mol of thionyl chloride is added, and the reaction is continued at 42~45°C for 1~1.5h. The reaction is monitored by HPLC. When the intermediate disappears, the reaction Cool the liquid to 0~5℃, then add 0~5℃ water to the reaction liquid, keep 0~5℃ and stir for 5~8min, filter, wash with water and press dry to obtain 1-amino-2-(4'-chlorosulfonate Acyl) phenoxy-4-hydroxyanthraquinone wet product;

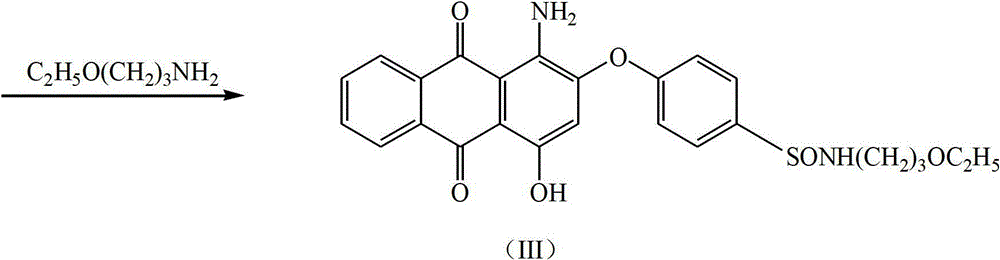

[0019] 2) Preparation of l-amino-2-[4'-(3-ethoxypropylaminosulfonyl)phenoxy]-4-hydroxyanthraquinone: add water, solvent and step 1) to t...

Embodiment 2

[0021] 1) Preparation of 1-amino-2-(4ˊ-chlorosulfonyl)phenoxy-4-hydroxyanthraquinone: Add 11.5mol of chlorosulfonic acid to the reactor, cool to 0~5℃, add 1mol under stirring The 1-amino-2-phenoxy-4-hydroxyanthraquinone was added to the process control temperature of 0~5℃, then the temperature was raised to 42~45℃, the reaction was stirred at this temperature for 1.5~2h, and the reaction was monitored by HPLC. After the consumption of 1-amino-2-phenoxy-4-hydroxyanthraquinone is complete, add 1 mol of thionyl chloride and continue the reaction at 42~45°C for 1~1.5h. HPLC monitors the reaction. When the intermediate disappears, the reaction Cool the liquid to 0~5℃, then add 0~5℃ water to the reaction liquid, keep 0~5℃ and stir for 5~8min, filter, wash with water and press dry to obtain 1-amino-2-(4'-chlorosulfonate Acyl) phenoxy-4-hydroxyanthraquinone wet product;

[0022] 2) Preparation of l-amino-2-[4'-(3-ethoxypropylaminosulfonyl)phenoxy]-4-hydroxyanthraquinone: add water, solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com