Phosphate inorganic material, method for producing same and application

A technology of inorganic materials and phosphates, applied in the field of inorganic pigment materials, can solve the problems of unfavorable discharge and grinding, low volatilization point of zinc oxide, short process flow, etc., and achieve the effects of fine particles, high weather resistance, and easy collection of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

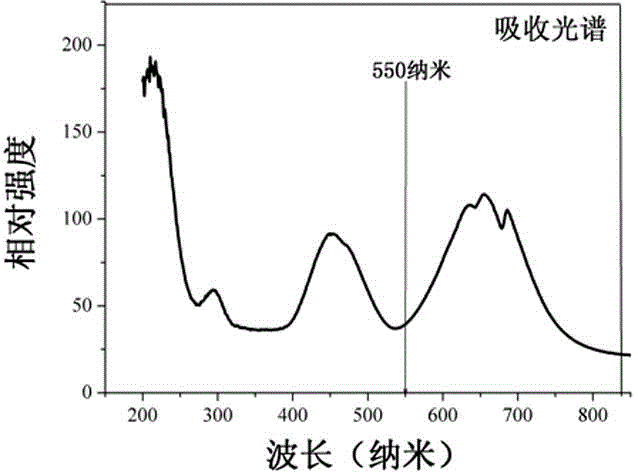

[0035] According to the chemical formula BaCr 2 (P 2 o 7 ) 2 The stoichiometric ratio of each element in , respectively weighed BaCO 3 : 1.98 g, Cr 2 o 3 : 1.52 g, NH 4 h 2 PO 4 : 4.74 g. After grinding and mixing uniformly in an agate mortar, choose the air atmosphere for the first calcination, the temperature is 300°C, and the calcination time is 5 hours, then cool to room temperature, and take out the sample. After the first calcination of the raw materials, the mixture was ground and mixed evenly, and still calcined in the air atmosphere, the calcination temperature was 1350° C., the calcination time was 7 hours, and naturally cooled to room temperature. After the sample was ground to uniformity in the same way, it was calcined at 1200° C. for 8 hours in an air-atmosphere muffle furnace to obtain the target product. Looking at a sample of the material clearly shows that the sample appears bright green to the human eye.

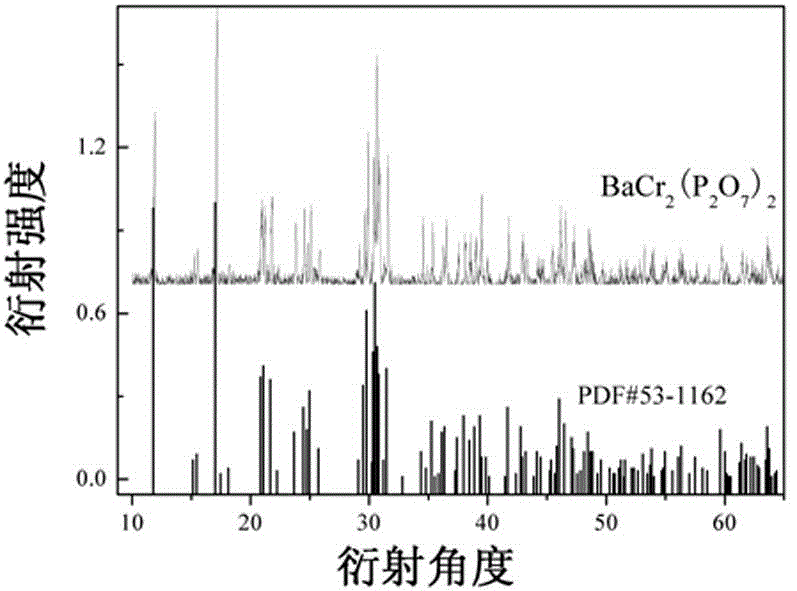

[0036] See attached figure 1 , which is ...

Embodiment 2

[0042] According to the chemical formula BaCr 2 (P 2 o 7 ) 2 The stoichiometric ratio of each element in the formula, respectively weighed BaO: 1.54 grams, Cr(NO 3 ) 3 : 4.76 g, NH 4 h 2 PO 4 : 4.74 g. After grinding and mixing uniformly in an agate mortar, choose the air atmosphere for the first calcination, the temperature is 350°C, and the calcination time is 4 hours, then cool to room temperature, and take out the sample. After the first calcined raw material, the mixture was ground and mixed uniformly, and the uniformly ground sample was calcined in an air atmosphere muffle furnace at 1300°C for 6 hours. Next, the sample cooled to room temperature was ground and calcined again in the same way. This time, the calcining temperature was 1250° C. and the calcining time was 7 hours to obtain the target product. Main structural properties, infrared spectrum and absorption spectrum are similar to Example 1.

Embodiment 3

[0044] According to the chemical formula BaCr 2 (P 2 o 7 ) 2 The stoichiometric ratio of each element in the 3 ) 2 : 2.62 g, Cr 2 o 3 : 1.52 g, P 2 o 5 : 2.84 g. After grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first calcination, the temperature is 340°C, and the calcination time is 5 hours, then cool to room temperature, and take out the sample. After the first calcined raw materials, the mixture is ground and mixed evenly, and calcined under the air atmosphere, the calcining temperature is 1350° C., and the calcining time is 6 hours. Finally, grind the sample cooled to room temperature evenly and put it into a muffle furnace for calcination. The calcination temperature is 1230° C. and the calcination time is 5 hours to obtain the target product. Main structural properties, infrared spectrum and absorption spectrum are similar to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com