Crusher

A pulverizer and chassis technology, applied in the fields of feed, grain processing, food science, etc., can solve the problems of high power consumption and large pulverized particles, and achieve the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

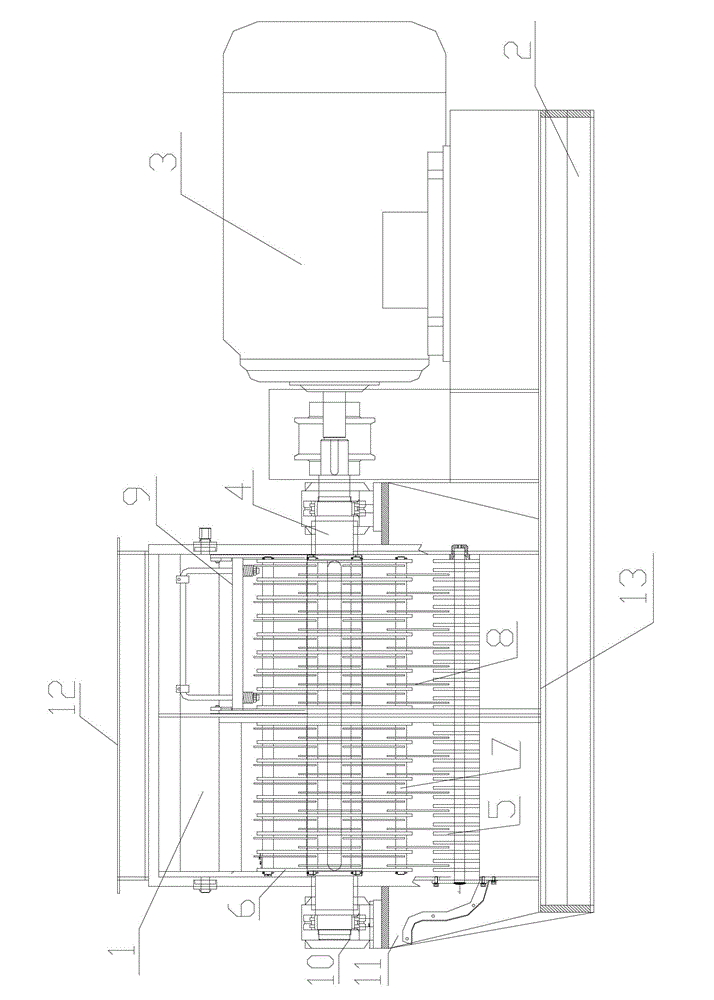

[0014] Such as figure 1 shown. A pulverizer, comprising a case 1, a base 2, a motor 3, and a main shaft 4, the case 1 and the motor 3 are fixedly arranged on the base 2, the main shaft 4 runs through the case 1, and one end of the main shaft 4 is provided There is a bearing seat 10, the other end of which is connected to the output shaft of the motor 3; a roller and a fixed knife 5 are arranged in the cabinet 1, and the roller includes an end cover 6, a hanging rod 7, and a hammer 8; The number of covers 6 is two, the end caps 6 are circular end caps, the two end caps 6 are fixed on the main shaft 4, and a hanging rod 7 is also arranged between the two end caps 6, the described The two ends of the hanging rod 7 are fixedly connected on the end cap 6, and the two ends of the hanging rod 7 are respectively fixed on the sides of the two end caps 6. The number of the hanging rods 7 is eight, and they are evenly distributed in the On the side of the end cover 6, several hammer pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com