Prediction method for corrosion resistance of laser welding plate, and system thereof

A performance prediction, laser tailor welding technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., to achieve the effect of easy operation, excellent universality and friendly interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

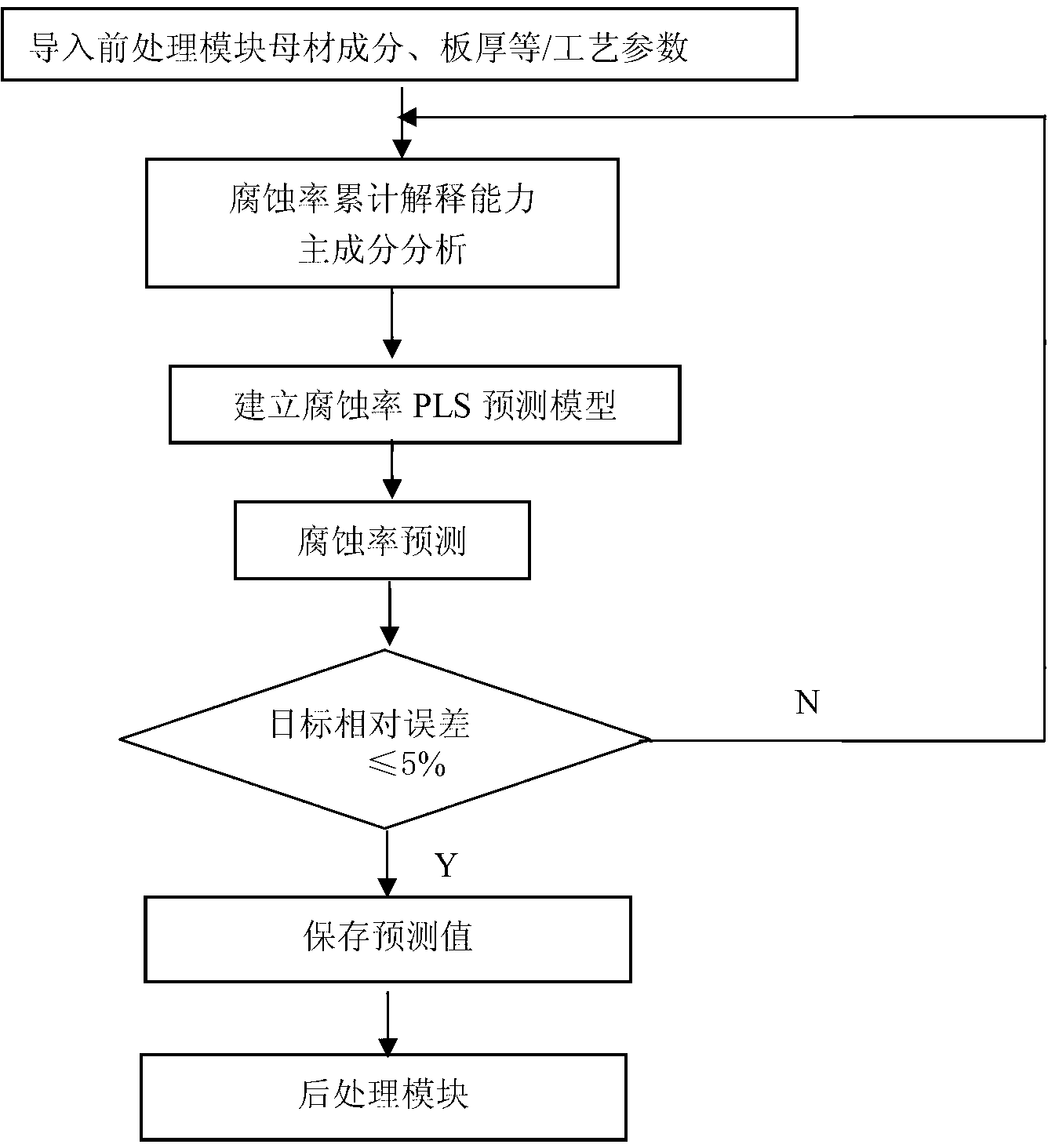

Method used

Image

Examples

Embodiment 1

[0044] Taking the St12 plate / St12-based galvanized sheet tailor-welded blank with an equal thickness of 1.2mm as an example, the welding process adopts single-sided welding and double-sided forming. The welding process parameters are: power P=1525~1850W, welding speed 1.6~2.0m / min , Spot diameter Φ0.3mm ~ 1mm, absorption rate 0.7, focal length of welding lens is 127mm.

[0045] Using MATLAB software to map the existing welding process parameters and mechanical properties beta j ,j=0,1,...k,i=1,2) to perform PLS calculation, the algorithm steps are as follows.

[0046] Step 1: Relevant process data of weldment samples (≥9), as shown in Table 1.

[0047] Table 1 Process parameters and experimental results of weldment samples

[0048]

[0049] Step 2: Investigate the issue of multiple correlations between input variables. It can be seen from Table 2 that the multiple correlations between input variables are obvious.

[0050] Table 2 Correlation coefficient matrix between ...

Embodiment 2

[0070] Taking the 1.2mm St12 / St16 tailor-welded blank as an example, the welding process adopts single-sided welding and double-sided forming. The welding process parameters are: power P=850~1450W, welding speed 1.0~2.0m / min, spot diameter Φ0.3mm ~1mm, the absorption rate is 0.7, and the focal length of the welding lens is 127mm. The modeling and optimization process and steps are the same as in Example 1.

[0071] Step 1: Relevant process data of weldment samples (≥9), as shown in Table 5.

[0072] Table 5 Process parameters and experimental results of weldment samples

[0073]

[0074] After steps 2 to 4 described in Example 1, the PLS prediction model of corrosion resistance is obtained, as shown below.

[0075] Corrosion rate η of tailor welded blank is:

[0076] η=-0.0058x 1 +0.7836x 2 -2.1347x 3 +19.0347

[0077] x in the above formula 1 — laser power (W), x 2 — Welding speed (m / min), x 3 — Spot diameter (mm).

[0078] Step 5: Prediction accuracy inspection...

Embodiment 3

[0084] Taking 0.8mmSt16 / 1.5mmSt12 base galvanized tailor-welded blank as an example, the welding process adopts single-side welding and double-side forming, and the welding process parameters, modeling and optimization process and steps are the same as those in Embodiment 1.

[0085] Step 1: Relevant process data of weldment samples (≥9), as shown in Table 7.

[0086] Table 7 Process parameters and experimental results of weldment samples

[0087]

[0088]

[0089] After steps 2 to 4 described in Example 1, the PLS prediction model of corrosion resistance is obtained, as shown below.

[0090] Corrosion rate η of tailor welded blank is:

[0091] η=-0.0068x 1 +0.8342x 2 -0.8657x 3 +19.5873

[0092] x in the above formula 1 — laser power (W), x 2 — Welding speed (m / min), x 3 — Spot diameter (mm).

[0093]Step 5: Prediction accuracy inspection and control

[0094] Import the process data of the pretreatment module into the corrosion resistance prediction module to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com