Method and device for automatic loading of roasting alloys in silicon steel production

A technology of automatic feeding and baking device, applied in the field of metallurgical industry, can solve the problems of increased operation interference, poor manual working environment, silicon burning loss, etc., and achieves the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

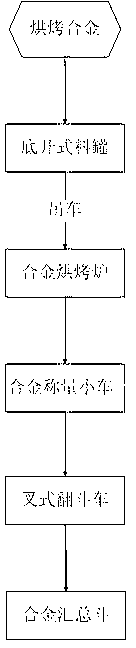

Image

Examples

Embodiment Construction

[0036] Below in conjunction with specific embodiment, the present invention is further described:

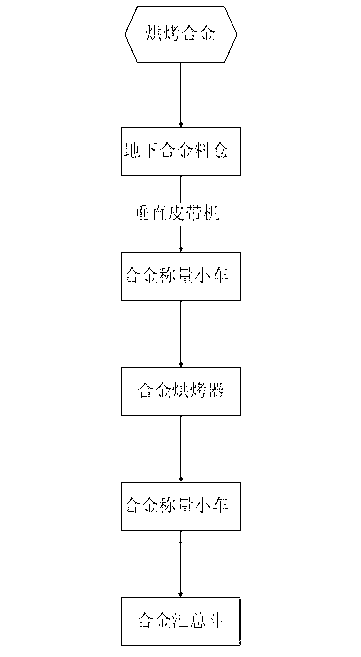

[0037] Such as Figure 4 The shown automatic feeding device for baking alloys used in silicon steel production includes a conveying device, a baking device, a summarizing device, and an electric control system connected to the three, wherein the conveying device is a vertical belt conveyor 2, and its The bottom end is connected to the alloy underground silo 1, and the top is provided with a feeding port, wherein the roasting device includes a plurality of alloy roasters 4 arranged side by side, and an upper and lower position along the alignment direction of the alloy roasters 4 is arranged in parallel. For the guide rails, a slidable upper weighing trolley 3 is installed on the upper guide rail, and the upper weighing trolley 3 can move to the feeding port, and the lower guide rail extends out of the area of the alloy roaster 4, and a slidable lower trolley is installed on it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com