Heating control method of TEG reboiler fire tube

A heating control and reboiler technology, applied in chemical instruments and methods, control combustion, lighting and heating equipment, etc., can solve the problems of easy flameout, large inertia, large lag, etc., to solve the problem of reboiler flameout, Optimizing the adjustment and control method of the burner and solving the effect of overshooting the temperature of the TEG solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

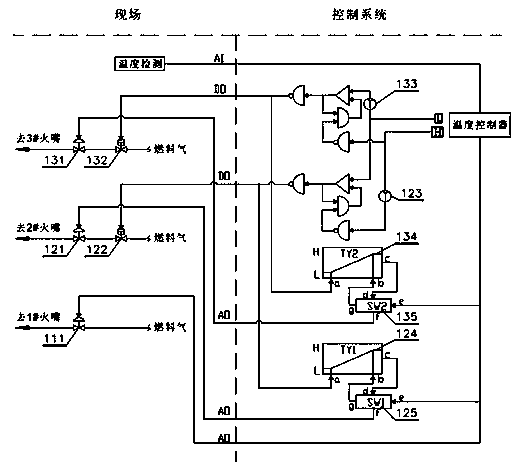

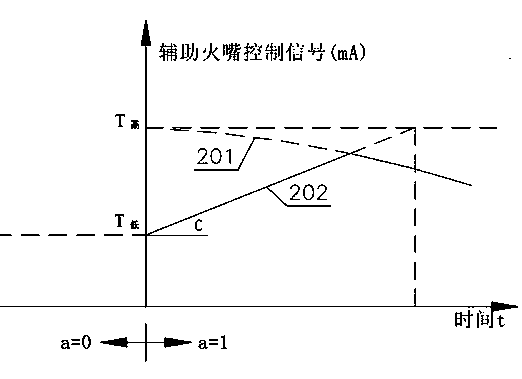

[0013] The TEG reboiler of the present invention adopts multiple burners, and each burner fuel gas pipeline is provided with a fuel gas regulating valve and a fuel gas cut-off valve, which are used to control the burner fuel gas flow and burner switching. In order to prevent the burner from defiring or tempering, each burner is controlled by high and low limit. A specific burner (main burner) among the multiple burners is always put into combustion, and the number of other burners (auxiliary burners) put into combustion is increased or decreased one by one according to the heat load requirement. In order to reduce the impact of adding auxiliary burners on the flame stability of the main burner, the multiple burners of the TEG reboiler are arranged in the lowest layer of the reboiler according to the main burner, and the auxiliary burners are arranged above the main burner. arrangement.

[0014] When the heat load demand of the reboiler changes, the TEG reboiler nozzle switchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com