Method for strengthening reinforced concrete beam through distributed external prestressing cables

A reinforced concrete beam, external prestressing technology, applied in bridge reinforcement, bridge, bridge maintenance and other directions, can solve the problems of complex tension anchor point structure, poor fire resistance and durability, large diameter of steel wire rope, etc., to achieve easy reinforcement operation, The effect of good durability and fire resistance, and low engineering cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

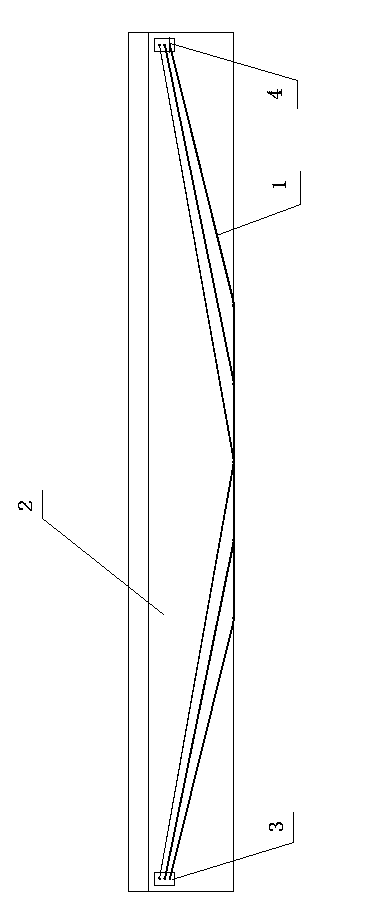

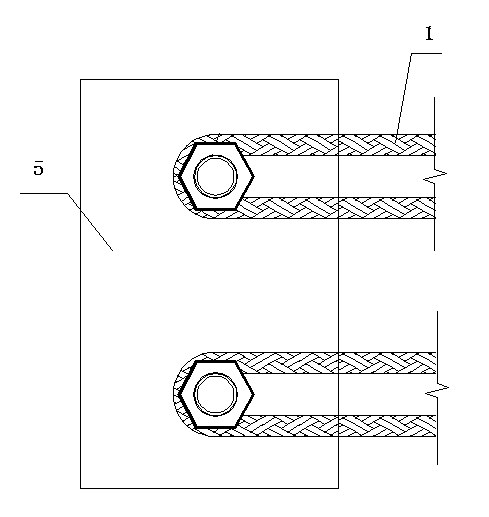

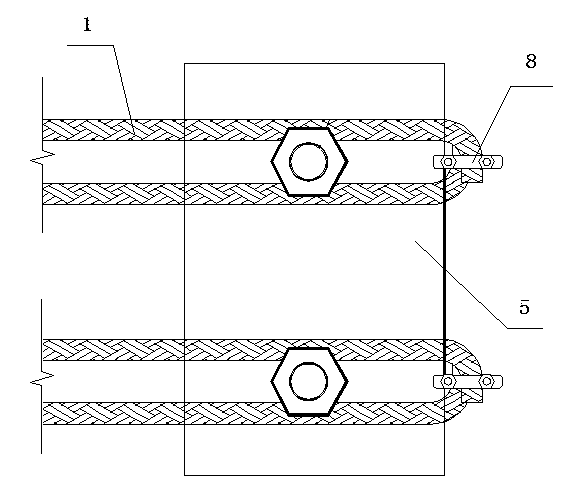

[0022] Embodiment 1, with reference to Figure 1-4 , Image 6 , a method for strengthening reinforced concrete beams with dispersed external prestressed cables, the steps are as follows:

[0023] (1) The first choice is to remove the loose part of the surface of the reinforced concrete beam 2, and clean the floating dust; then according to the design requirements, set the left anchor bolt 3 and the right anchor at the corresponding positions on both sides of the reinforced concrete beam 2 Bolt 4; open a 5mm deep notch in the bottom middle of the reinforced concrete beam 2 for installing the steering rod 7;

[0024] (2) Using the continuous winding method, the cable material 1 is bypassed by the anchor bolt 3 at the left end, and the anchor plate 5 is installed after the cementing material is applied to the anchorage of the anchor bolt 3 at the left end; Connect and tighten the material 1, fill the anchorage of the anchor bolt 4 at the right end with cementing material, insta...

Embodiment 2

[0025] Embodiment 2, with reference to Figure 5 , in the method for strengthening reinforced concrete beams with dispersed external prestressed cables described in embodiment 1: the tensioning device includes a base 9 with screw holes, and several screw rods 10 are installed on the base 9 through the mounting holes , The screw 10 is provided with a hooked head;

Embodiment 3

[0026] Embodiment 3, in the method for strengthening reinforced concrete beams with dispersed external prestressed cables described in Embodiment 1 or 2: the cable material 1 is selected from steel strands, steel wire ropes or high-strength FRP cables.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com