Main emission peak changeable and adjustable fluorescent material and preparation method thereof

A technology of fluorescent materials and main peaks, applied in luminescent materials, chemical instruments and methods, sustainable buildings, etc., can solve the problems of large light decay of fluorescent powders, inability to meet the color rendering properties of white LEDs, low thermal stability, etc. Effect of Luminous Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

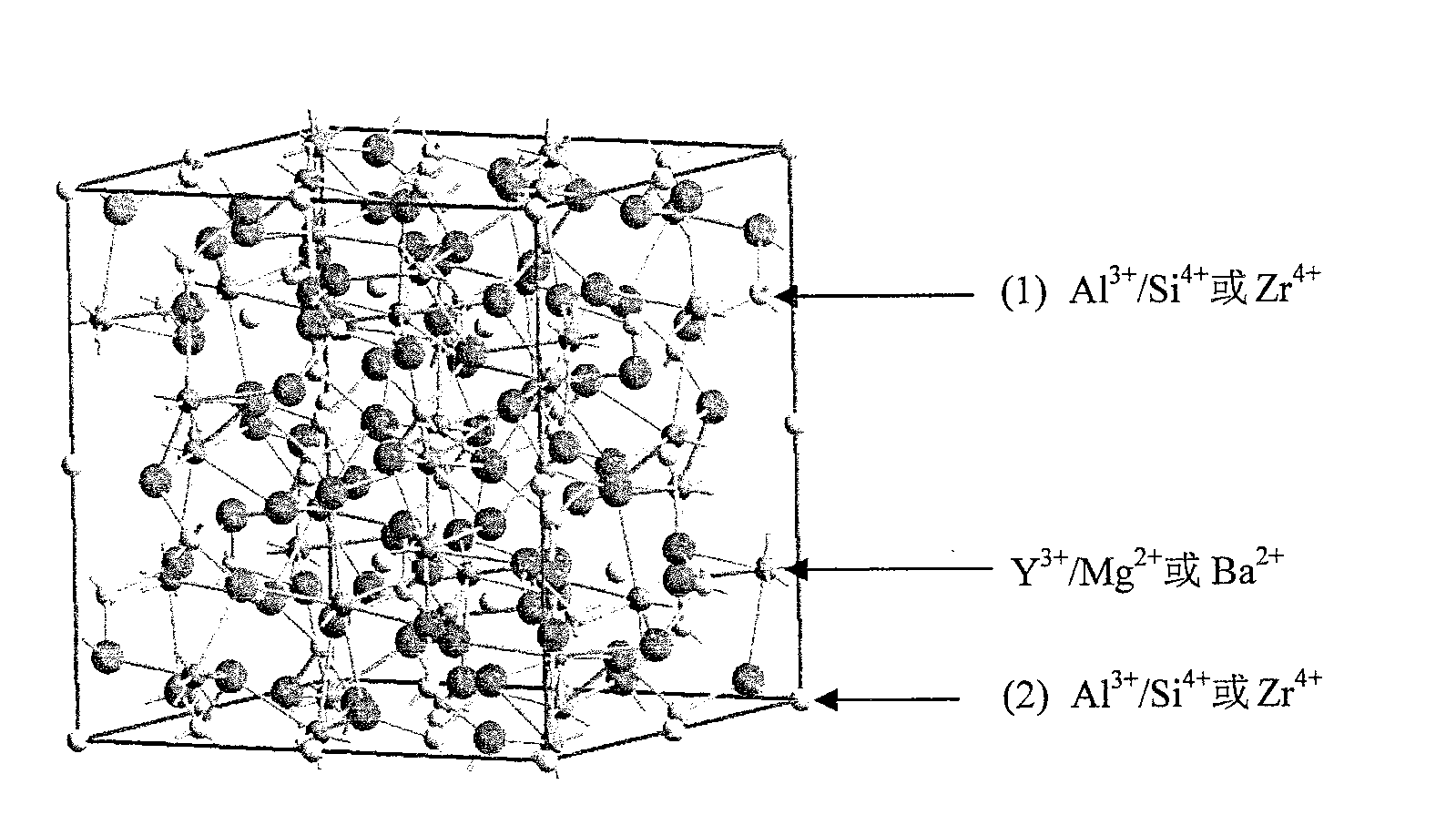

[0042] According to the general chemical formula M x-z Y 6-x-y-z Al 11-x L x o 25.5-0.5k f k :y.Ce 3+ , z.Mn 2+ , will analyze pure MgO, MgF 2 , NH 4 F. Al 2 o 3 , AlF 3 , SiO 2 , ZrO 2 、BaF 2 , MnCO 3 and CeO 2 , mix the ingredients according to the chemical composition ratio of Table 1, 2 and 3, mix the ingredients in an airtight container for 40 hours, then put the mixture in H 2 %<5% atmosphere, heat preservation in a reduction furnace at 1620°C for 6 hours, cool, crush and classify, and pass through a 500-mesh sieve to obtain an alkaline earth fluorooxyaluminosilicate fluorescent material with a particle size of about 3-20 μm. Combined with blue LED chips (450-460nm) and packaged to obtain white LEDs.

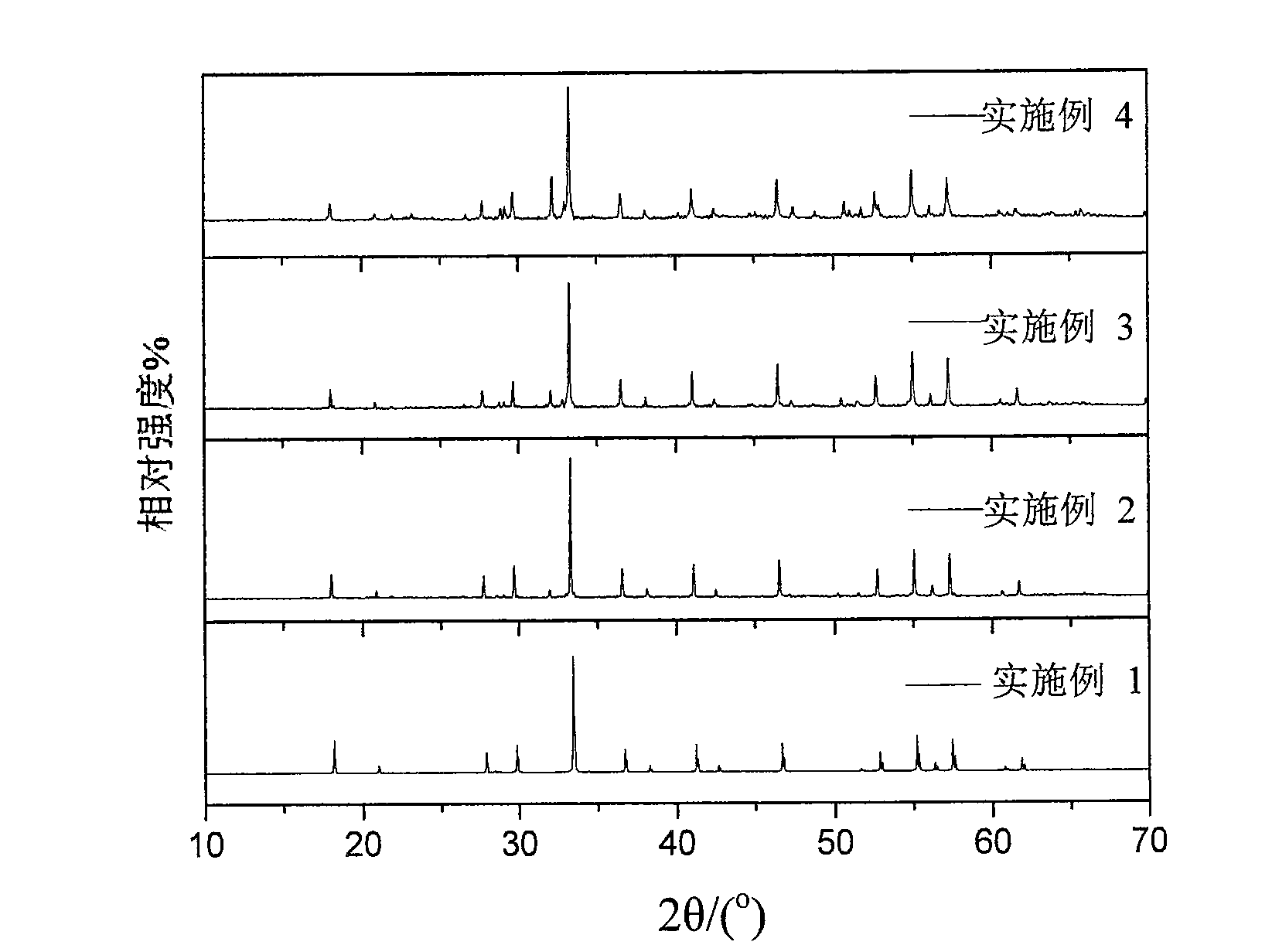

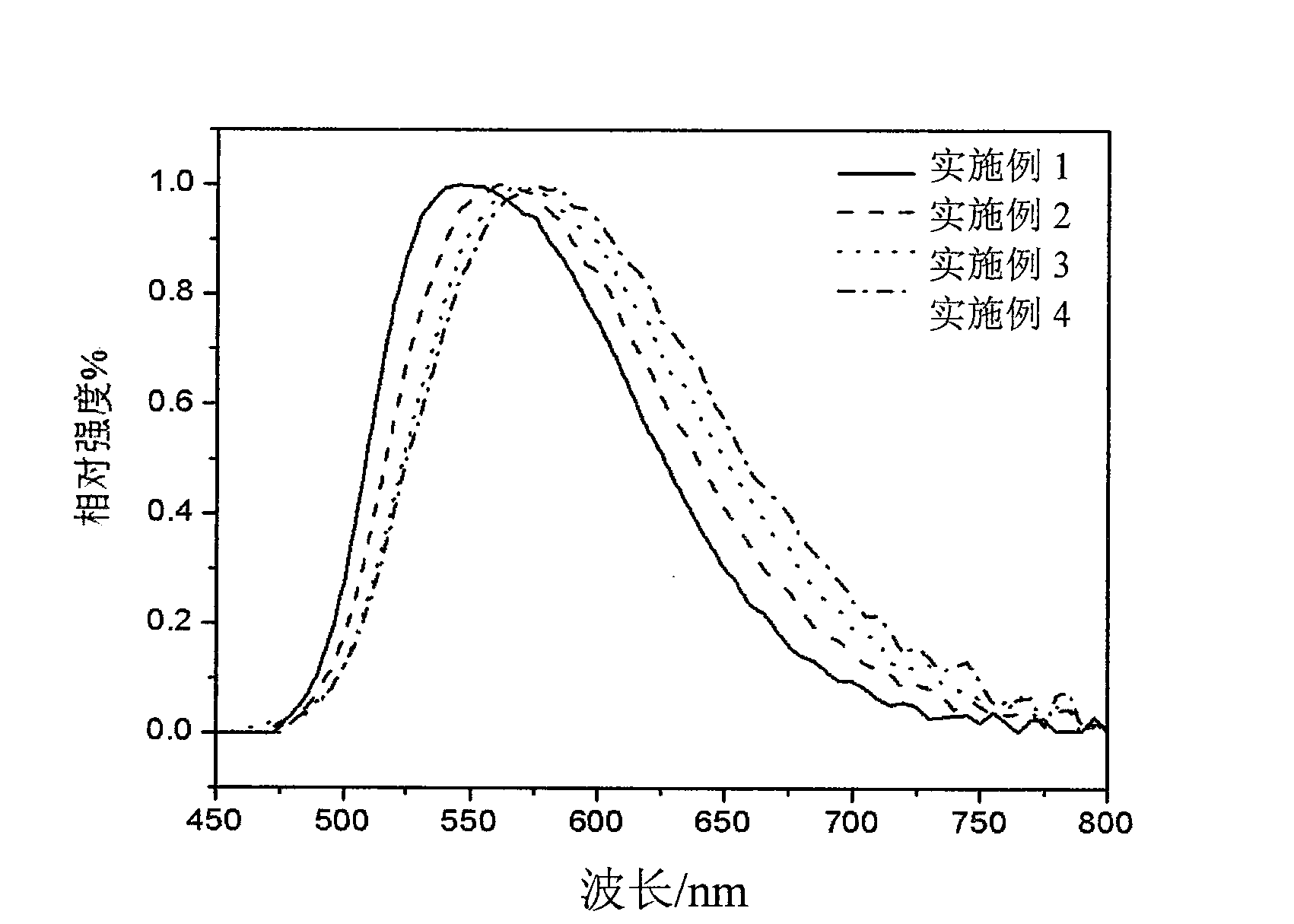

[0043] The main peak of phosphor emission is determined by the national phosphor test standard GB / T 14634.2-2010, and the excitation spectrum is tested by FLS-920 transient steady state fluorescence spectrometer. The crystal structure (XRD) of the phospho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com