Antitoxic regeneration solution of deactivated SCR denitration catalyst, and preparation method thereof

A denitration catalyst and regeneration liquid technology, which is applied in catalyst regeneration/reactivation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of deactivation, mechanical strength drop, catalyst poisoning, etc., and prolong the service life. , the effect of improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of active replenishing liquid, weigh 2.5wt% ammonium metavanadate and 5wt% ammonium tungstate in oxalic acid solution according to weight ratio, adjust pH value to 6, stir mechanically for 30 minutes, mix evenly, and prepare active Supplementary fluid;

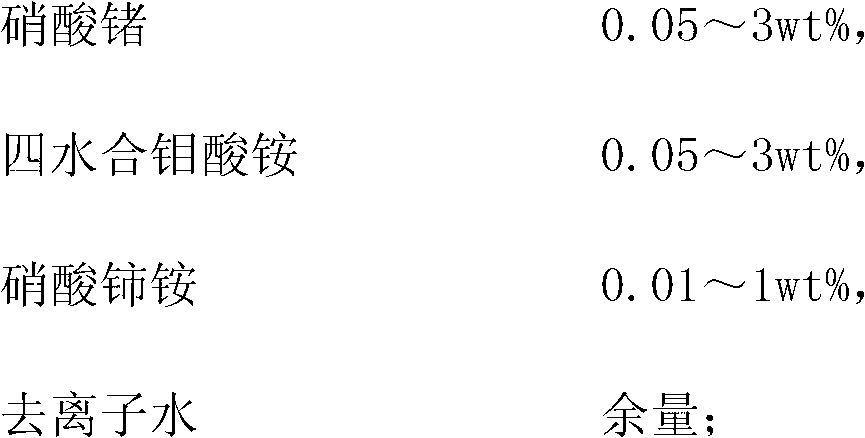

[0030] 2, the preparation of anti-toxic modification liquid, take by weight 0.05wt% germanium nitrate, 0.05wt% ammonium molybdate tetrahydrate, 0.01wt% cerium ammonium nitrate, add deionized water to dissolve, mechanically stir for 30min, make It is mixed evenly and formulated into an anti-toxic modified liquid;

[0031] 3. Preparation of additive solution, weigh 0.05wt% penetrating agent JFC, 0.05wt% dispersant sodium dodecylbenzene sulfonate, 0.05wt% adhesive polyvinyl alcohol by weight, add deionized water to dissolve, Stir mechanically for 10 minutes to make it evenly mixed and prepare an additive solution;

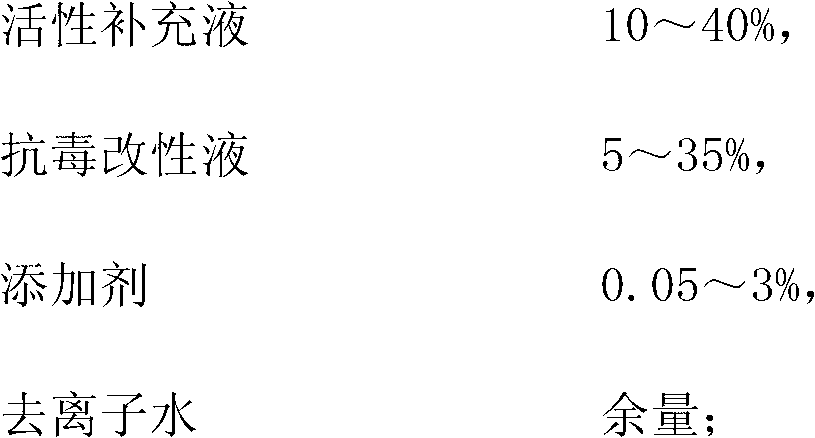

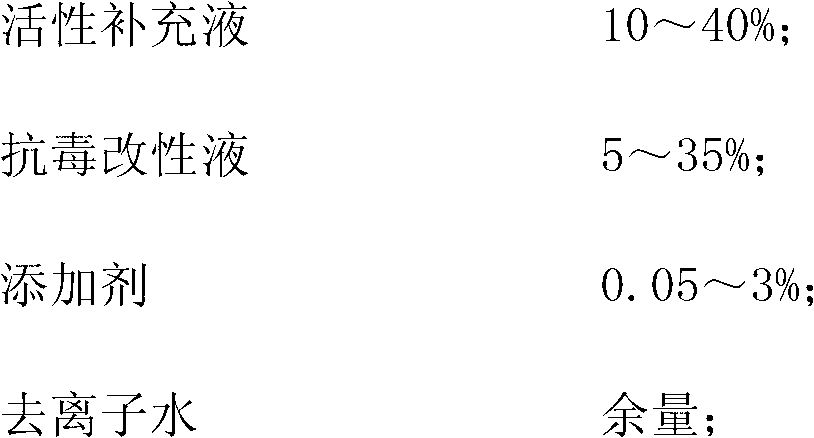

[0032] 4. Add the active replenishing liquid and the anti-toxic modifying liquid to the add...

Embodiment 2

[0034] 1. Preparation of active replenishing solution, weigh 10wt% ammonium metavanadate and 25wt% ammonium tungstate in oxalic acid solution by weight, adjust the pH value to 3, stir mechanically for 60 minutes, make it evenly mixed, and prepare active supplement liquid;

[0035] 2. Preparation of anti-toxic modified solution, weigh 3wt% germanium nitrate, 3wt% ammonium molybdate tetrahydrate, and 1wt% cerium ammonium nitrate by weight ratio, add deionized water to dissolve, and stir mechanically for 60 minutes to make it evenly mixed , formulated as an anti-toxic modified liquid;

[0036] 3. Preparation of additive solution, weigh 1wt% penetrating agent JFC, 1wt% dispersant sodium dodecylbenzene sulfonate, 1wt% adhesive polyvinyl alcohol by weight, add deionized water to dissolve, mechanically stir for 30min , make it evenly mixed, and prepare additive solution;

[0037] 4. Add the active replenishing liquid and the anti-toxic modifying liquid to the additive solution in s...

Embodiment 3

[0039] 1. Preparation of active replenishing liquid, weigh 5wt% ammonium metavanadate and 15wt% ammonium tungstate and dissolve in the mixed acid solution of oxalic acid and citric acid, adjust the pH value to 5, stir mechanically for 45min to make it evenly mixed , formulated as an active supplement;

[0040] 2, the preparation of anti-toxic modification liquid, take by weight 1.5wt% germanium nitrate, 1.5wt% ammonium molybdate tetrahydrate, 0.5wt% cerium ammonium nitrate, add deionized water to dissolve, mechanically stir for 45min, make It is mixed evenly and formulated into an anti-toxic modified liquid;

[0041] 3. The preparation of additive solution, weigh 0.5wt% penetrating agent JFC, 0.5wt% dispersant sodium dodecylbenzene sulfonate, 0.5wt% adhesive polyvinyl alcohol by weight, add deionized water to dissolve, Stir mechanically for 20 minutes to make it evenly mixed and prepare an additive solution;

[0042]4. Add the active replenishing liquid and the anti-toxic mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com