A kind of light-emitting diode laser etching method

A laser etching method and light-emitting diode technology, which are applied in laser welding equipment, electrical components, circuits, etc., can solve the problems of product yield impact, high cost, complex process, etc., to reduce product cost, reduce formation time, The effect of reducing the length of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

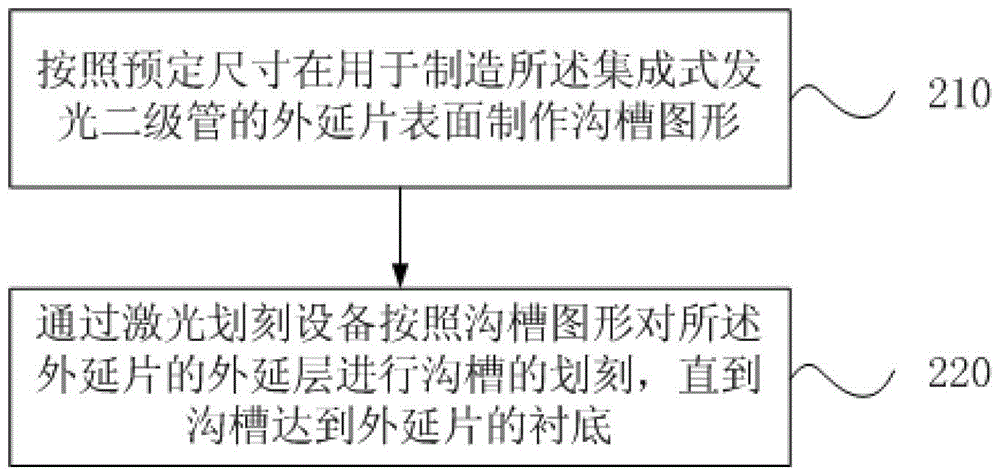

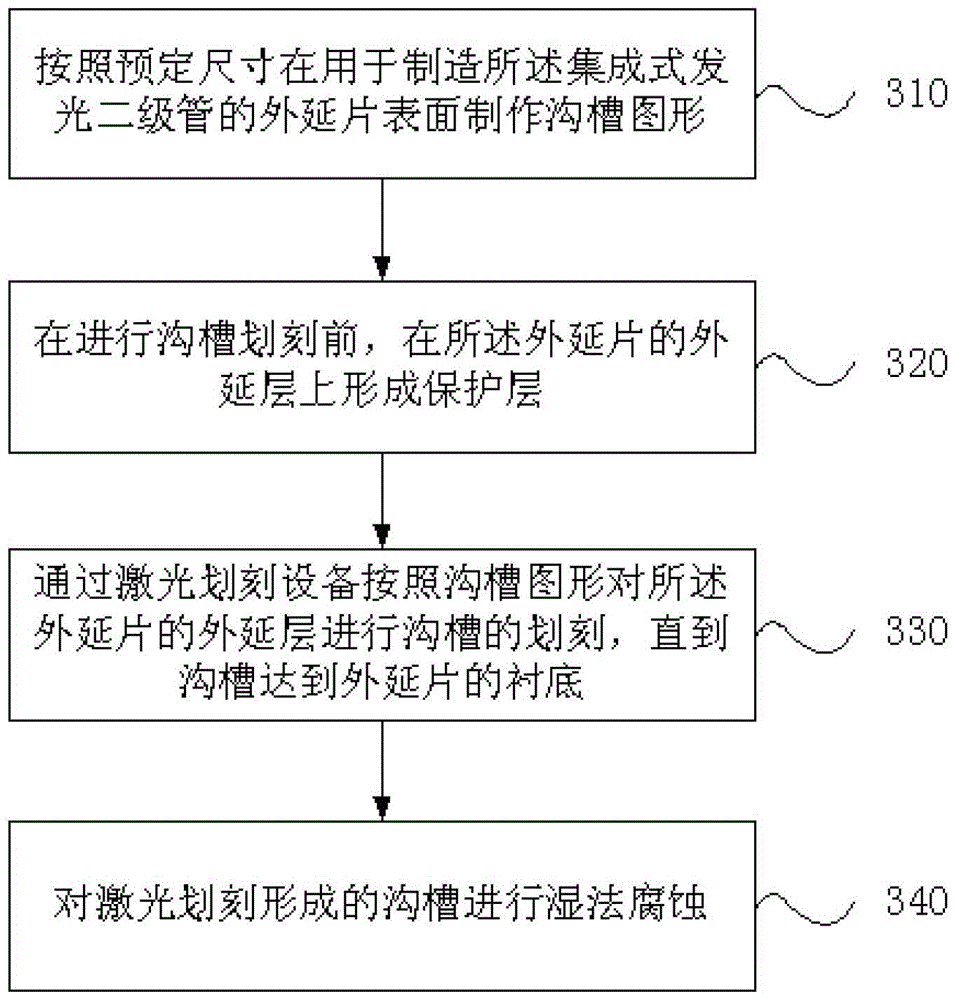

[0032] figure 2 It is a flow chart of the laser etching method for light-emitting diodes according to the first embodiment of the present invention. like figure 2 As shown, the method includes:

[0033] Step 210, making groove patterns on the surface of the epitaxial wafer used to manufacture the integrated light emitting diode according to predetermined dimensions.

[0034] Step 220, using laser scribing equipment to scribe grooves on the epitaxial layer of the epitaxial wafer according to the groove pattern until the groove reaches the substrate of the epitaxial wafer.

[0035] Wherein, the etching depth of the groove is controlled by controlling the marking speed and / or laser power of the laser marking equipment so that the marking depth reaches the substrate, and the marking speed and laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com