Method for determining incident angle of particles in three-dimensional cellular model etching process

A technology of incident angle and particles, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effects of avoiding processing, reducing solutions, and reducing computational complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

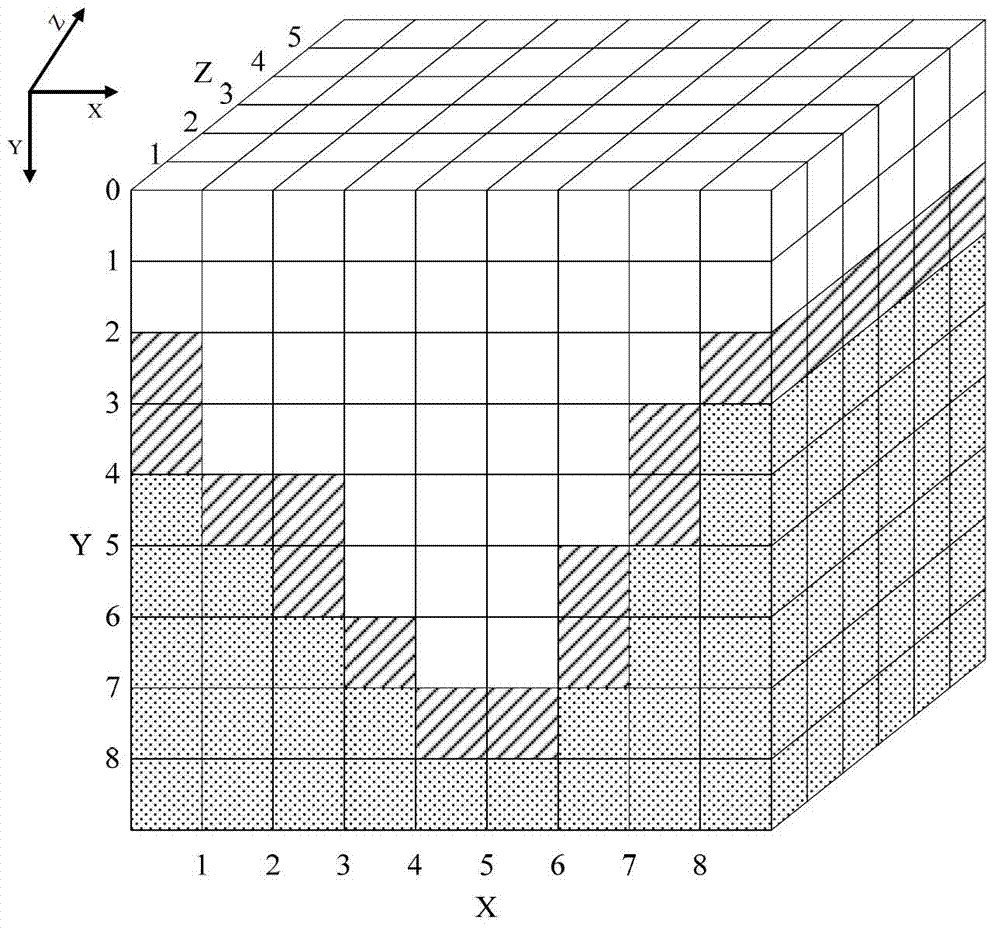

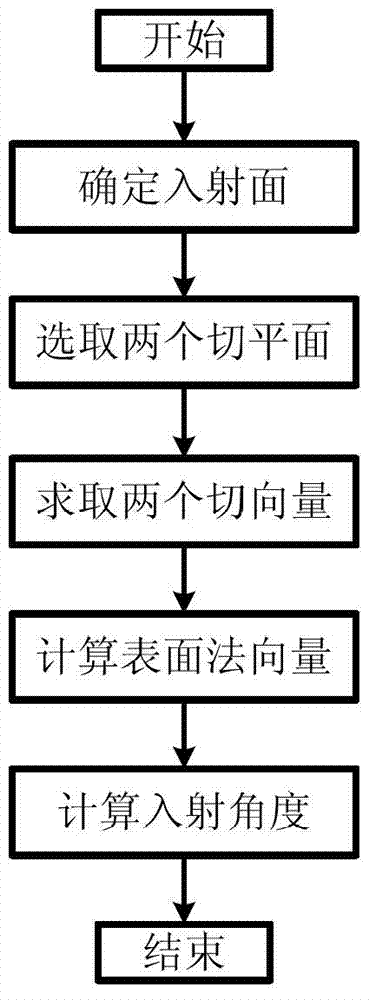

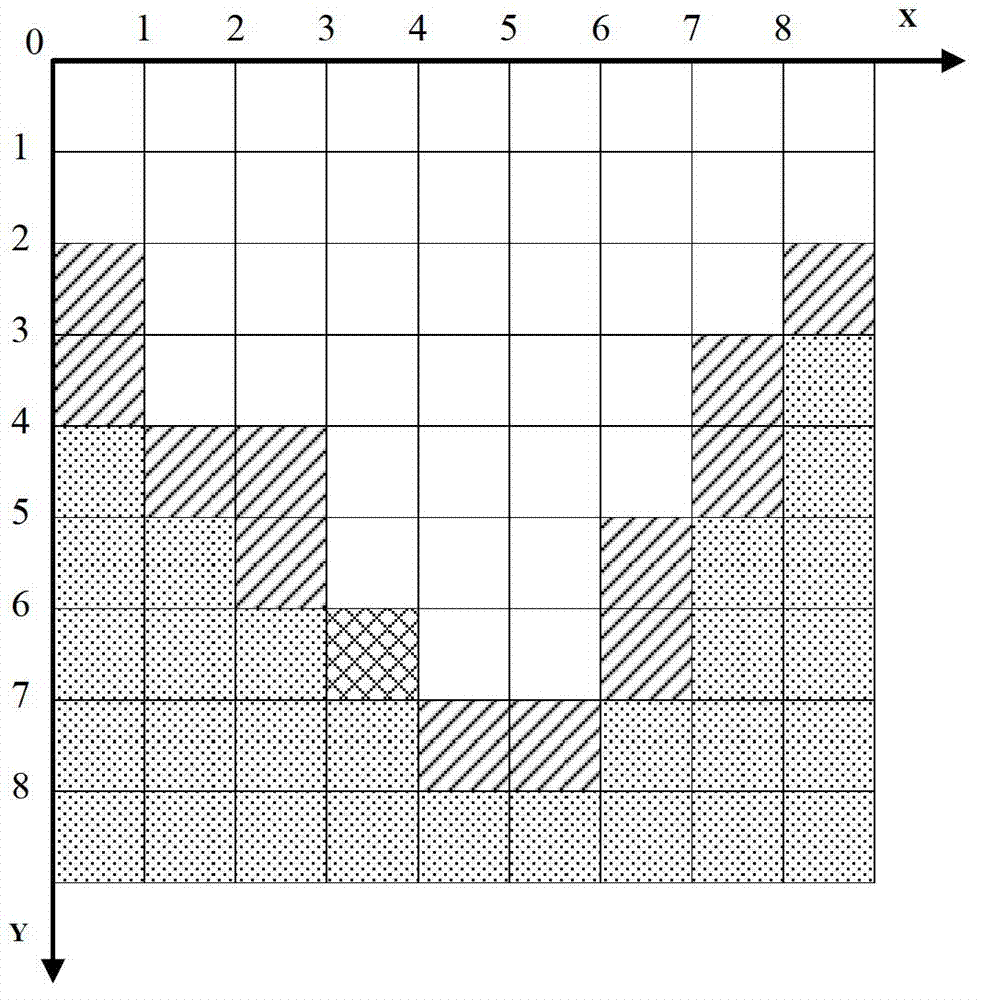

[0017] The method for determining the incident angle of particles in the three-dimensional cell model-oriented etching process of the method of the present invention is described in detail in conjunction with the accompanying drawings and embodiments as follows:

[0018] A method for determining the particle incident angle in the three-dimensional cellular model etching process of the present invention is characterized in that: the method first selects two tangent planes perpendicular to the incident surface according to the incident direction of the etching particles; Select the surface cells around the incident point on a tangent plane, and use its position coordinates as data sampling points to perform fitting calculations using a two-dimensional curve fitting method, and then obtain the tangent vectors of the incident point in the direction of the two coordinate axes; finally The vector cross product of these two tangent vectors is used to obtain the surface normal vector o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com