Tower-type solar heat collection heliostat field control system based on multi-layer architecture

A tower type solar energy and control system technology, applied in the direction of using feedback control, etc., can solve the problem that the direction of the photosensitive sensor cannot be adjusted in real time, is not suitable for industrial production and market competition, and the performance of the heliostat group controller is high, and achieves high precision. The effect of automatically tracking the sun's running trajectory, the scheduling method and device is reasonable, and improving the working efficiency of the mirror field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

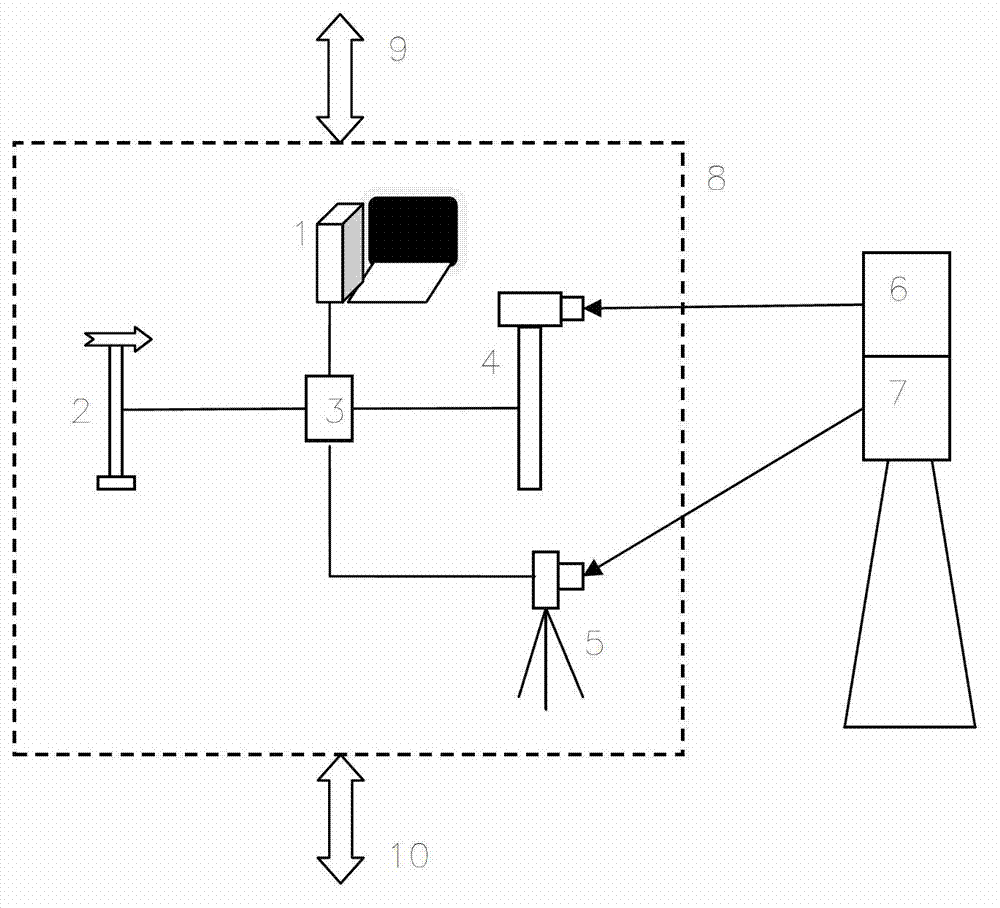

[0040] Field-level scheduling and control devices such as figure 1 As shown, the heliostat field control and scheduling device (8) includes a host (1), a weather monitor (2), a host communication interface (3), an infrared camera (4), and a high-precision camera (5).

[0041] The functions of the host computer (1) are: to receive instructions from the control platform of the tower heat collection system and to feed back relevant information; to send instructions to the control devices of each heliostat mirror group and to receive relevant information fed back; to calculate the geographic location of the mirror site to observe the orbit of the sun Relevant data is sent to each heliostat mirror group; according to the requirements of the time period and the temperature field change of the photothermal conversion system, determine the relevant heliostat mirror group and heliostats that perform tasks such as spot projection and defocusing, and the mirror field processing measures f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com