A fixed fly ash sampling device and method for a coal-fired boiler

A sampling device and coal-fired boiler technology, applied in the field of fly ash sampling, can solve problems such as not suitable for on-site application in power plants, expensive, prone to various failures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

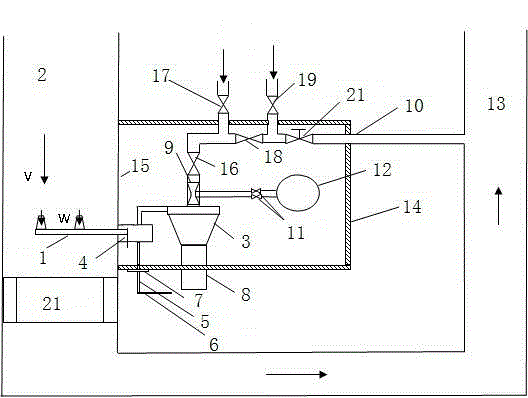

[0060] figure 1 Among them, the coal-fired boiler fixed fly ash sampling device of this embodiment includes a sampling device, a cyclone separation and storage device, a flue gas flow measurement system, a heating device, a preheating and a blowback system;

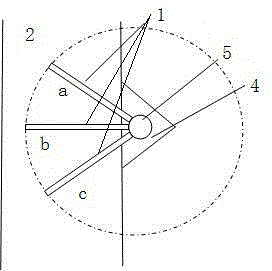

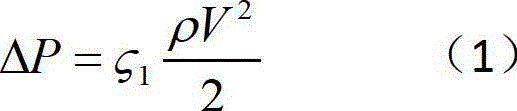

[0061] The sampling device includes a sampling gun 1 and a rotating device. The gun head of the sampling gun 1 is placed in the inlet flue 2 of the air preheater, and the tail of the gun is connected to the cyclone separation device 3; The first sampling gun, the sampling gun 1 is provided with two sampling ports, and the suction speed of the two sampling ports is designed to be exactly the same. There is a suction static pressure measuring hole inside the sampling port, and a flue gas static pressure measuring hole on the outside of the gun head. By adjusting the static pressure balance, the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com