Multi-channel self-adaptive high-precision LVDT data acquisition and measurement system and method

A technology of data acquisition and measurement method, applied in the direction of measuring force, transmission system, measuring device, etc., can solve the problems of vibrating wire distortion, frequent failure of vibrating wire strain sensor, inaccurate measurement of vibrating wire strain sensor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

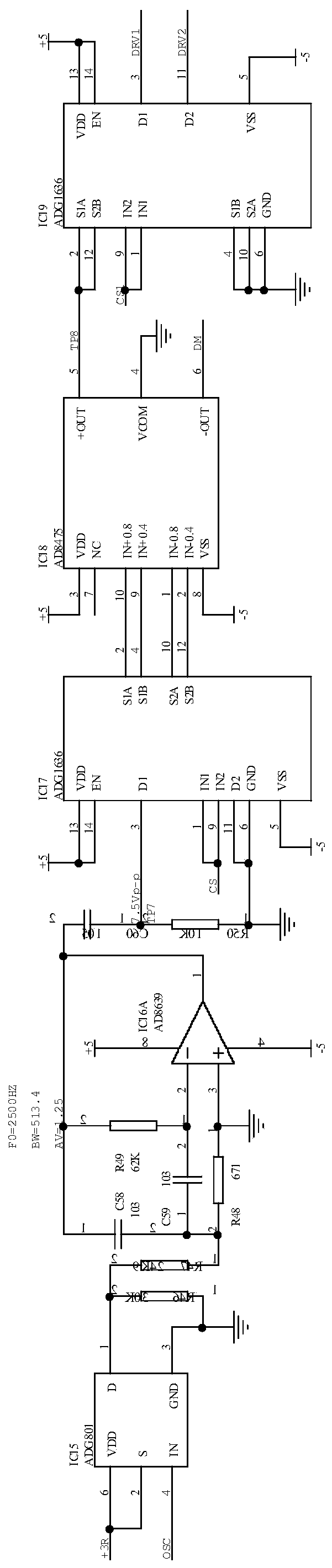

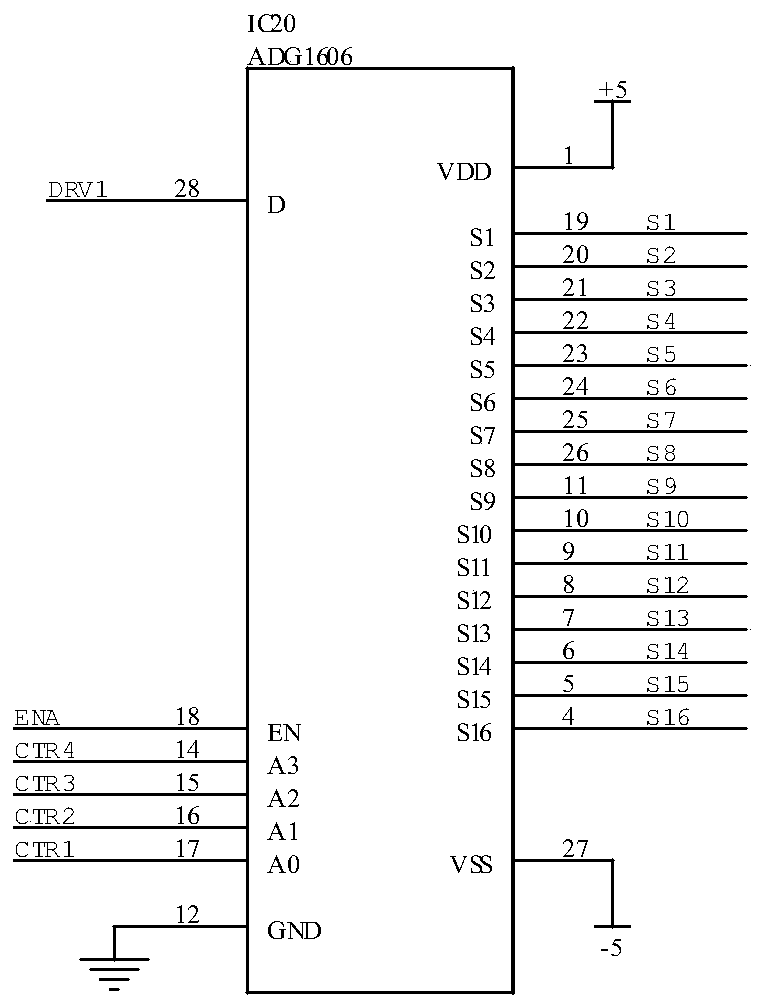

[0101] The main technical parameters of the embodiment of the present invention are: a. 32LVDT sampling channel. b. An LVDT sensor with free movable ends is used, and the two ends of the LVDT sensor are fixed on the object to be measured. The length of the two ends (fixed ends) of the LVDT is 150 mm. c. GPRS remote wireless data interaction and Bluetooth short-range data interaction are adopted. d. The axis movement direction of the measured object is consistent with the movement direction of the LVDT sensor's inclined iron. e. The measurement environment temperature range is -10℃-65℃. f. The interval between two adjacent samples is 1 hour.

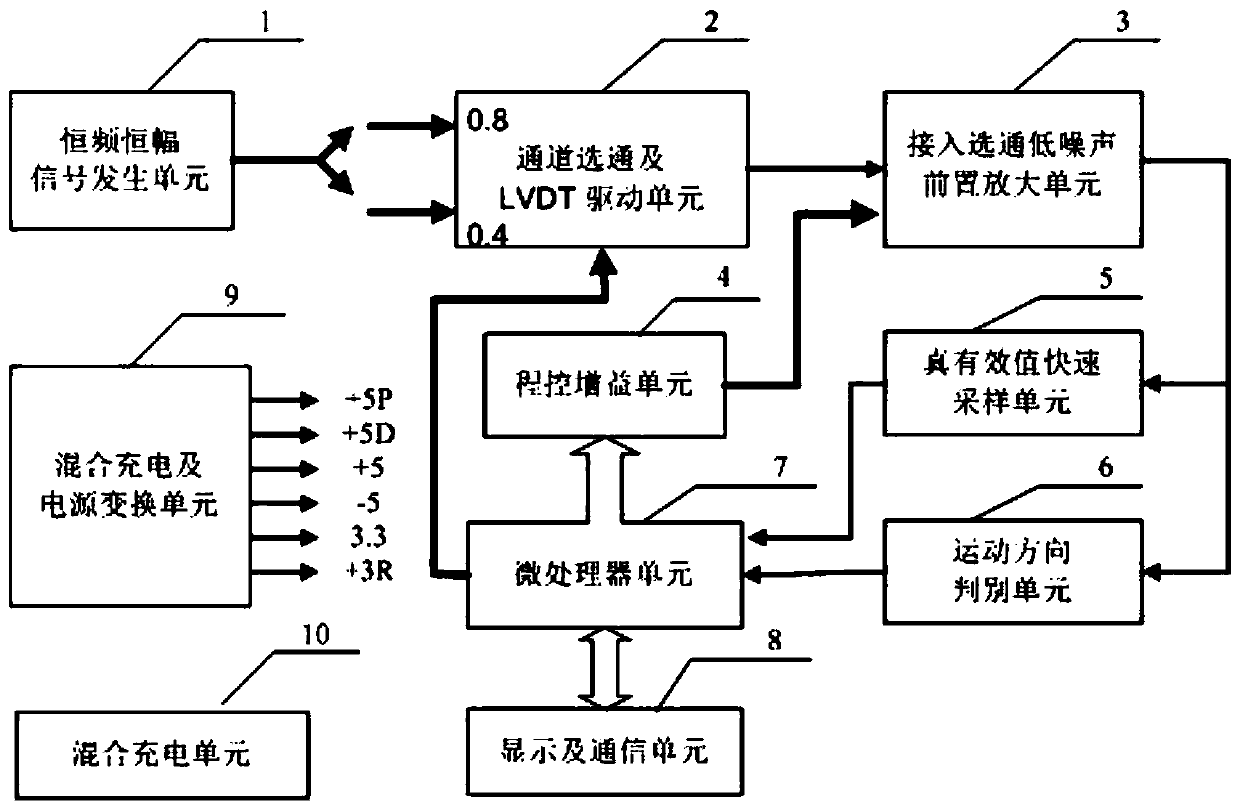

[0102] See Figure 2 to Figure 20 . A multi-channel self-adaptive self-calibration high-precision LVDT data acquisition and measurement system, consisting of a constant frequency and constant amplitude signal generating unit 1, a channel strobe and LVDT drive unit 2, a gated low noise preamplifier unit 3, and a programmable gain unit 4. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com