Quick gap electromagnetic measurement method and sensor device

A sensor device and electromagnetic measurement technology, applied in the direction of measuring devices, using electrical devices, using electromagnetic means, etc., can solve the problems of decreased sensitivity, prone to missed detection, unsatisfactory linearity, etc., to achieve linearity improvement, comprehensive measurement, Measuring the effect of fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

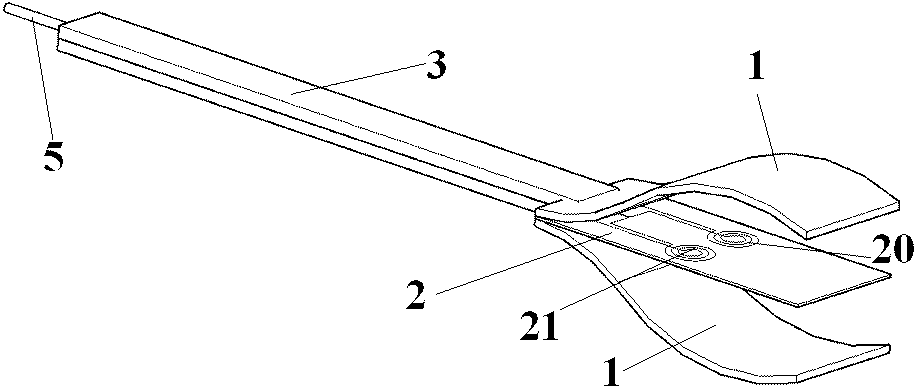

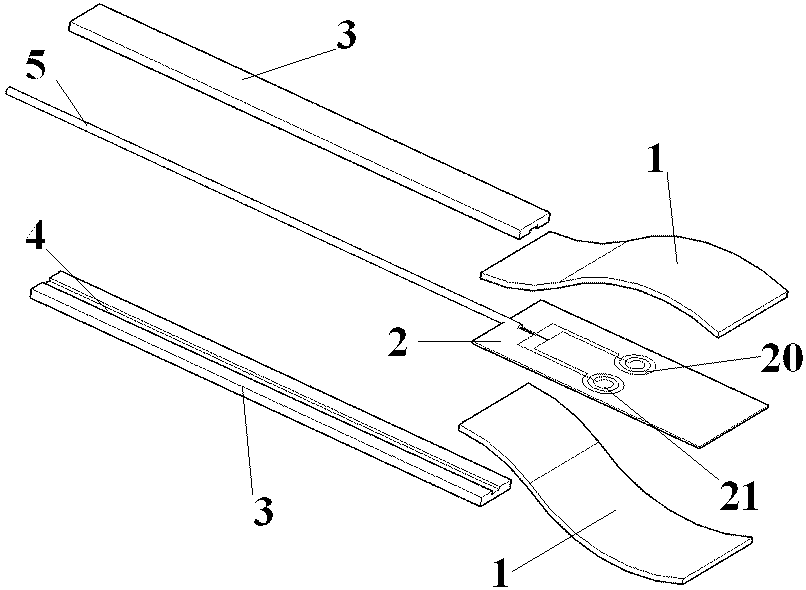

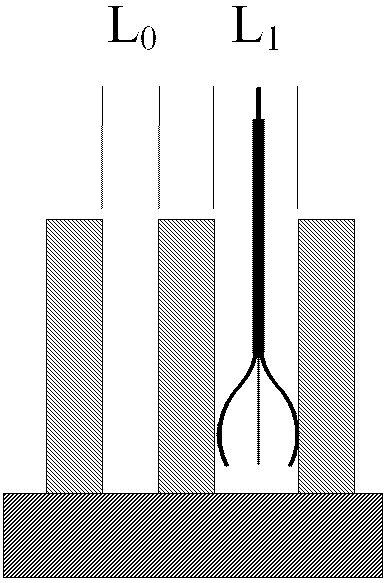

[0033] figure 1 , figure 2 , image 3 , Figure 4 In the shown first embodiment, a fast electromagnetic gap measurement method and a sensor device, the sensor device includes two metal sheets (1), a detection coil sheet (2), a hand-held rod (3), and a wire (5); The metal sheet (1) is made of spring steel. The size of the metal sheet (1) is determined according to the size of the inspected workpiece and the size of the gap between the inspected workpieces. The two metal sheets (1) are unilaterally welded or glued. , the other side of the two metal sheets (1) is bent and opened outwards, the gap between the two metal sheets (1) can be changed when the two metal sheets (1) are pressed by the outside, and the size of the opening in the natural state is slightly larger than the gap between the inspected workpieces ; The detection coil sheet (2) is unilaterally glued and fixed on the glued side of the two metal sheets (1), the detection coil sheet (2) is made of a flexible print...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com