Automatic ash cleaning type pneumatic plugboard isolating door

An isolation door and self-cleaning technology, which is applied in the configuration of valves, combustion methods, combustion equipment, etc., can solve the problems of door switch failure, inconvenience, and dust accumulation on pneumatic sliding plate isolation doors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

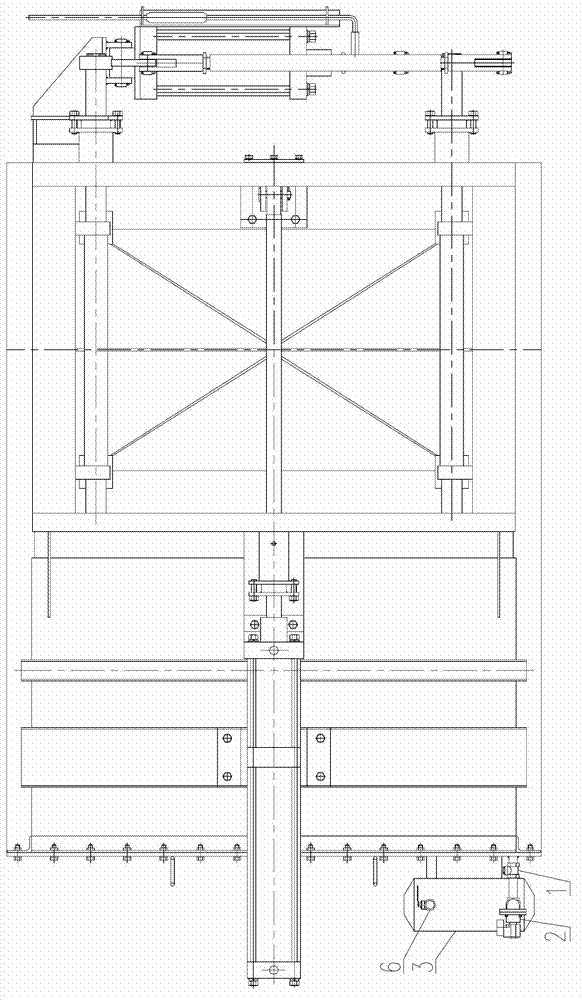

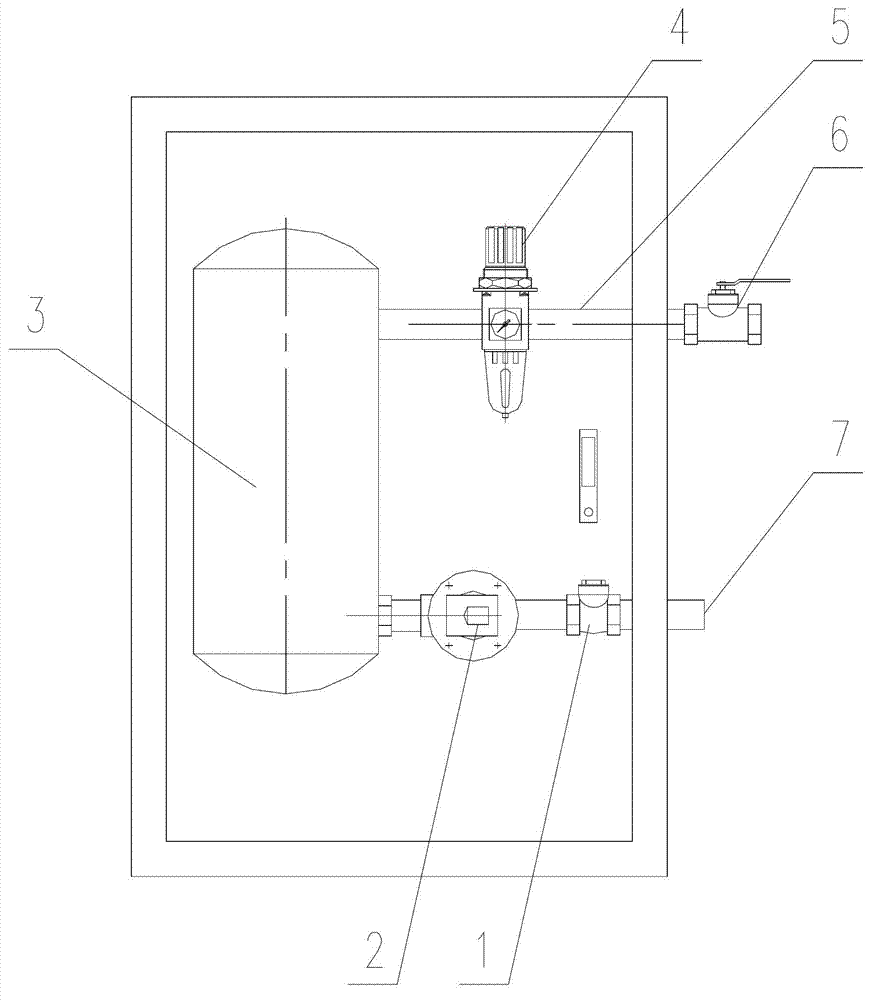

[0009] The present invention will be further described below in conjunction with the accompanying drawings.

[0010] like figure 1 , 2 As shown in the present invention, the self-cleaning pneumatic sliding plate isolating door dust cleaning device, the air inlet valve 6 on the air inlet pipe 5 is connected with the compressed air pipeline, and the air outlet pipe 7 is connected with the soot blowing pipe of the pneumatic sliding plate isolating door. The intake valve controls the compressed air pipeline, opens the intake valve 6, and the gas storage tank 3 stores gas. The control circuit controls the pulse solenoid valve 2 to blow high-pressure and high-frequency gas in a regular cycle to remove dust from the door panel track. The solenoid valve 2 is located in the storage tank. Between the gas tank 3 and the check valve 1, the check valve 1 controls the gas flow in the outlet pipe 7, cuts off the flow of the high-temperature and high-pressure gas in the air duct to the pulse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com