Open-contraction brake block rivet and production method thereof

A technology for brake pads and rivets, which is applied to rivets, connecting components, etc., can solve the problems of reducing the quality risk of rivets, unable to feed materials normally, etc., and achieves the effects of simple structure, reduced scrap rate, and stable product forming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

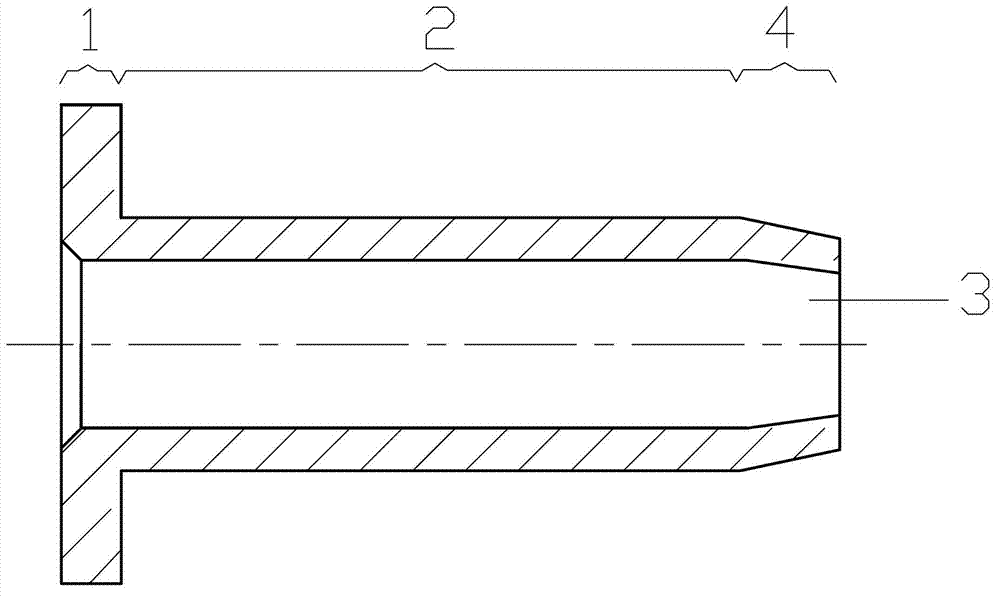

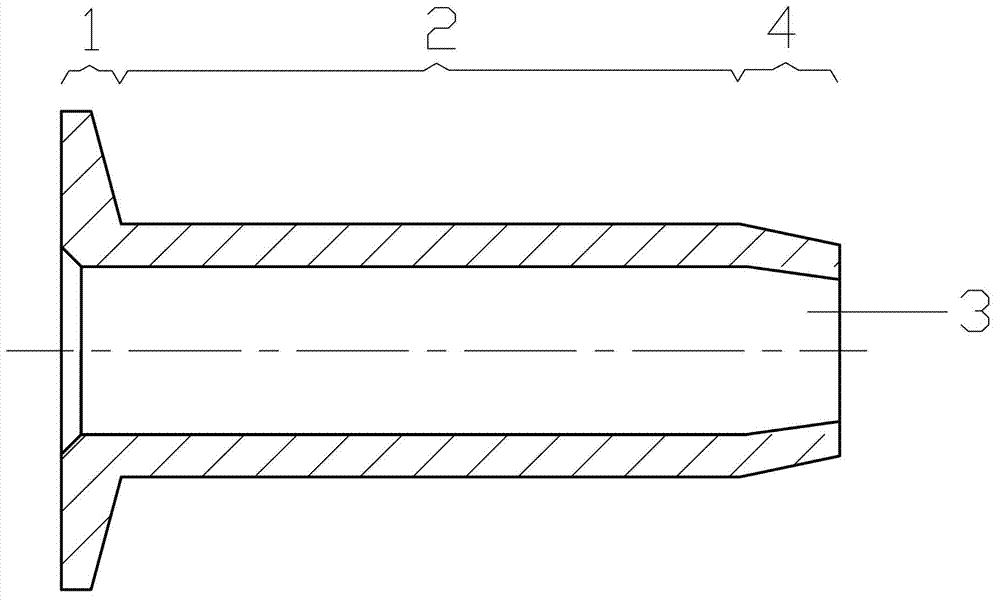

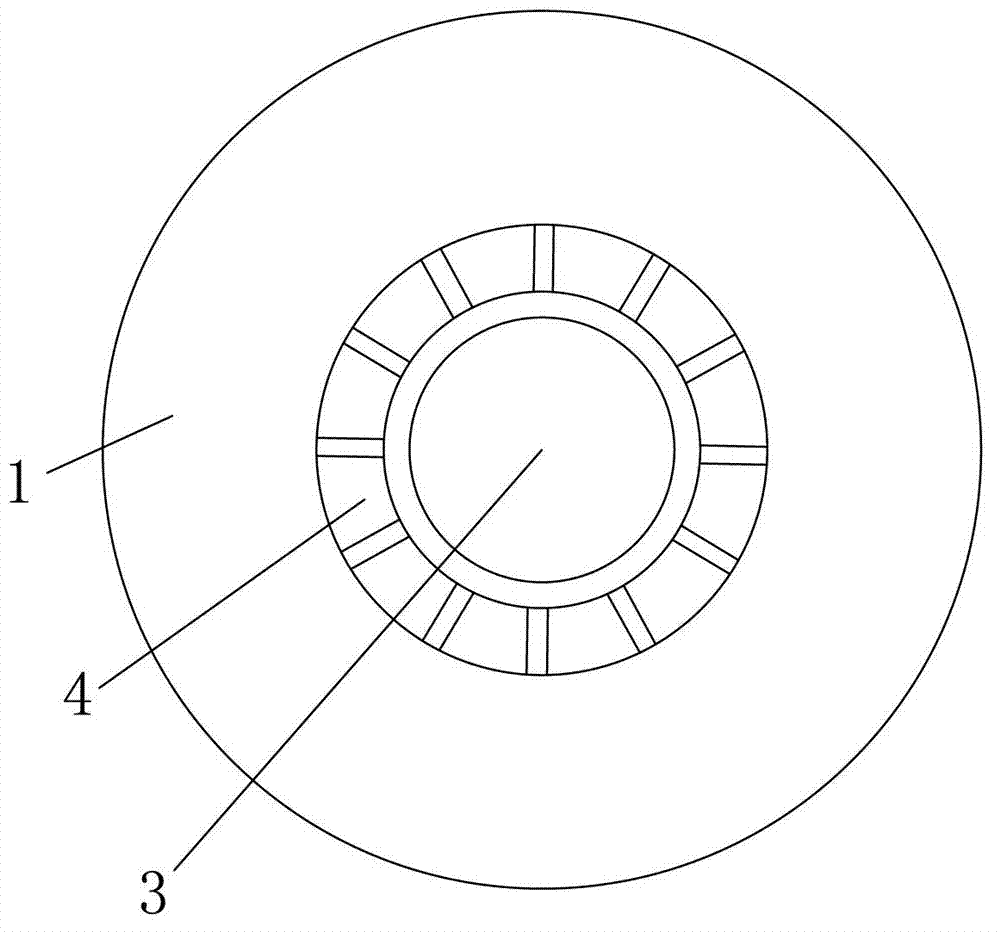

[0015] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3:

[0016] The shrinking brake pad rivet includes a head 1 and a shaft 2, the head and the shaft are integrally connected, the head and the shaft are provided with an axial through hole 3 formed by cold heading and drilling, the The end of the shaft is provided with a tapered portion 4 formed by cold extrusion and chamfering. The common machining chamfering treatment is easy to cause burrs on the surface of the part. If the thickness of the hollow rivet wall is too thin, the chamfering treatment will easily make the rivet scrapped directly. Therefore, the use of cold extrusion can enhance the strength of the rivet and reduce the processing time. Scrap rate.

[0017] The above-mentioned head has a frusto-conical shape with a through hole.

[0018] As a second embodiment of the structure of the present invention, the above-mentioned h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com