Method and apparatus for operating a screening wheel filter

A trommel screen and filter technology, which is applied in the field of running trommel filter machines and devices, can solve the problem of consuming cleaning medium, namely melt, and achieve the effects of simple start, low operating cost and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

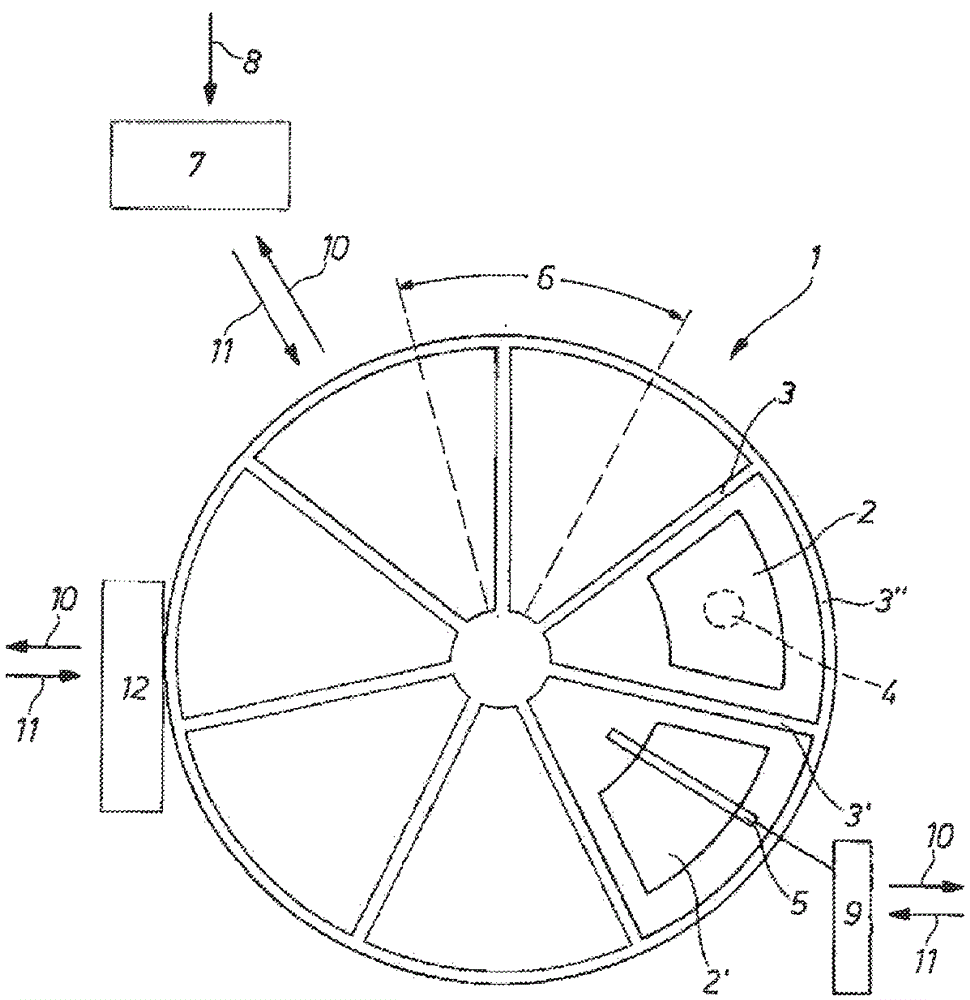

[0027] Here, the figure schematically shows a trommel 1 , here, sieves 2 and 2 ′ are shown as representative of a plurality of sieves. The screens 2 are respectively arranged between the slats 3, 3', 3" which abut against the inner wall of the trommel filter housing. The screens 2 are now located in front of the melt channel 4, while the screens 2' are located on the opposite side. The front of the cleaning slot 5 of the washing station. It can be clearly seen that the cleaning slot 5 substantially spans the size of the filter screen 2' in the radial direction, but crosses a filter screen 2' that is perpendicular to the radius in the direction perpendicular to the radial direction. The angle of extension is much smaller, but also traverses an angle smaller than the indicated rotation angle 6 in each stroke.

[0028] The control or adjustment device 7 can on the one hand pre-set parameters via the input mechanism 8, and on the other hand, provide the control or adjustment devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com