Pre-boring pressure meter, self-boring pressure meter and self-boring pressure metering equipment

A side pressure meter, self-drilling technology, applied in the field of foundation soil survey, construction, infrastructure engineering and other directions, can solve the problems of corrosive liquid entering the side pressure meter, easy failure, and poor quality of side pressure test.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088]This embodiment provides a pre-drilling side pressure instrument, which includes: a test device, a control device and an oil delivery pipe; the test device specifically includes a main body cylinder, an elastic membrane, a pressure sensor and a displacement sensor; the control device specifically includes Oil tank, oil pump, strain controller and data analyzer; where,

[0089] The oil pump is respectively connected to the oil delivery pipe and the oil tank, and is used to output the hydraulic oil in the oil tank through the oil delivery pipe or recover the hydraulic oil into the oil tank;

[0090] One end of the oil delivery pipe is connected to the oil pump, and the other end is connected to the main body cylinder, for inputting hydraulic oil into the main body cylinder, or recovering the hydraulic oil inside the main body cylinder;

[0091] A first through hole is provided on the cylinder wall of the main cylinder;

[0092] The elastic film is sheathed outside the mai...

Embodiment 2

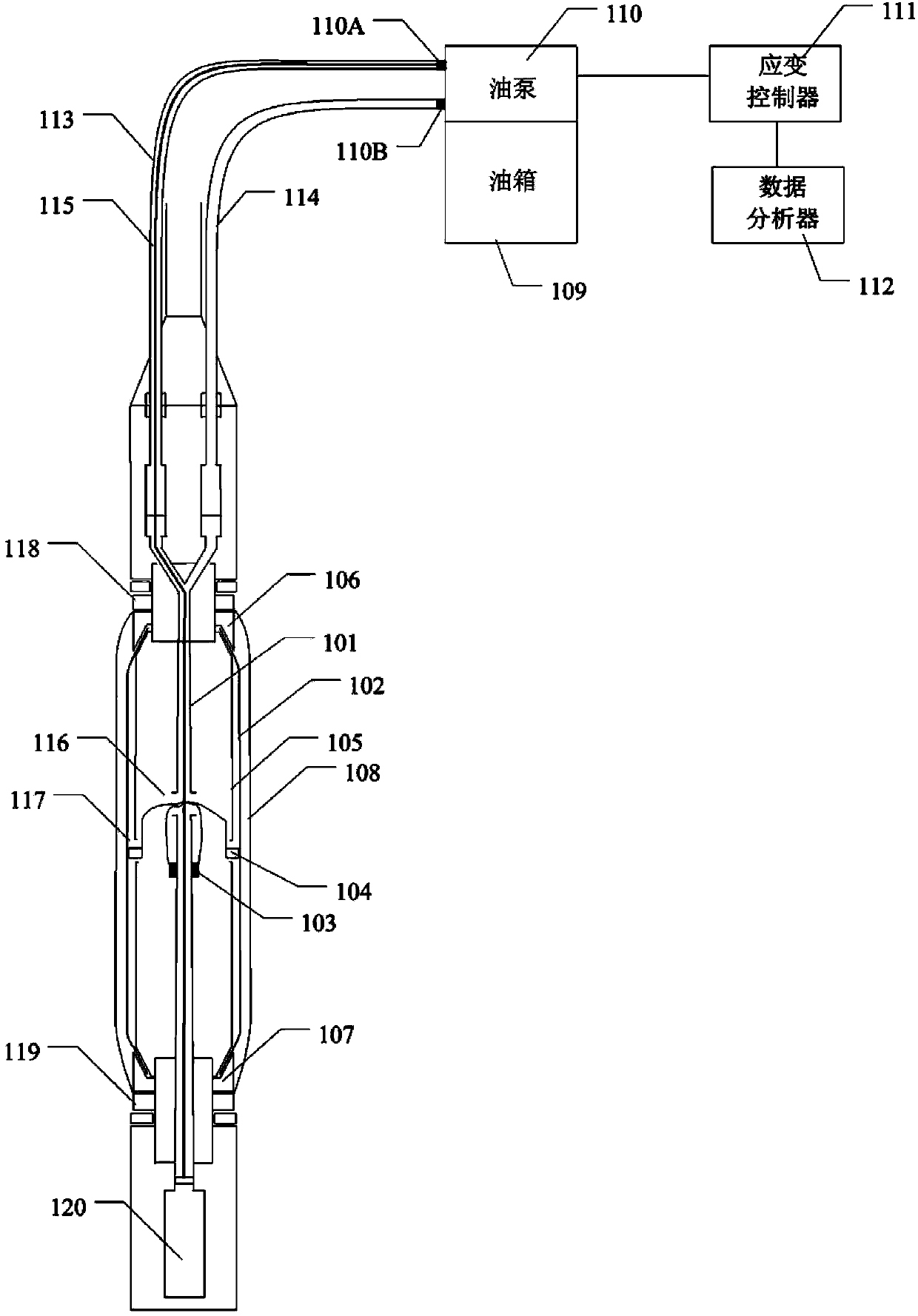

[0123] This embodiment provides a specific pre-drilling side pressure instrument, such as figure 1 As shown, the pre-drilling side pressure instrument includes: a main cylinder 101, an elastic film 102, a pressure sensor 103, a displacement sensor 104, a device compartment 105, an upper collar 106, a lower collar 107, an elastic film protective cover 108, and a fuel tank 109 , oil pump 110, strain controller 111, data analyzer 112, output oil pipe 113, recovery oil pipe 114, data line 115, upper fixing ring 118, lower fixing ring 119, electronic instrument warehouse 120; oil pump 110 specifically includes oil outlet valve 110A and Oil return valve 110B;

[0124] Among them, the main body cylinder 101, the elastic membrane 102, the pressure sensor 103, the displacement sensor 104, the device compartment 105, the upper collar 106, the lower collar 107, the elastic membrane protective sleeve 108, the upper fixing ring 118, the lower fixing ring 119 and the electronic instrument ...

Embodiment 3

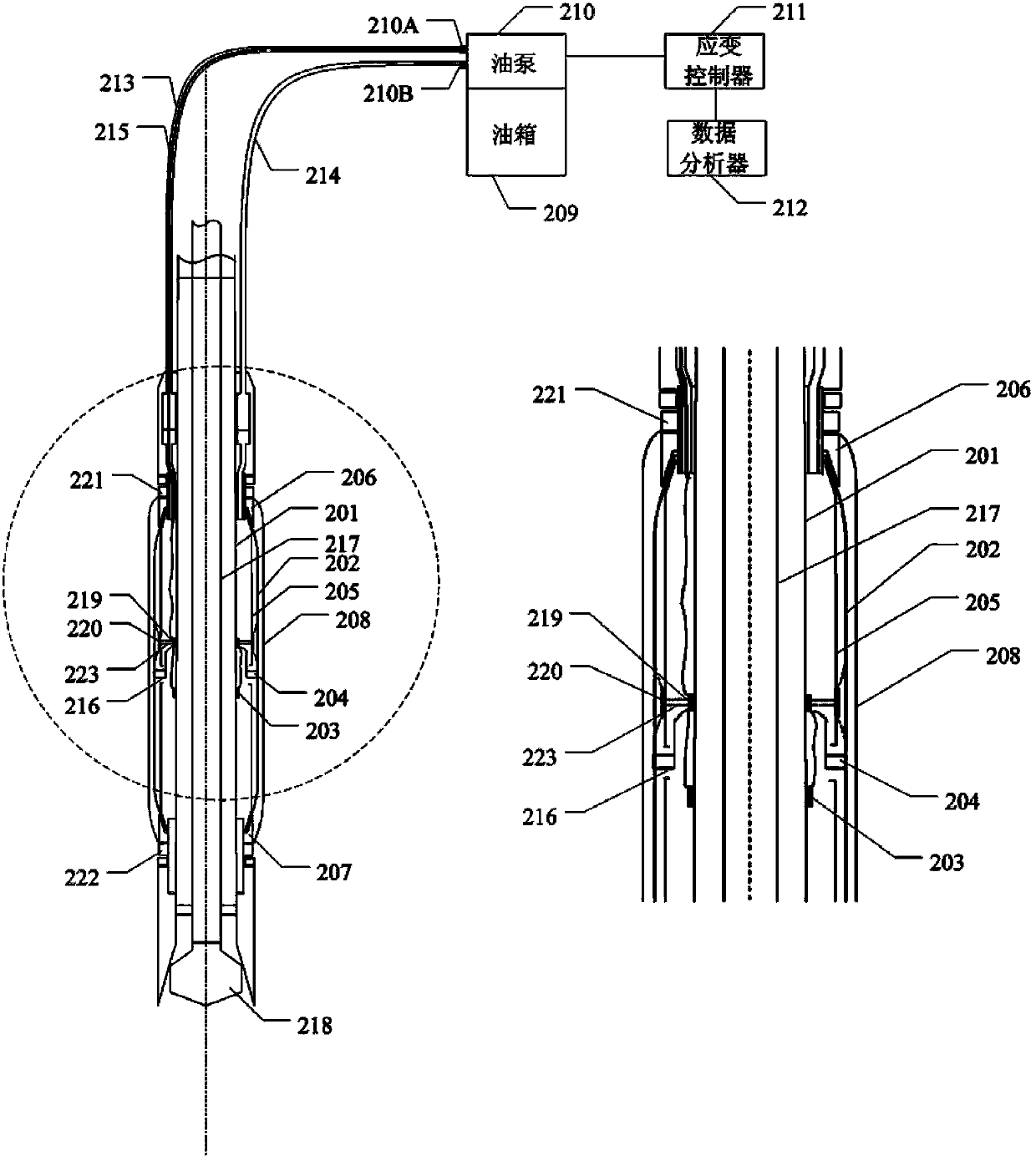

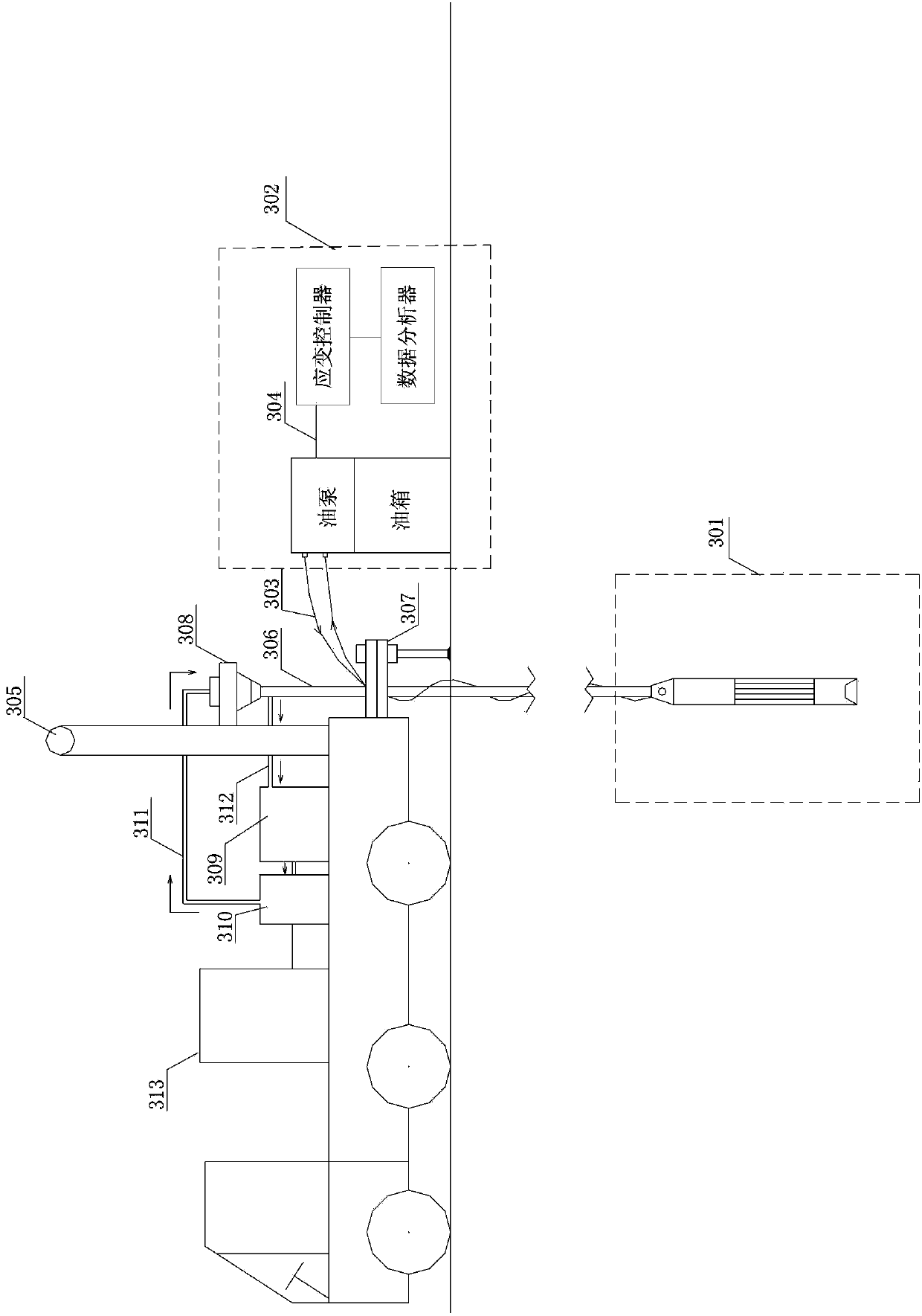

[0137] This embodiment provides a self-drilling side pressure instrument, which includes: a test device, a control device and an oil delivery pipe; the test device specifically includes an outer sleeve, an inner sleeve, a drill bit, an elastic membrane, a pressure sensor, displacement sensor, permeable stone and pore water pressure sensor; the control device specifically includes an oil tank, an oil pump, a strain controller and a data analyzer; among them,

[0138] The inner diameter of the outer sleeve is larger than the outer diameter of the inner sleeve, and is sleeved outside the inner sleeve;

[0139] The drill bit is fixedly connected to the lower end of the inner sleeve, and is used for rotary drilling driven by the inner sleeve;

[0140] The elastic film is sleeved outside the outer sleeve and forms a closed space with the wall of the outer sleeve. The elastic film expands when the closed space is filled with hydraulic oil and discharges the hydraulic oil in the close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com