Fermentation liquid compound defoaming device

A technology for defoaming device and fermentation liquid, which is applied in bioreactor/fermenter combination, biochemical cleaning device, enzymology/microbiology device, etc. Good cutting effect and the effect of eliminating foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

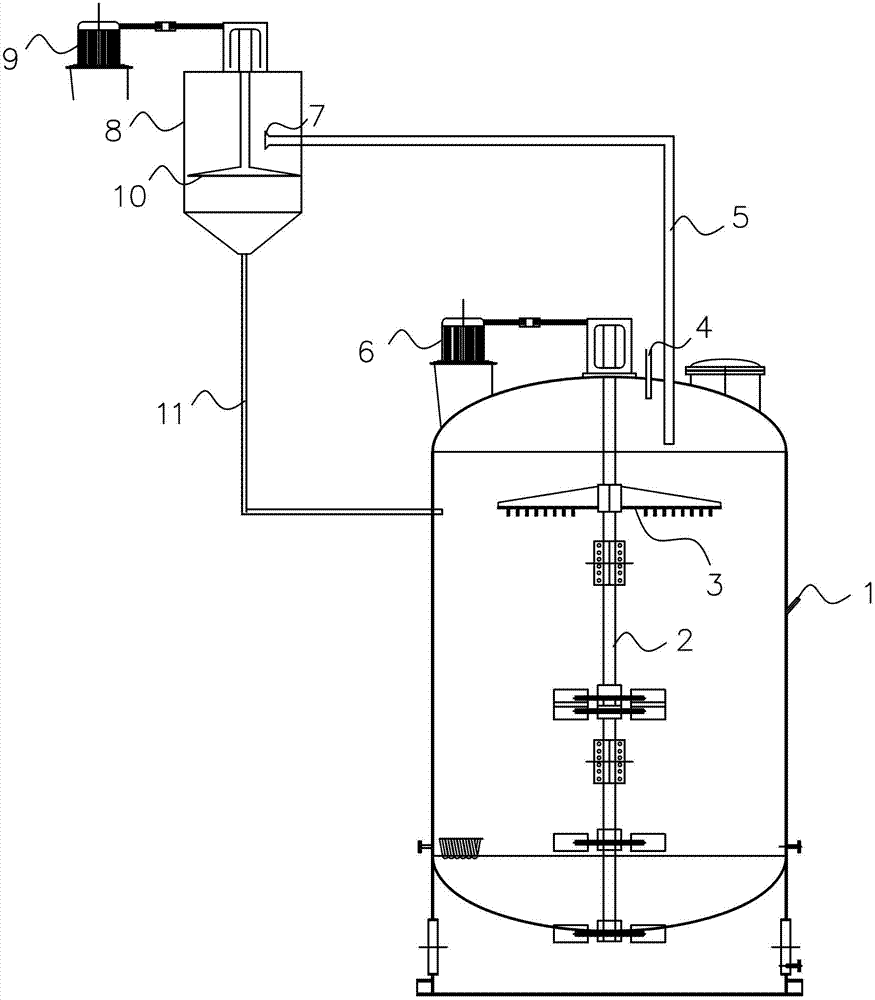

[0017] Such as figure 1 As shown, the compound defoaming device for fermented liquid includes a fermenter body 1, a stirring shaft 2 is arranged in the fermenting tank body, a rake type defoaming slurry 3 is installed on the stirring shaft, and the rake type defoaming slurry 3 is installed on the liquid surface The upper position rotates with the stirring shaft 2, and the foam is broken by rake teeth. The stirring shaft is driven 6 by a first motor, and an exhaust pipe 4 is arranged on the upper part of the fermenter body.

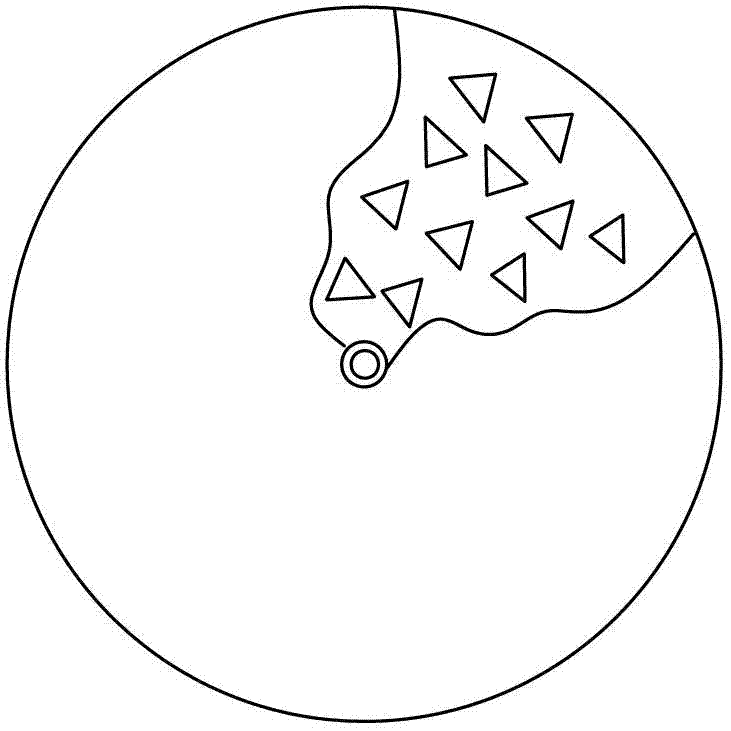

[0018] Such as figure 2 , the rake teeth 31 at the bottom of the rake defoaming slurry 3 are irregularly arranged in a triangular shape, and one corner of the rake teeth 31 is consistent with the turning direction of the stirring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com