Preparation method for nanocarbon fluid

A nanofluid and nanocarbon technology, applied in chemical instruments and methods, fibrous fillers, coatings, etc., can solve the problems of ineffective control of reactions and complex reaction processes, achieve a good reaction environment, increase -COOH content, The effect of increasing the grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

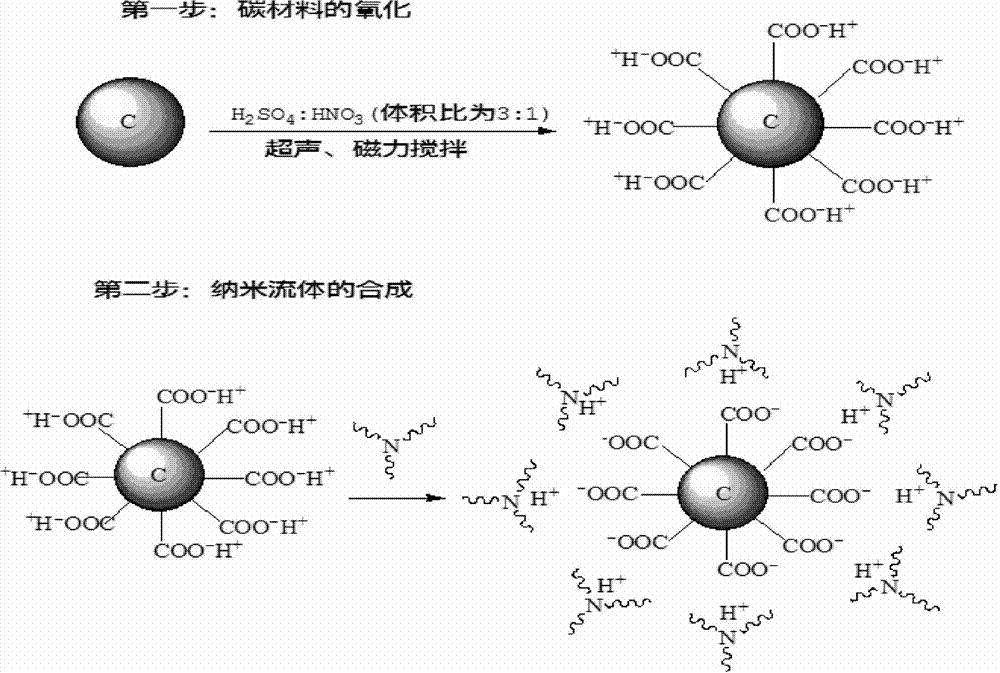

[0038] 1) Concentrate H 2 SO 4 , Concentrated HNO 3 Prepare an acidic oxidizing solution in a volume ratio of 3:1 and add it to an Erlenmeyer flask containing the original carbon black to obtain an oxidized carbon black mixed solution; ultrasonicate the mixed solution until the carbon material is completely oxidized to obtain an oxidized carbon black reaction solution; The oxidized carbon black reaction solution is dialyzed and dried to obtain oxidized carbon black particles for use.

[0039] 2) Take 0.2g of oxidized carbon black, slowly dissolve it in deionized water, magnetically stir for 2h, ultrasonic for 30min, and then magnetically stir for 24h to obtain a uniformly dispersed oxidized carbon black suspension; prepare a HCl, NaOH solution with a concentration of 0.01 mol / L, Add excess NaOH solution dropwise to the carbon oxide material suspension, react for 24 hours to obtain the alkaline carbon oxide material suspension; add HCl dropwise to the alkaline carbon oxide material...

Embodiment 2

[0043] 1) Concentrate H 2 SO 4 , Concentrated HNO 3 Prepare an acidic oxidizing solution at a volume ratio of 3:1 and add it to an Erlenmeyer flask containing original graphene to obtain a graphene oxide mixed solution; ultrasonicate the mixed solution until the graphene oxidation is complete to obtain a graphene oxide reaction solution; The graphene oxide reaction solution is dialyzed and dried to obtain graphene oxide particles for use.

[0044] 2) Take 0.2g of graphene oxide, slowly dissolve it in deionized water, magnetically stir for 2h, ultrasonic for 30min, and then magnetically stir for 24h to obtain a uniformly dispersed graphene oxide suspension; prepare a solution of HCl and NaOH with a concentration of 0.01 mol / L, Add excess NaOH solution dropwise to the graphene oxide suspension, react for 24h to obtain a basic graphene oxide suspension; add HCl dropwise to the alkaline graphene oxide suspension, measure the pH, and stop when the pH=7 Titration, calculate the content...

Embodiment 3

[0048] 1) Concentrate H 2 SO 4 , Concentrated HNO 3 According to the volume ratio of 3:1, it is made into an acidic oxidizing solution, which is added to an Erlenmeyer flask containing original nano graphite to obtain a graphite oxide mixed solution; the mixed solution is sonicated until the graphite is completely oxidized to obtain a graphite oxide reaction solution; the graphite oxide is reacted The solution is dialyzed and dried to obtain graphite oxide particles for use.

[0049] 2) Take 0.2g graphite oxide, slowly dissolve it in deionized water, magnetically stir for 2h, ultrasonic for 30min, and then magnetically stir for 24h to obtain a uniformly dispersed graphite oxide suspension; prepare a 0.01 mol / L HCl, NaOH solution, and remove excess The NaOH solution was added dropwise to the graphite oxide suspension and reacted for 24 hours to obtain an alkaline graphite oxide suspension; HCl was added dropwise to the alkaline carbon oxide material suspension, the pH was measured,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com