Repair material for bituminous pavement pot holes and method for preparing same

A technology of asphalt pavement and repair materials, which is applied in the field of materials, can solve the problems of long operation time, slow cooling speed of mixture, and large energy consumption, and achieve the effects of improving strength and rigidity, simple construction technology, and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050]

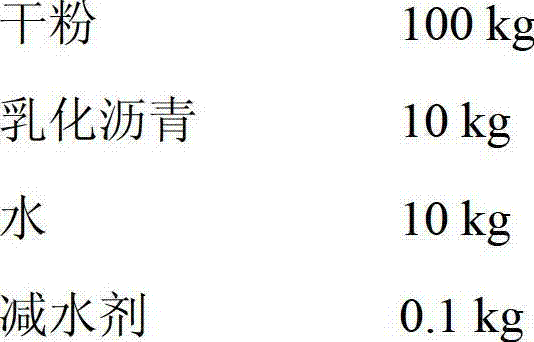

[0051] Wherein, the dry powder is formed by mixing and stirring the following materials by mass:

[0052]

[0053] Accurately weigh each material according to the above mixing ratio, first put the dry powder, water reducer and water into the mixer and stir at a speed of 200r / min for 60s, then put the emulsified asphalt into the mixer and stir at a speed of 200r / min for 30s, and finally Stir at a speed of 400r / min for 180s. The properties of the prepared mortar materials were tested, and the results are shown in Table 1.

Embodiment 2

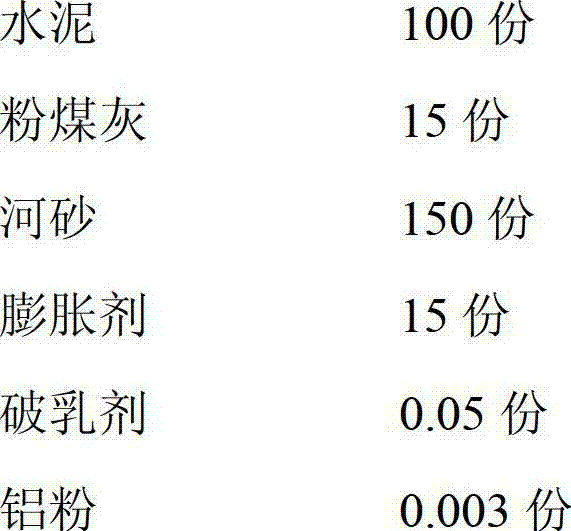

[0055]

[0056] Wherein, the dry powder is formed by mixing and stirring the following materials by mass:

[0057]

[0058]

[0059] Accurately weigh various components according to the above mixing ratio, first put the dry powder, water reducer and water into the mixer and stir at a speed of 200r / min for 60s, then put the emulsified asphalt into the mixer and stir at a speed of 200r / min for 30s, Finally, stir at a speed of 400r / min for 180s. The properties of the prepared mortar materials were tested, and the results are shown in Table 1.

Embodiment 3

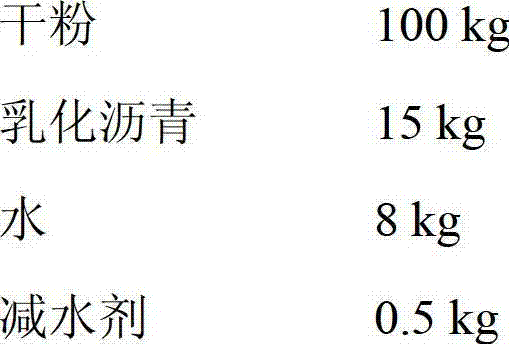

[0061]

[0062] Wherein, the dry powder is formed by mixing and stirring the following materials by mass:

[0063]

[0064]Accurately weigh various components according to the above mixing ratio, first put the dry powder, water reducer and water into the mixer and stir at a speed of 200r / min for 60s, then put the emulsified asphalt into the mixer and stir at a speed of 200r / min for 30s, Finally, stir at a speed of 400r / min for 180s. The properties of the prepared mortar materials were tested, and the results are shown in Table 1.

[0065] Table 1 performance test results

[0066]

[0067] It can be seen from the above table that the early strength and elastic modulus of repair materials are also different with different emulsified asphalt content. As the amount of emulsified asphalt increases, the strength of the repair material decreases, and the modulus of elasticity decreases accordingly, which can be used for pothole repair on different asphalt pavements. In ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com