Method for treating ammonia nitrogen in tungsten smelting by using extraction absorption

An extraction and ammonia nitrogen technology, which is applied in the direction of extraction water/sewage treatment, separation method, metallurgical wastewater treatment, etc., can solve the problems of high cost of evaporation recovery, low recovery rate, and low recovery rate of ammonia nitrogen.

Active Publication Date: 2013-02-13

XIAMEN TUNGSTEN

View PDF7 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] At present, in tungsten smelting, the evaporation and crystallization method is used to recover ammonia to produce ammonium chloride, so as to realize the recycling of ammonia nitrogen. The existing technology has the disadvantages of low recovery rate of ammonia nitrogen, large energy consumption of evaporation and crystallization, and high cost.

Low recovery rate will inevitably lead to poor working environment and difficult discharge of wastewater

At the same time, as the price of oil continues to rise, the cost of evaporation recovery will also become higher and higher

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

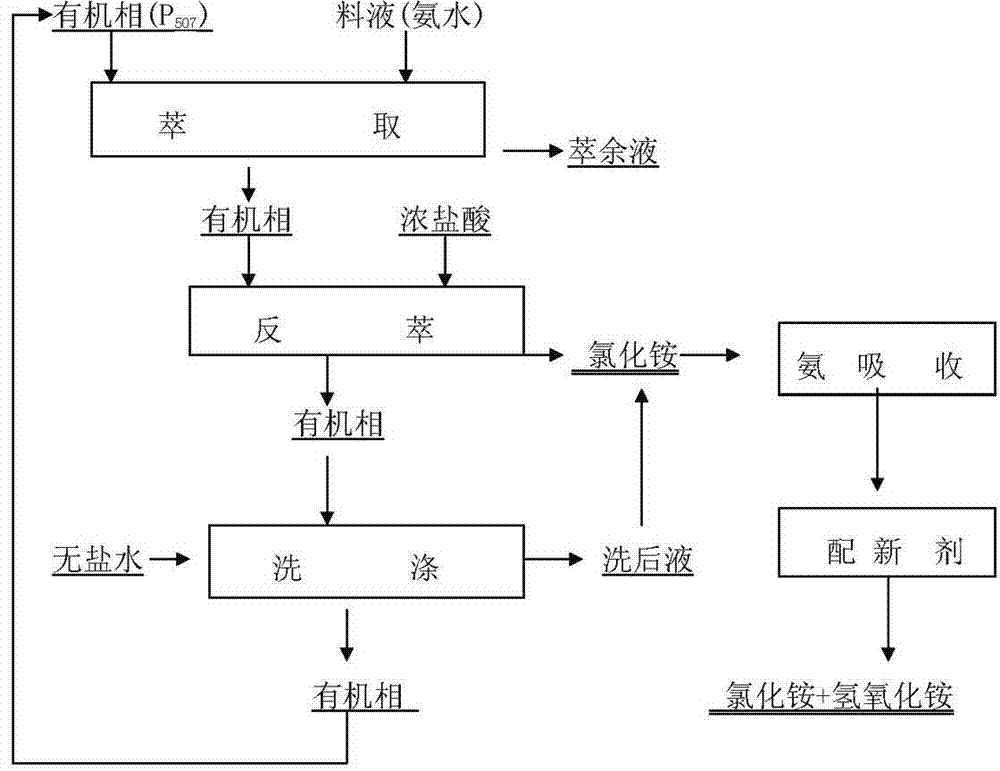

[0015] With reference to Fig. 1, Fig. 2 and Fig. 3, principle analysis of the present invention:

[0016] One, the choice of extractant

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for treating ammonia nitrogen in tungsten smelting by using extraction absorption. According to the method, the recovery rate of the ammonia nitrogen is further improved, and the working environment is improved and the production cost is decreased. Primary extraction: organic phase extractants are added to weak aqua ammonia recycled by evaporation to perform extraction to obtain ammonium ions NH4+, and free water and hydroxide ions in ammonia water enter extraction residual liquid water phases; secondary extraction: industrial concentrated hydrochloric acids are added in extracted organic phases, heavy phases after reverse extraction are ammonium chloride at the bottom; light phases containing P507 organic phases enter a next circle for extraction after washing; an reverse extraction solution of an ammonium chloride solution is subjected to ammonia absorption; ammonia water with a concentration of 110g / l returns to a tungsten smelting departure and transfer procedure to serve as an analyzing agent; and final washing: salt-free water is added to organic phases after reverse extraction, organic phase residual ammonium chloride is guaranteed to be discharged as far as possible, an after-washing solution is an ammonium chloride solution, the ammonium chloride solution and the reverse extraction of the last step are subjected to ammonia absorption, and an organic phase extraction agent P507 after washing enters a next circle for usage. The method further improves the ammonia nitrogen recovery rate, the work environment is improved, and the production cost is reduced.

Description

technical field [0001] The invention relates to the application of a novel extraction and absorption combined technology in the treatment of ammonia nitrogen in tungsten smelting. Background technique [0002] At present, in tungsten smelting, the evaporation and crystallization method is used to recover ammonia to produce ammonium chloride, so as to realize the recycling of ammonia nitrogen. The existing technology has the disadvantages of low recovery rate of ammonia nitrogen, large energy consumption and high cost of evaporation and crystallization. A low recovery rate will inevitably lead to a poor working environment and difficult discharge of wastewater. At the same time, as the price of oil continues to rise, the cost of evaporation recovery will also become higher and higher. Therefore, it is of great significance to develop a recovery process with low energy consumption to replace the current evaporation crystallization process. Contents of the invention [0003...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C02F1/26B01D53/18C02F101/16C02F103/16

Inventor 黄文璞孟笑

Owner XIAMEN TUNGSTEN

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com