Novel process for recycling tail gas generated in polycrystalline silicon production

A new process, polysilicon technology, applied in the field of chemical engineering, can solve the problems of complex tail gas separation process, high equipment investment cost, high energy consumption, etc., and achieve the effects of stable content of each component of tail gas, reduced equipment investment, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

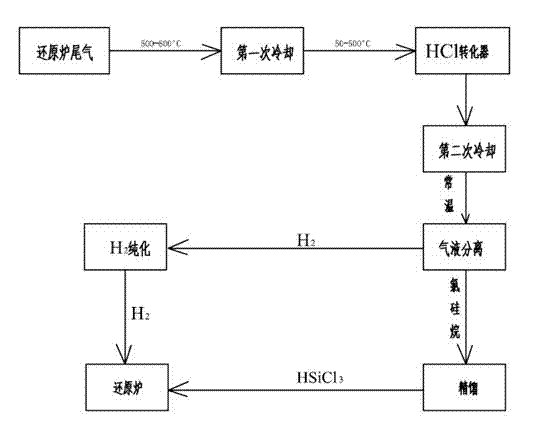

[0028] A new process for recovering the tail gas produced by polysilicon production, the components of the tail gas include H 2 , HCl, HSiCl 3 、SiCl 4 、H 2 SiCl 2 , it is characterized in that described new process comprises the following steps:

[0029] Cooling step: the tail gas output from the reduction furnace with a temperature of 500~600°C is cooled to 300°C for the first time, and then sent to the HCl converter;

[0030] Reaction steps: HCl and HSiCl in the HCl converter 3 、H 2 SiCl 2 The reaction completely generates the corresponding chlorosilane;

[0031] Gas-liquid separation step: After the tail gas from the HCl converter is cooled for the second time, the temperature of the tail gas drops to normal temperature, and then SiCl 4 Refrigerated liquid is sprayed, for H 2 Gas-liquid separation with chlorosilane;

[0032] h 2 Purification steps: the H 2 After being adsorbed and removed by the adsorption column, it is recovered and treated;

[0033] with H 2...

Embodiment 2

[0036] A new process for recovering the tail gas produced by polysilicon production, the components of the tail gas include H 2 , HCl, HSiCl 3 、SiCl4 、H 2 SiCl 2 , the new process comprises the following steps:

[0037] Cooling step: the tail gas output from the reduction furnace with a temperature of 500-600°C is cooled to 50°C for the first time through a heat exchanger and then sent to the fixed-bed reactor;

[0038] Reaction steps: In a fixed-bed reactor equipped with a polymer cross-linked resin catalyst, HCl and HSiCl 3 、H 2 SiCl 2 The reaction completely generates the corresponding chlorosilane; the reaction temperature is 50°C, the reaction pressure is 2.0MPa, and the HCl content in the tail gas output from the fixed bed reactor is less than 0.1%;

[0039] Gas-liquid separation step: the tail gas output from the fixed-bed reactor is cooled to normal temperature for the second time through a heat exchanger, and then SiCl 4 Refrigerated liquid is sprayed, for H 2...

Embodiment 3

[0044] A new process for recovering the tail gas produced by polysilicon production, the components of the tail gas include H 2 , HCl, HSiCl 3 、SiCl 4 、H 2 SiCl 2 , the new process comprises the following steps:

[0045] Cooling step: the tail gas output from the reduction furnace with a temperature of 500-600°C is cooled to 100°C for the first time through a heat exchanger and then sent to the fluidized bed reactor;

[0046] Reaction steps: In a fluidized bed reactor equipped with a copper molecular sieve catalyst, HCl and HSiCl 3 、H 2 SiCl 2 The reaction completely generates the corresponding chlorosilane; the reaction temperature is 100°C, the reaction pressure is 0.9 MPa, and the HCl content in the tail gas output from the fluidized bed reactor is less than 0.1%;

[0047] Gas-liquid separation step: the tail gas output from the fluidized bed reactor is cooled to normal temperature for the second time through a heat exchanger, and then SiCl 4 Refrigerated liquid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com