High-density nano electrode array and preparation method thereof

A nano-electrode array and nano-array technology, applied in the field of micromachining, can solve the problems of limiting industrialization and application, poor uniformity and controllability, poor process compatibility, etc., and achieves excellent uniformity, high controllability of spacing and height , Efficient and fast cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

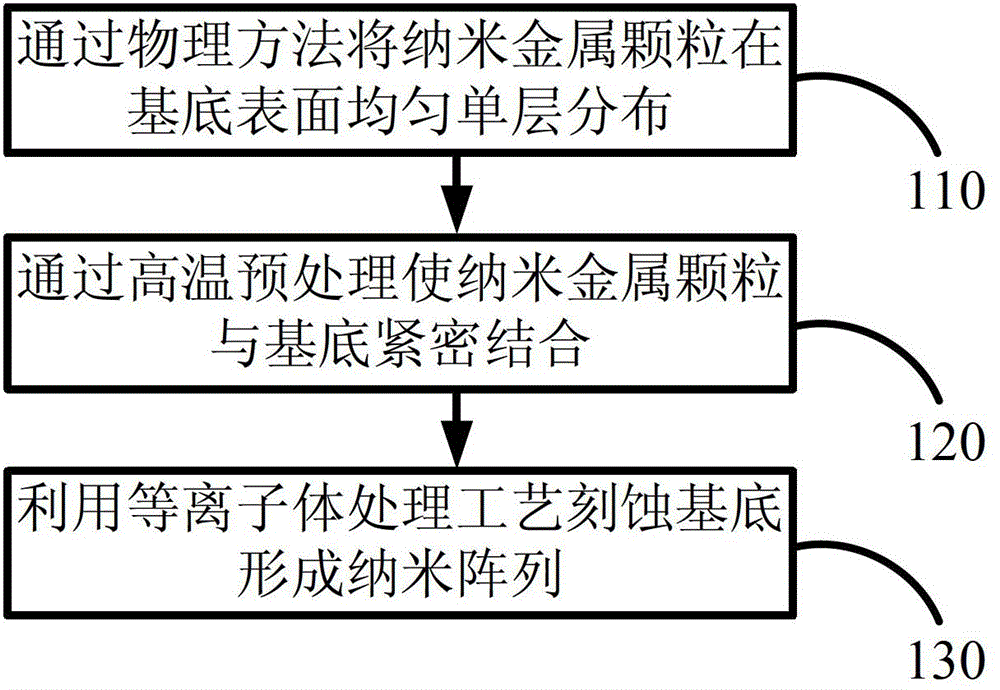

[0026] In order to make the above objects, features and advantages of the present invention more comprehensible, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0027] The specific steps of the high-density nano-electrode array provided by the present invention and its preparation method are described below in conjunction with the accompanying drawings.

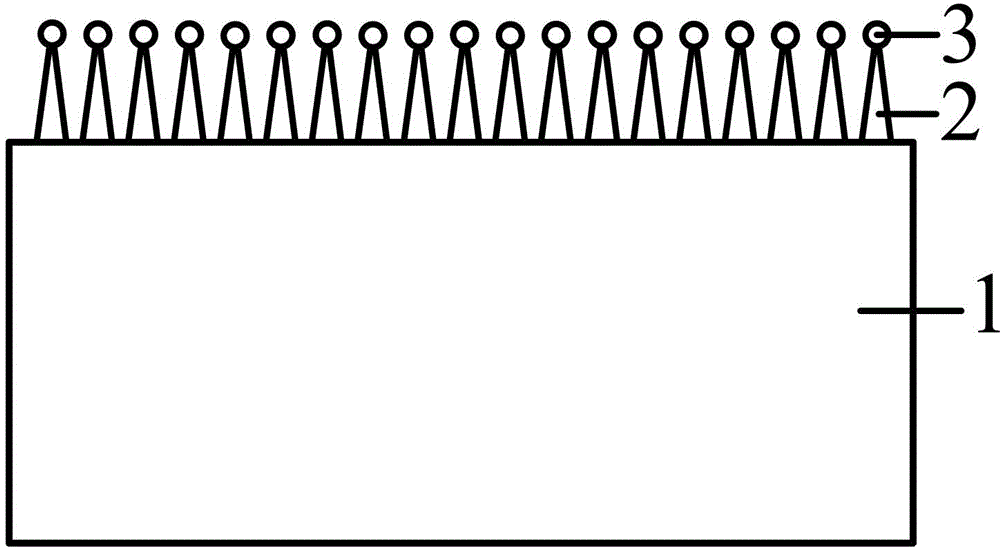

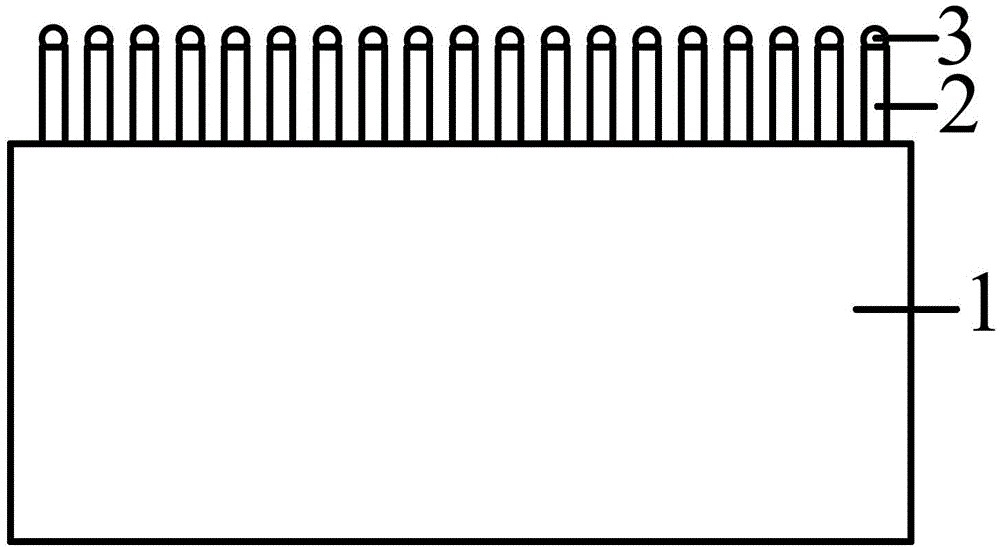

[0028] Referring to Figure 1, Figure 1(a) and Figure 1(b) are schematic diagrams of the structure of the high-density nano-electrode array of the present invention, and the nano-arrays are respectively: Figure 1(a) the nano-array is cone-shaped, Figure 1(b) Arrays are columnar.

[0029] Among them, the substrate 1 is a metal or semiconductor with good conductivity, with a thickness of 20 μm-2000 μm. The metal material is such as Au, Ag, Al, Ti, Pt, W, Cr, etc., and the semiconductor material is such as Si an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com