Feed divider

A technology of material distribution device and material distribution plate, which is applied in the direction of transportation, packaging, and slideway, etc., can solve the problem that the material distribution valve cannot reach the interval switching channel to transport fragile granular materials, and achieve the best comprehensive utilization effect and use performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

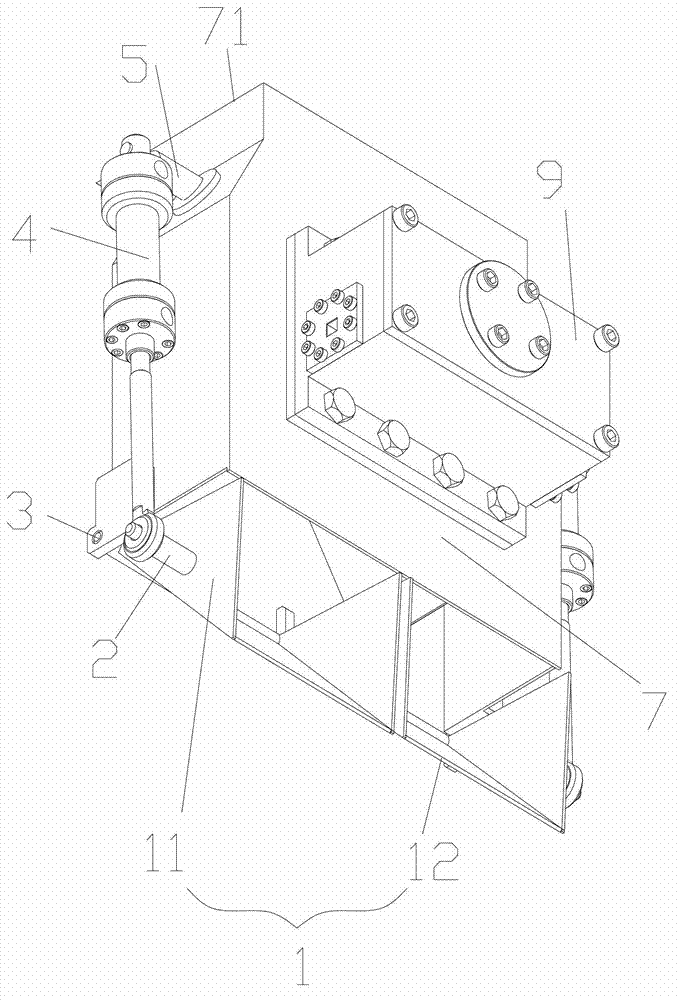

[0029] Such as Figure 1 to Figure 3 As shown, the material distributing device according to the embodiment of the present invention includes: an upper box body 7 , a lower box body 1 and a material distribution plate 6 .

[0030] Upper casing 7, described upper casing 7 has feed inlet 71, discharge outlet 73 (see Figure 5 ) and an inner cavity 70 between the inlet and the outlet.

[0031] The lower box body 1 is connected below the upper box body 7, and the lower box body 1 is provided with two independent channels communicating with the inner cavity, which are respectively the first channel and the second channel, such as figure 2 and image 3 As shown, the first channel is the part of the granular material channel A passi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com