Cardboard creasing machine for navel orange packaging

A technology of creasing machine and paper shell, applied in packaging, transportation and packaging, papermaking and other directions, can solve the problems of low degree of automation, waste of materials, low efficiency, etc., and achieve the effect of improving utilization rate and preventing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

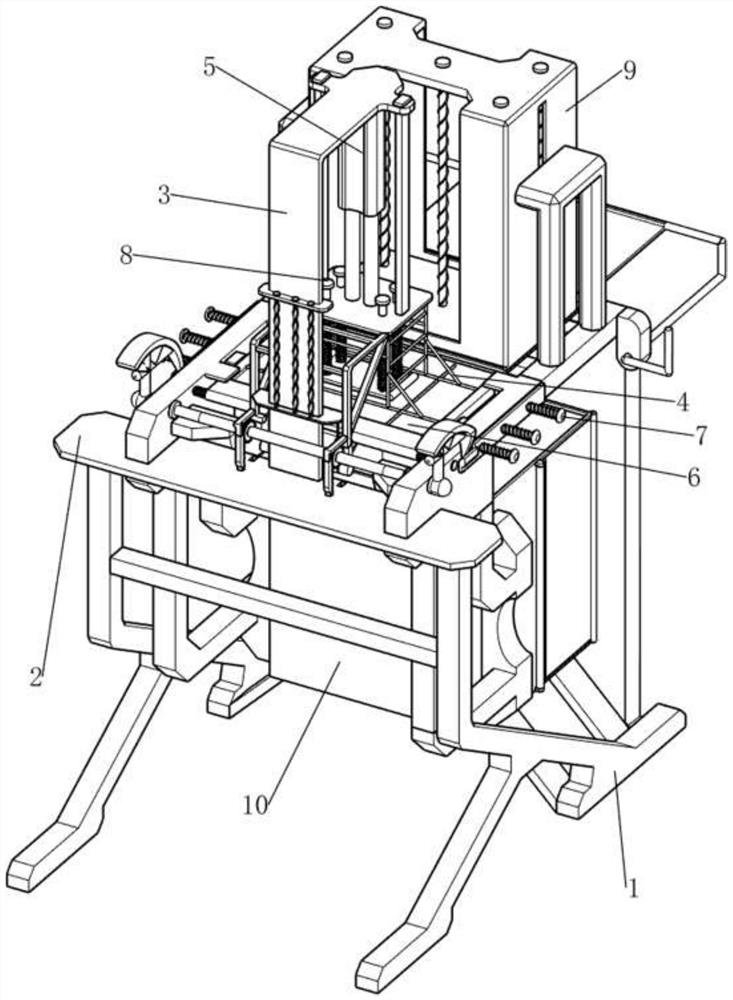

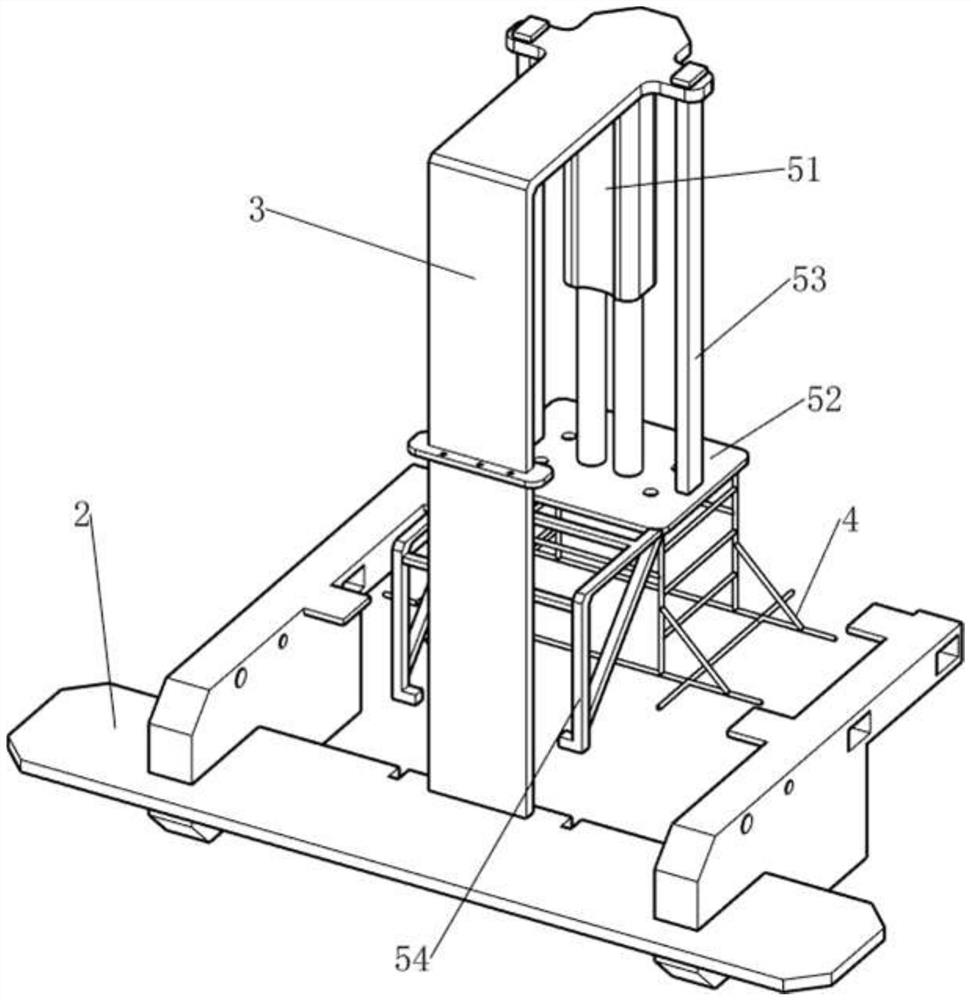

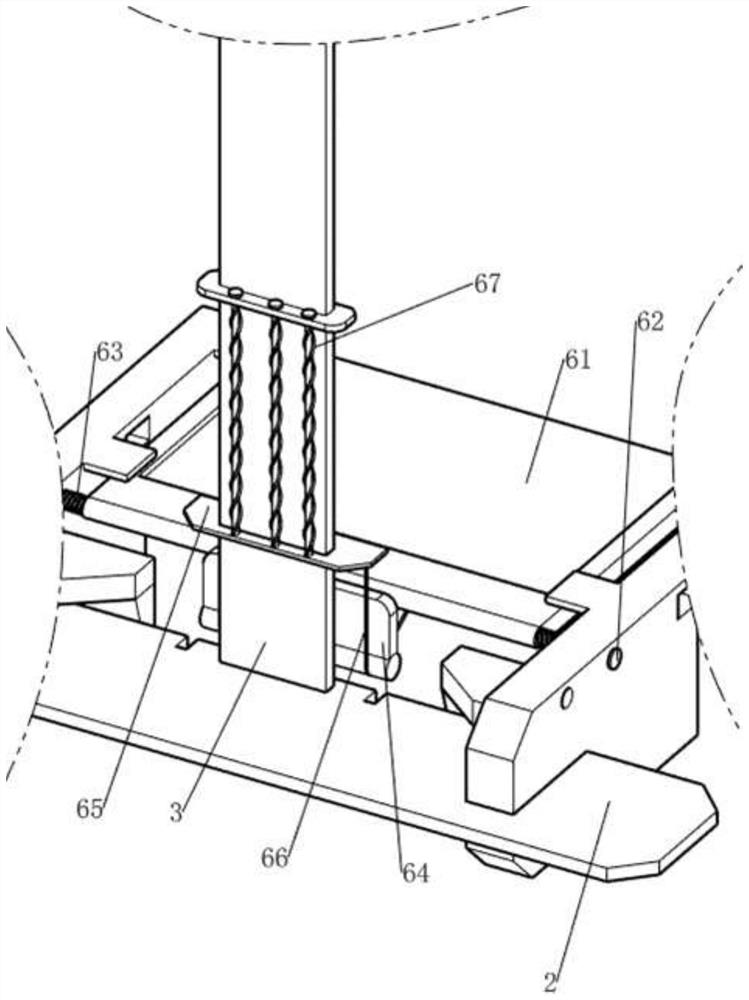

[0030] Such as Figure 1-7 A carton creasing machine shown for navel orange packaging includes support legs 1, connecting table 2, fixing plate 3, thin rod frame 4, pressing mechanism 5, cylinder 51, connecting plate 52, sliding square Rod 53, pull frame 54, blanking mechanism 6, bearing platform 61, connecting shaft 62, torsion spring 63, limit block 64, slide plate 65, string 66, compression spring 67, limit mechanism 7, rotating rod 71, Full gear 72, rising rack 73, rotating plate 74, fixed block 75, round head rod 76, first return spring 77, pressing mechanism 8, round head plate 81, connecting round rod 82, second return spring 83, upper Material mechanism 9, extension frame 91, material holding frame 92, lower pressing plate 93, contraction spring 94, pushing plate 95, pull rod 96, support rod 97, material receiving mechanism 10, fixed frame 101,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap