Caking treatment device for modified starch production

A processing device and modified starch technology, which is applied in grain processing, application, solid separation, etc., can solve the problems of incomplete crushing, high cost, time-consuming and laborious, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

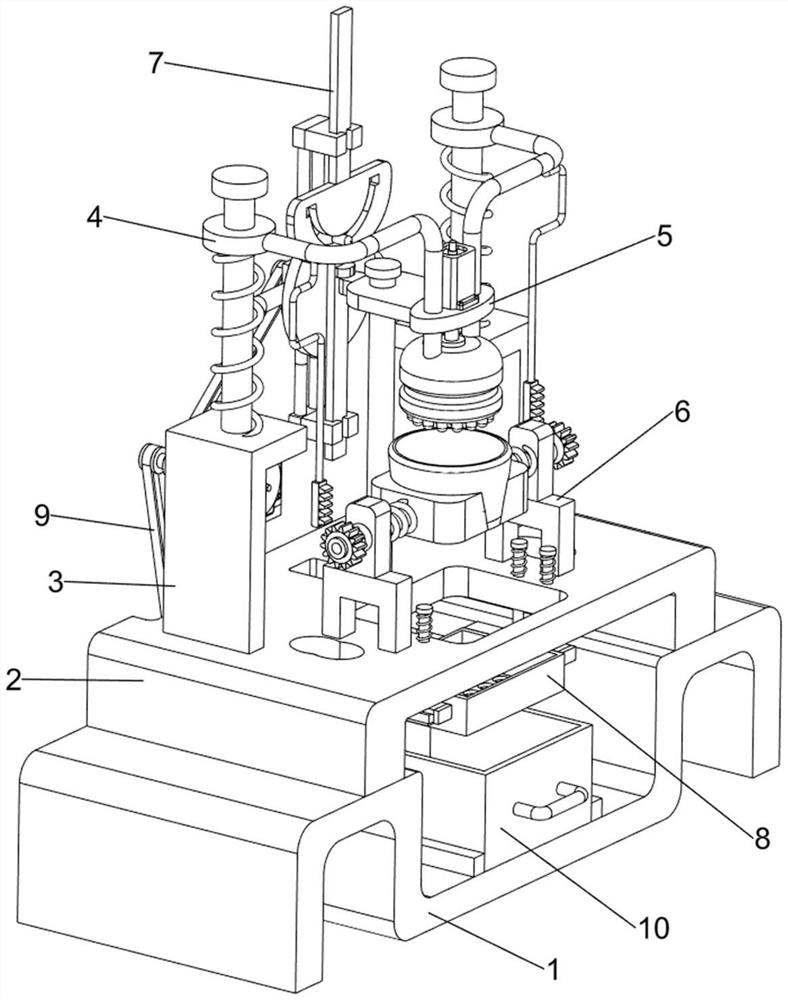

[0081] A kind of agglomeration treatment device for modified starch production, such as figure 1 As shown, it includes a bottom plate 1, a workbench 2, a mounting frame 3, a pressing mechanism 4, a rotating mechanism 5, and a feeding mechanism 6. Frame 3, the top of mounting frame 3 is provided with pressing mechanism 4, and the top of workbench 2 is provided with rotating mechanism 5, and rotating mechanism 5 is connected with pressing mechanism 4, and the top of workbench 2 is provided with unloading mechanism 6, and unloading mechanism 6 is connected with The rotating mechanism 5 cooperates, and the blanking mechanism 6 is connected with the pressing mechanism 4 .

[0082] Manual processing is time-consuming, costly, and incompletely crushed. This equipment can automatically process the raw material of agglomerated modified starch, which saves time and effort, and has low cost and high crushing rate. The raw material of agglomerated modified starch, then make the rotating ...

Embodiment 2

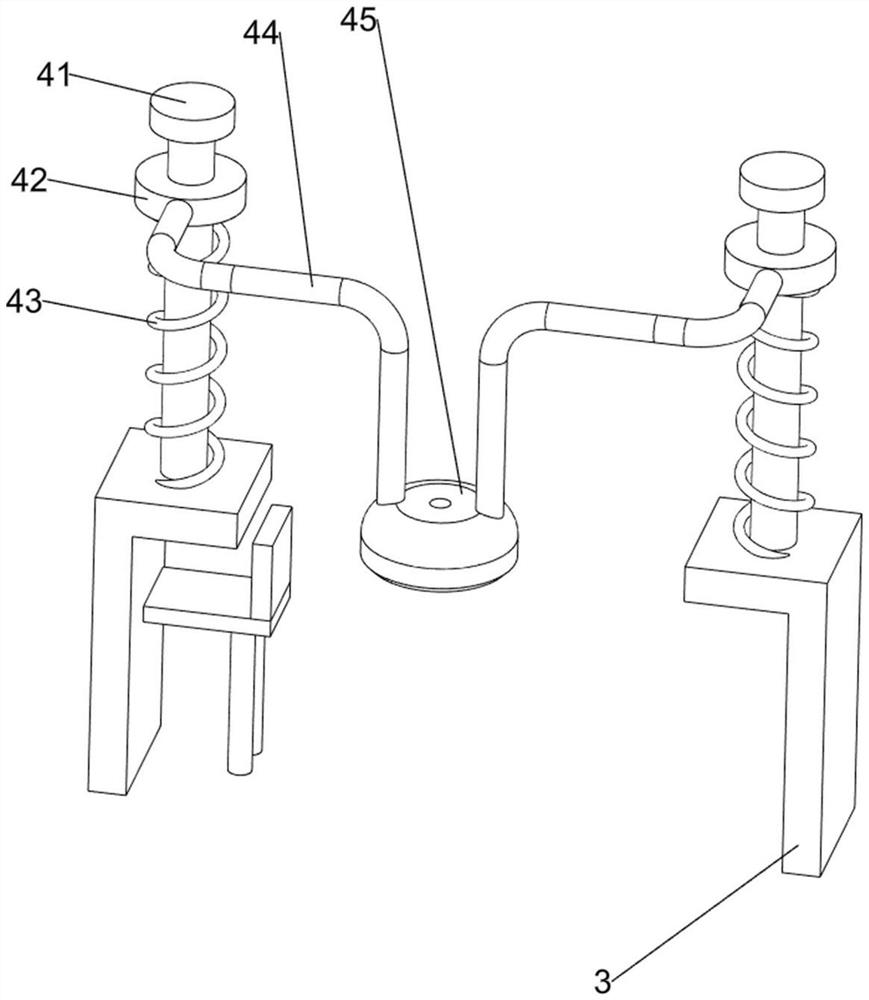

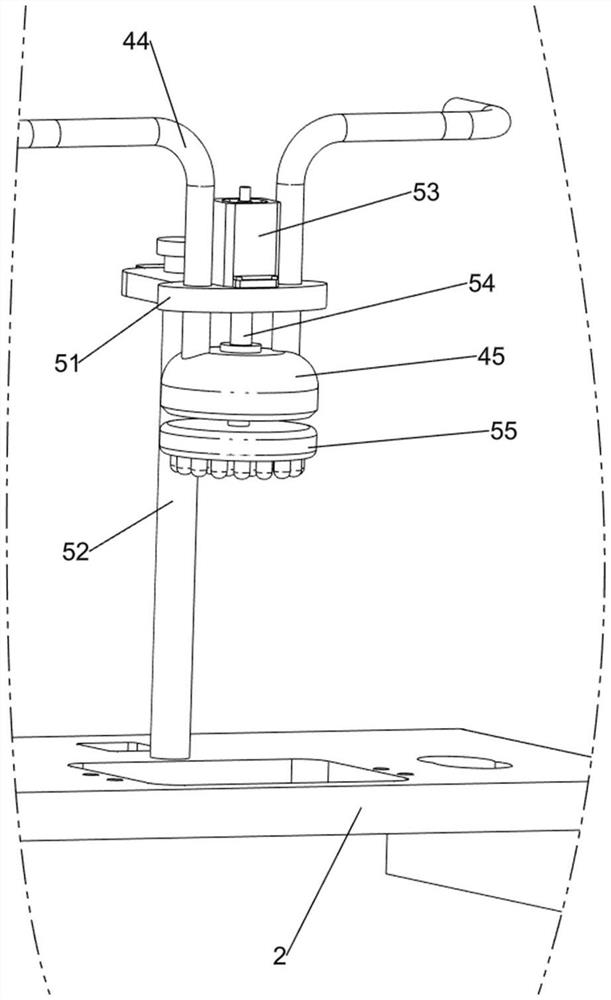

[0084] On the basis of Example 1, such as figure 2 , image 3 and Figure 4 As shown, the pressing mechanism 4 includes a first sliding rod 41, a movable block 42, a pressure spring I43, a first connecting rod 44 and a pressure block 45, and the tops of the mounting brackets 3 on the left and right sides are provided with a first sliding rod 41, The first sliding rods 41 on the left and right sides are all slidably provided with a movable block 42, and the first sliding rods 41 on the left and right sides are all wound with a pressure spring I43, the top of the pressure spring I43 is connected with the movable block 42, and the bottom of the pressure spring I43 Connected with the mounting frame 3 , the front sides of the movable blocks 42 on the left and right sides are provided with first connecting rods 44 , and the bottoms of the first connecting rods 44 on the left and right sides are connected with a pressure block 45 .

[0085] People manually slide the movable block ...

Embodiment 3

[0091] On the basis of Example 2, such as figure 1 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, a reciprocating mechanism 7 is also included. The top of the workbench 2 is provided with a reciprocating mechanism 7. The reciprocating mechanism 7 is connected with the mounting frame 3 on the left side. The reciprocating mechanism 7 cooperates with the first connecting block 51. The reciprocating mechanism 7 includes a second Motor 71, the third transmission shaft 72, belt assembly I73, the fourth transmission shaft 74, the first support frame 75, the rotating disk 76 and the sliding sleeve 77; A third drive shaft 72 is provided on the output shaft of the workbench 2, a first support frame 75 is provided at the top rear of the workbench 2, and a fourth drive shaft 74 is arranged on the inner side of the middle part of the first support frame 75, and the fourth drive shaft 74 passes through Through the first support frame 75, a belt assembly I73 is connected bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com