Undersize water treatment process for desliming screen

A treatment process and sieve water technology, applied in the direction of solid separation, etc., can solve the problems of loss of clean coal, inability to recover coarse particles, concentrate ore entering tailings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

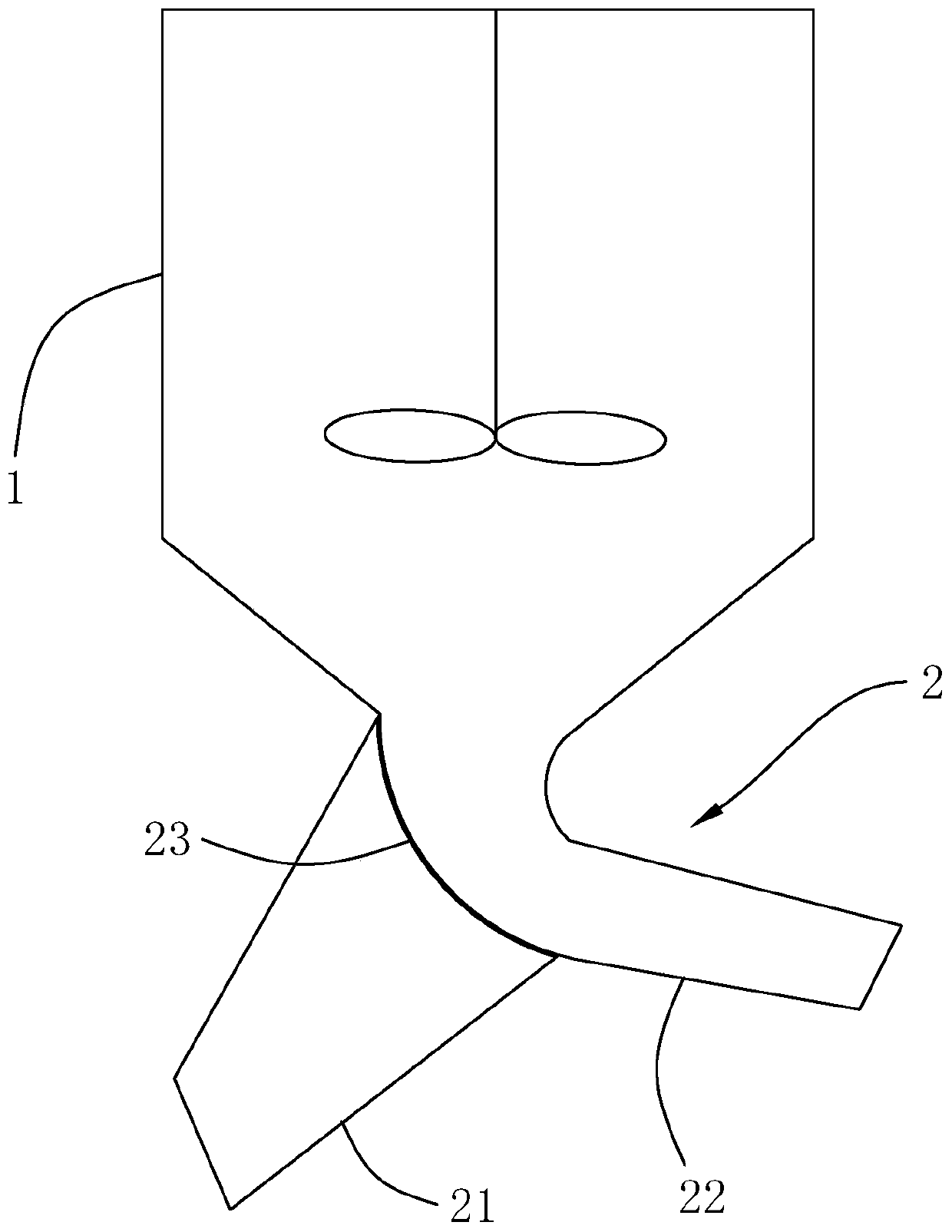

[0035] Embodiment one: a kind of desliming sieve water treatment process, such as figure 1 shown, including the following steps:

[0036] a. Screening: The three-product cyclone separates the clean coal through the de-mediation sieve, and after the de-mediation section of the de-mediation sieve is sorted by the magnetic separator, the magnetic separation tailings enter the clean coal magnetic separation tailings barrel, and then pass through the pump Drive into the clean coal hydrocyclone group, and the bottom flow passes through the chute to the desilting screen;

[0037] b. TBS screening: the coal slime under the raw coal desliming screen passes through the slime bucket, and then is pumped into the coal slime hydrocyclone group. After the bottom flow is sorted by TBS, the overflow of TBS flows into the TBS concentrate bucket, and then pumped into it. TBS concentrate hydrocyclone group separation, the bottom flow passes through the chute to the desilting screen;

[0038] ...

Embodiment 2

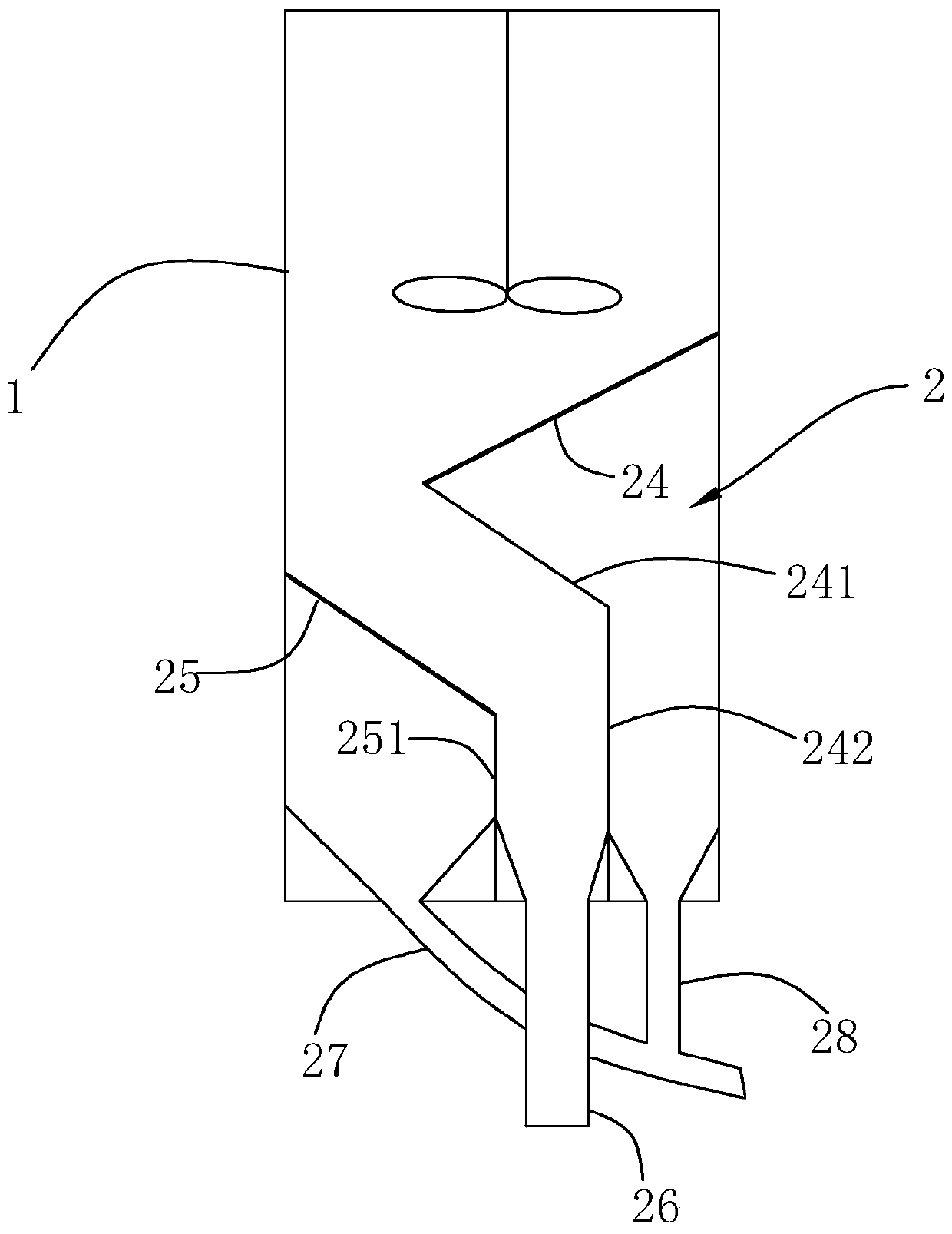

[0041] Embodiment two: if figure 2As shown, the difference between the present embodiment and the previous embodiment is that the material distribution assembly 2, the material distribution assembly 2 includes a primary screen 24 and a screening screen 25 located inside the flotation bucket 1, and the primary screen 24 is positioned at the sieve. Above the sub-net 25, the primary selection net 24 and the screening net 25 are all inclined to be arranged, and the direction of inclination is opposite, so that the sailor under the sieve first falls on the primary selection net 24 for screening, and then flows from the primary selection net 24 to The sieving net 25 is screened again; the inclined lower end of the primary selection net 24 is fixedly connected with an inclined material guide plate 241, and the inclined direction and angle of the material guide plate 241 are all the same as the screening net 25, and the inclined lower end of the material guide plate 241 The vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com