Link mechanism for opening and closing die set and lifting bottom die of bottle blowing machine

A technology of linkage mechanism and bottle blowing machine, which is applied in the field of linkage mechanism, can solve problems such as space occupation, noise pollution, and cracking of rollers, and achieve the effects of improving space utilization, ensuring matching accuracy, and reducing noise intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

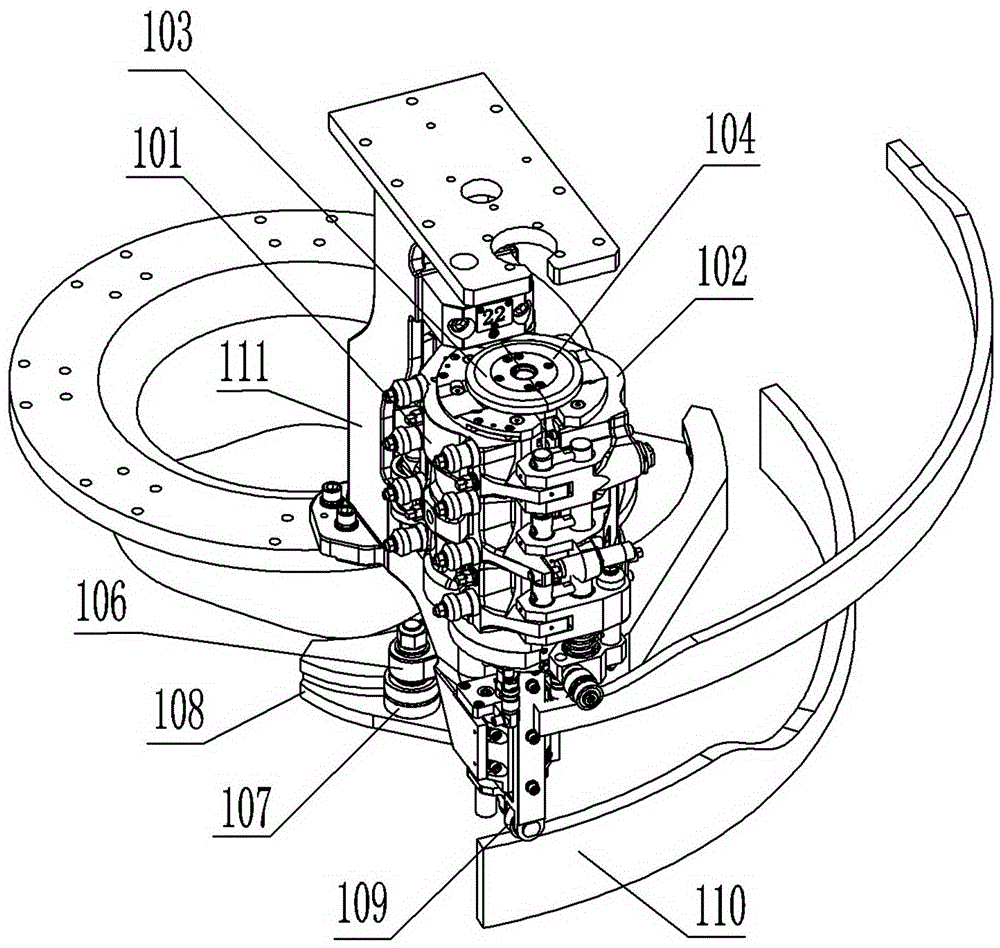

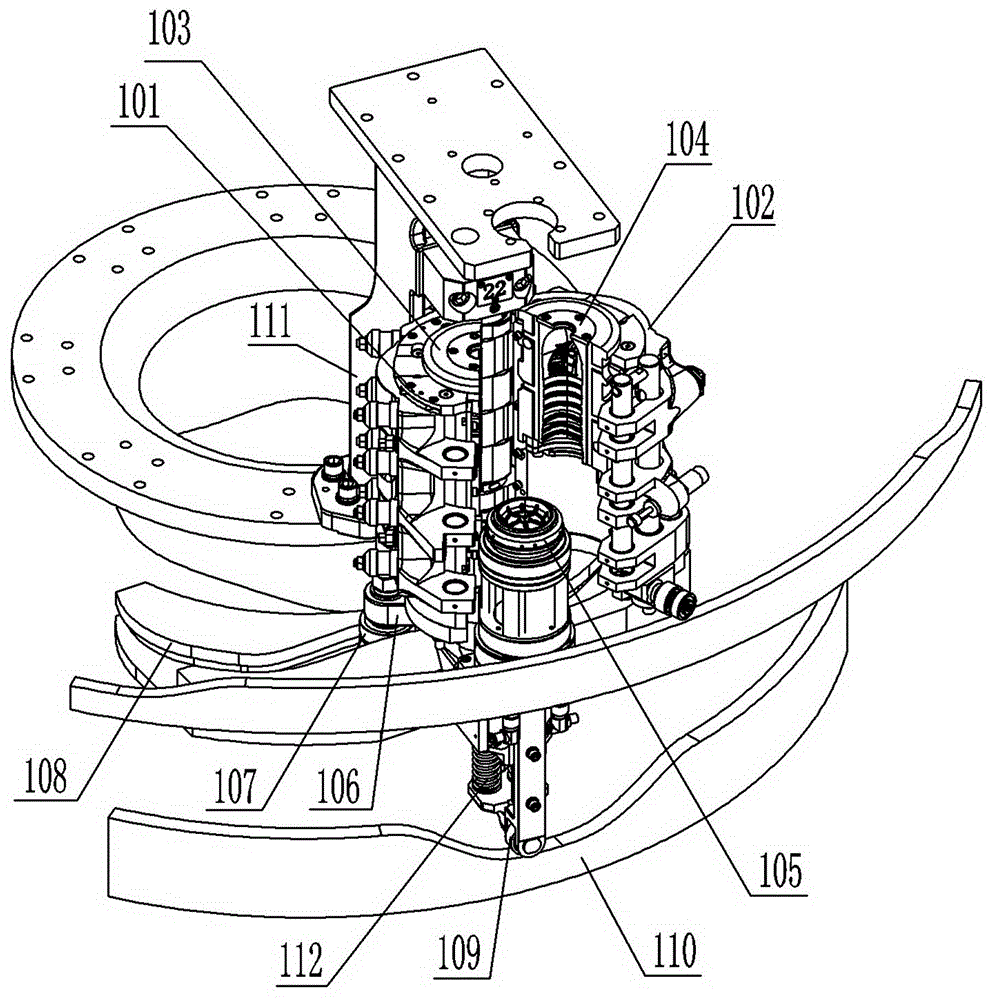

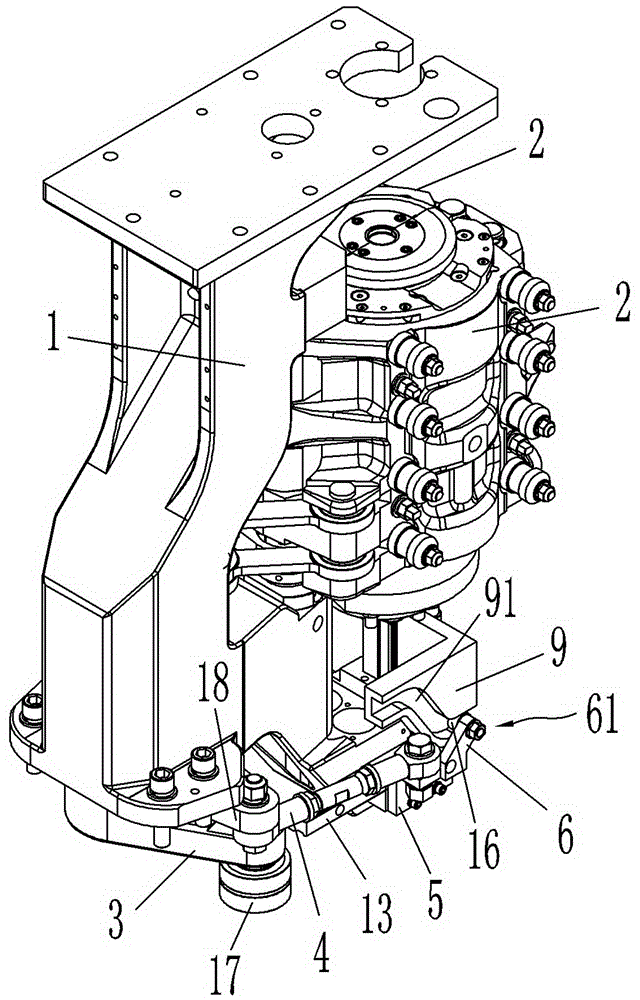

[0011] Such as Figure 3 to Figure 5 As shown, the linkage mechanism for the opening and closing of the mold base of the bottle blowing machine and the lifting of the bottom mold includes a mold base 2 that can swing under the drive of the driving device and drive the mold base bracket 1 of the blow molding machine. The opening and closing mold connecting rod 3 for opening and closing, one end of the joint bearing connecting rod 4 is connected with the opening and closing mold connecting rod 3, and the other end of the joint bearing connecting rod 4 is connected with the slider which can be horizontally slidably installed on the mold frame support 1 5 is connected, and the slider 5 is fixed with a driving seat 6; the bottom mold support 8 for driving the bottom mold 7 to lift is fixed with a bottom mold lifting guide plate 9 with a height drop curve slideway 91, and the driving seat 6 is connected with its end. part can extend into the curved slideway 91 and can slide the driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com