Ship stern boring platform

A stern and boring technology, which is applied to ship components, boring/drilling, and ship construction, can solve problems such as low efficiency, low safety factor of scaffolding, and high long-term cost, so as to avoid safety accidents and achieve good structural stability and construction space, the effect of a good safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

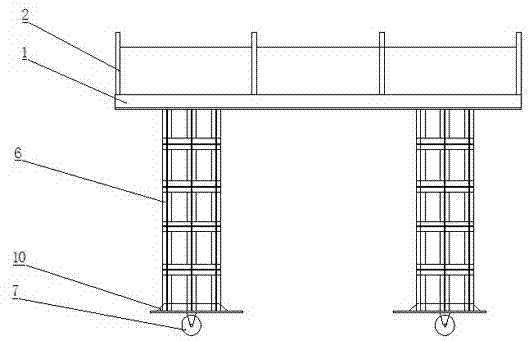

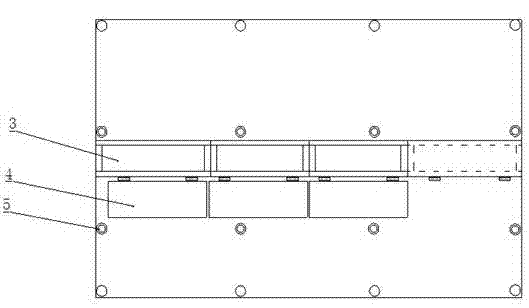

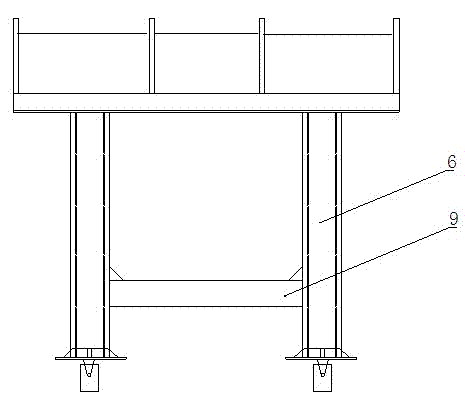

[0021] like figure 1 , 2 , Shown in 3, including working platform 1, movable guardrail 2, backguy lighting channel 3, flap 4, guardrail 5, column 6, pulley 7, lifting lug 10, flatbed truck transport crossbeam 9.

[0022] The above-mentioned steel structure working platform 1 is composed of welded I-beams and angle steels, and the surface of the working platform 1 is laid with anti-skid patterned steel plates. Detachable movable guardrails 2 are arranged around the working platform 1, and protective chains are connected between the movable guardrails 2.

[0023] In the center of the working platform 1, a backguy lighting channel 3 penetrating the surface of the working platform 1 is set, and a safety protection device is set on the backguy lighting channel. The safety protection device is a plurality of flaps 4 that can cover the backguy lighting channel 3, and the flaps 4 are hinged with the working platform 1 on one side of the backguy lighting channel 3.

[0024] The safe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com