A filter spout cup

A filter type and sprue cup technology, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problems of setting filter screens, large impact effects, and broken sand molds, so as to reduce slag inclusion, strong applicability, and reduce The effect of a scum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

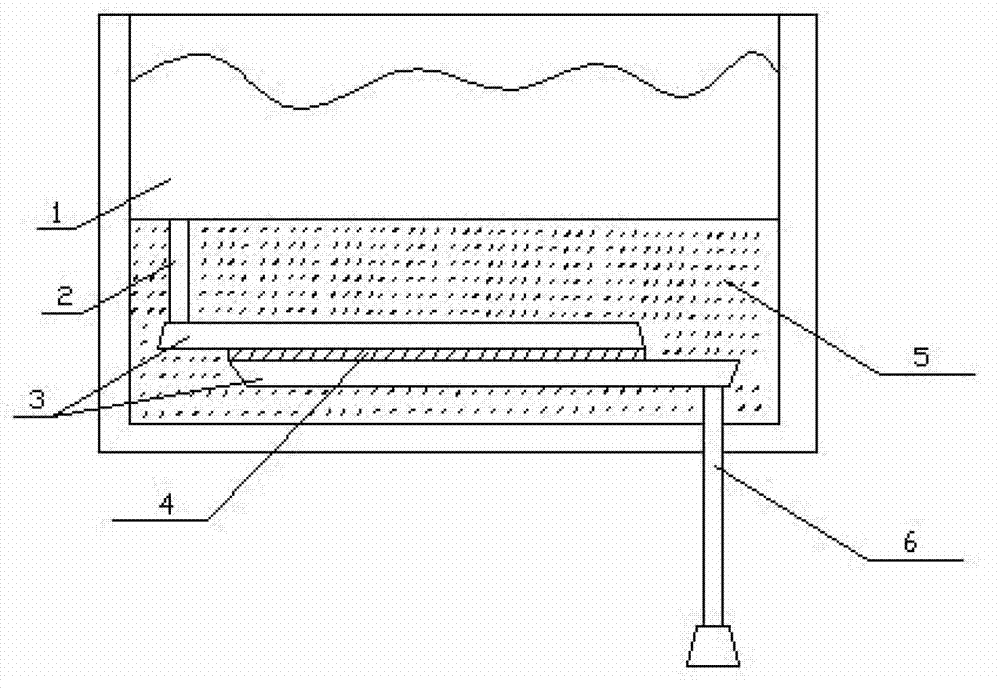

[0018] A filter sprue cup, such as figure 1 As shown: it includes an open sprue cup 1 with an upper part containing molten iron and a lower part of a sand mold 5. A sprue 2 communicating with the molten iron is provided on one side of the sand mold, and the lower part of the sprue 2 is connected with parallel runners in turn. 3. The end of the lowermost runner 3 is connected with a tail sprue 6 corresponding to the above-mentioned sprue 2 that communicates with the casting, and a filter 4 is placed between the above-mentioned runners 3 parallel to each other.

[0019] There are two parallel runners 3 .

[0020] The sprue cup 1 has a rectangular cross-sectional shape, the upper part of the sprue cup accommodates molten iron in a large-volume structure, and the sand mold 5 in the lower part is a solid structure.

[0021] The filter 4 is a honeycomb filter.

[0022] First, according to the weight of molten iron that needs to be filtered, calculate the number of filters that nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com