Efficient continuous type reverse-particle-size filter device and technology

An anti-granularity and high-efficiency technology, which is applied in the direction of filtration separation, gravity filter, loose filter material filter, etc., can solve the problems that the filter bed's pollution interception ability cannot be fully exerted, the filtration cycle is short, and the operating cost is increased. Achieve the effects of prolonging the filter working cycle, uniform loss distribution, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

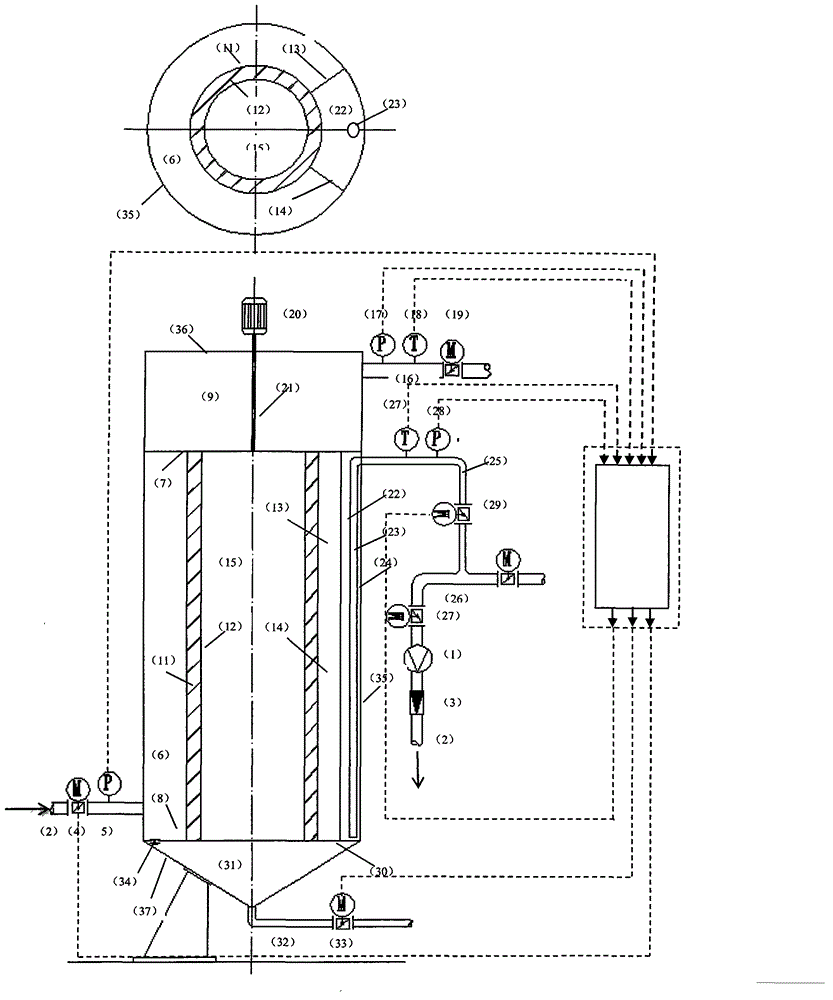

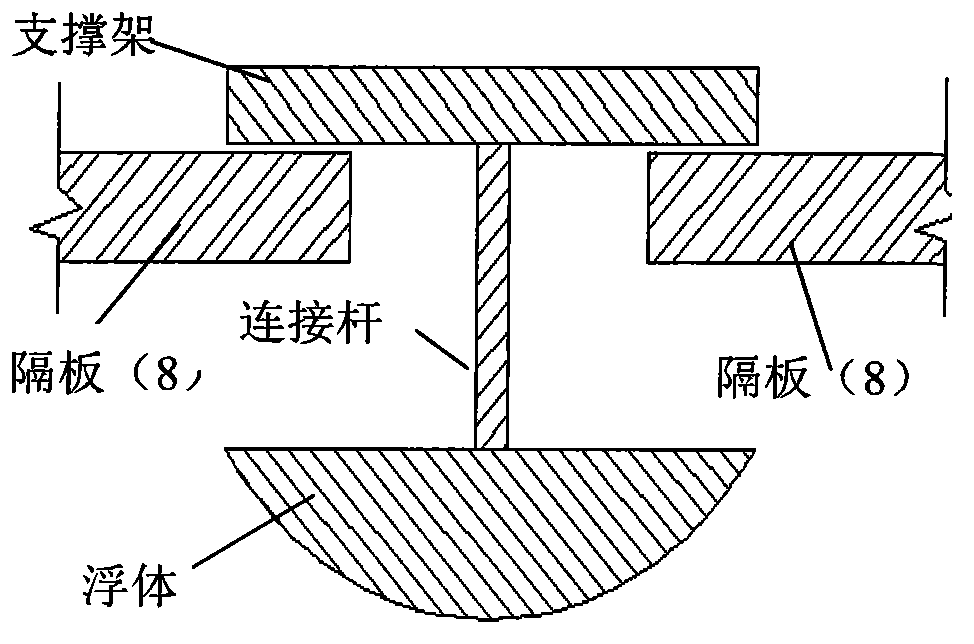

[0027] refer to figure 1 , the present invention includes main equipment, auxiliary pipelines and valve systems, and a measurement and control system. The peripheral structure of the main equipment is surrounded by an outer cylinder (35), a top cover (36) and a bottom plate (37).

[0028] refer to figure 1 , to illustrate the process of process filtration.

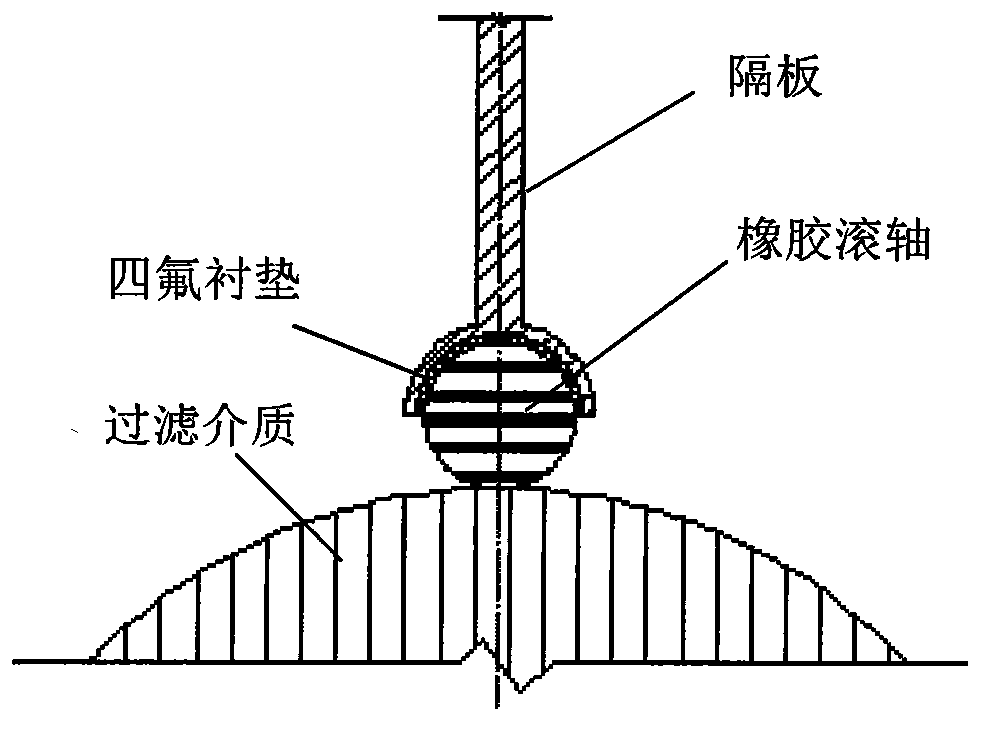

[0029] After the raw water is pressurized by the lifting pump (1), it enters the raw water distribution area (6) of the main equipment through the water inlet pipe (2) through the flow meter (3), solenoid valve (4) and pressure gauge (5). The horizontal partitions (7), (8) are separated from the clear water area (9) and the sludge concentration area (10), and are separated by filter media, columnar grids (12), vertical partitions (13), (14) and filter The rear water collection area (15) is separated, and the filter medium (11) is evenly wrapped on the columnar grid (12). After the raw water enters the water distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com