Field effect transistor and manufacturing method thereof

A field-effect transistor, polysilicon technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as leakage and electrical parameter failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

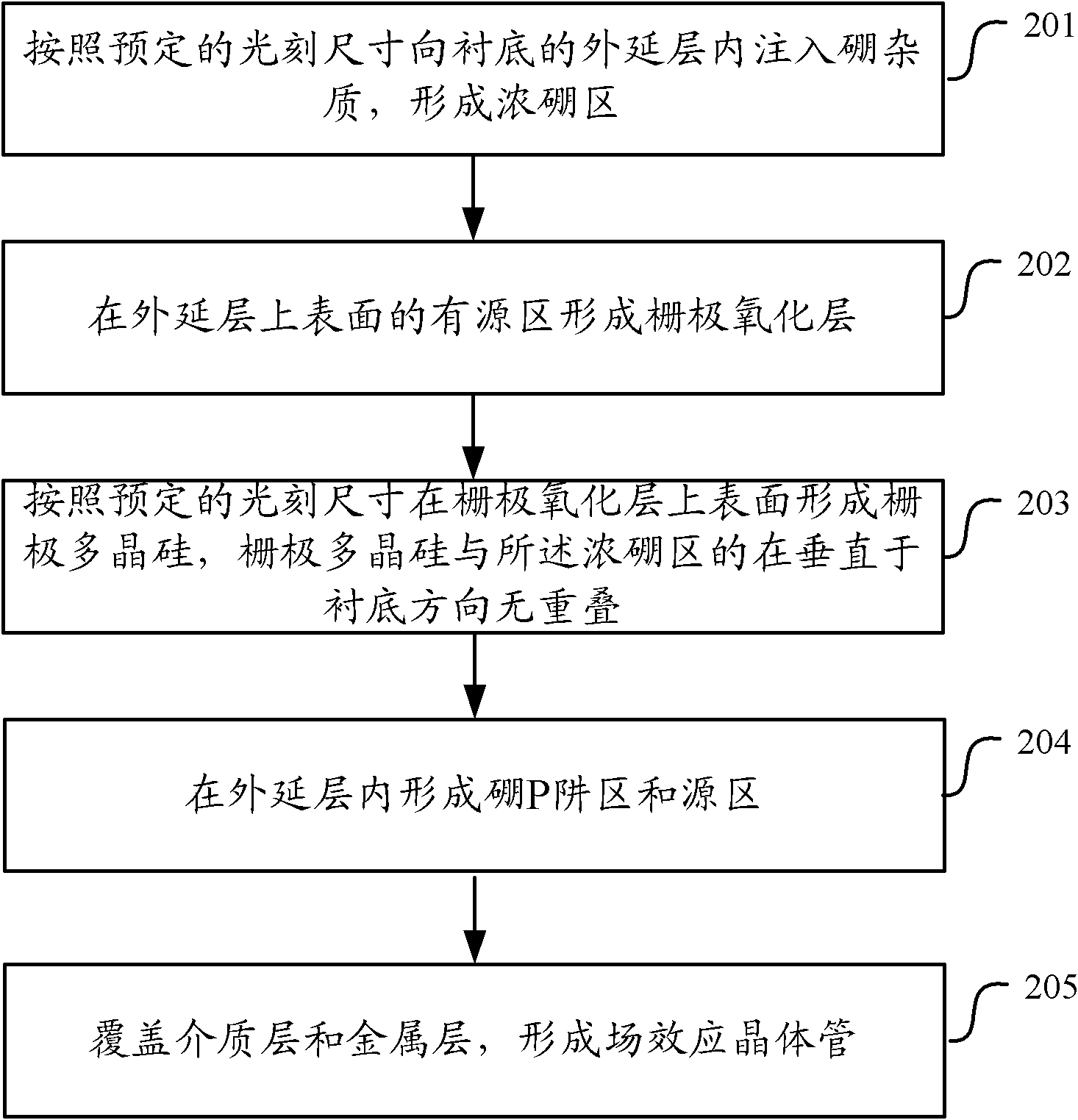

[0039] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

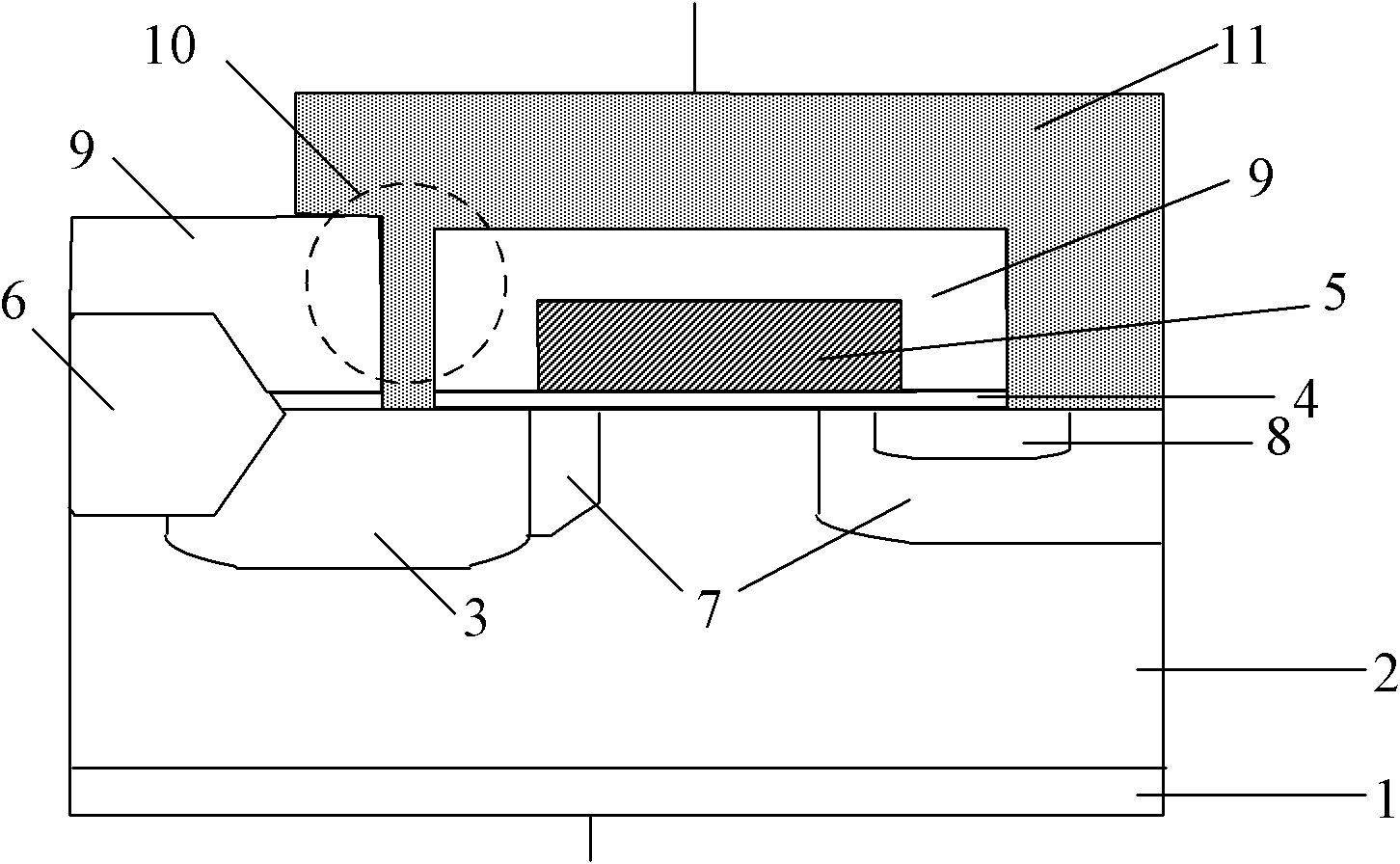

[0040] An embodiment of the present invention provides a field effect transistor, such as figure 1 As shown, the field effect transistor consists of:

[0041] an epitaxial layer 2 located on the upper surface of the substrate 1;

[0042] a boron-rich region 3 located in the epitaxial layer 2;

[0043] A gate oxide layer 4 located in the active region on the upper surface of the epitaxial layer 2;

[0044] Gate polysilicon 5 located on the upper surface of the gate oxide layer 4;

[0045] Wherein, the gate polysilicon 5 does not overlap with the boron-rich region 3 in a direction perpendicular to the substrate 2 .

[0046] Preferably, the field effect transistor further includes: a field oxide layer 6 located in the non-active area on the upper surface of the epitaxial layer 2 .

[0047] Preferably, the field effect transistor further i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com